3D Printing Prototype in Manufacturing: A Complete Guide

3D printing is likewise called additive manufacturing. This is a term used to describe the manufacturing skill of adding layers to the base material. It is the opposite of subtractive manufacturing, where the material is reduced from a block to get the final form. 3D printing is useful in prototyping and low-volume manufacturing. You will certainly locate this manufacturing technique ideal for producing custom-made parts with complex geometries. It can serve a broad range of industries.

This modern technology has actually been around since the 1980s, and also it is currently a vital quick prototyping tool. Technical advancements in 3D printing have seen lots of companies embrace this technology. Its usage and also applications vary from one industry to another. It is mostly made use of to develop tooling aids, aesthetic and also functional models. To create a 3D model or part, you need to make a three-dimensional item by including layers of material. This is a general idea of how 3D printing functions, there is a need to recognize the underlying treatments.

Sunrise Metal Prototyping

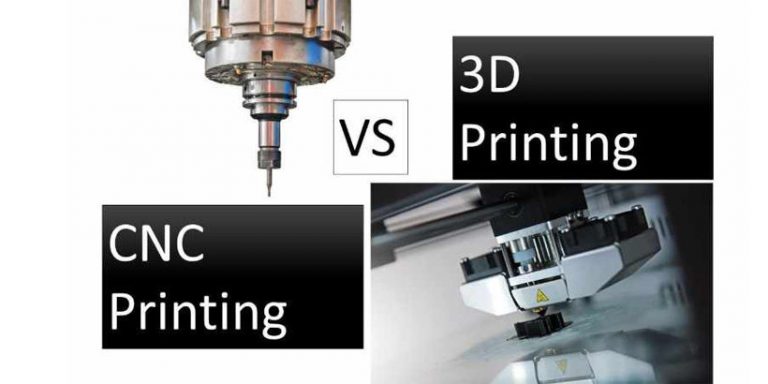

3D printing remains to be a budget-friendly technique of making visual and also functional models. Sunrise Metal integrates additive manufacturing with CNC machining and aluminium die casting to develop personalized models for different markets.

Sunrise Metal boasts a team of designers and also designers who prepare to turn your principle into a truth. Throughout the years, the business has actually grown to become the leading supplier of quick models for inventors and also companies. The company currently provides prototype production solutions, including CNC machining, 3D printing, vacuum casting, and surface finishing.

Sunrise Metal makes every effort to fulfil quality criteria and also go beyond consumer expectations. This is accomplished via:

- Comprehensive criteria of policies, overviews, and procedures.

- Substantial client interactions and keeping digital documents of orders.

- Fully equipped quality control department.

- Non-conformance evaluation and reporting.

- Continuous enhancement system.

- Training of designers and also designers regularly.

With the huge investment in quality assurance and assessment, you can be ensured premium prototypes. Whether you are seeking practical products or quick prototypes, Sunrise Metal is in a placement to meet your needs.

The procedure of getting quick models can be done online. You just need to get in touch with the customer care division, and they can take you through the whole procedure.

What Are The Applications of 3D Printing Prototypes?

Automotive

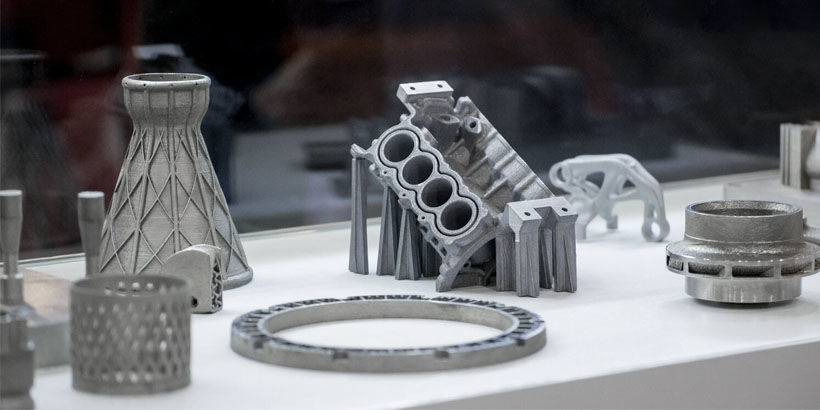

This is an additional area where 3D published models are being used. Although prototyping is the main use 3D printing innovation, some business is now using it for tooling.

Since quick prototyping plays a critical duty in the item development process, it provides a method of testing and confirming components. It offers a fast as well as an economical method to make components. This innovation is now utilized to make spare as well as replacement components.

Medical

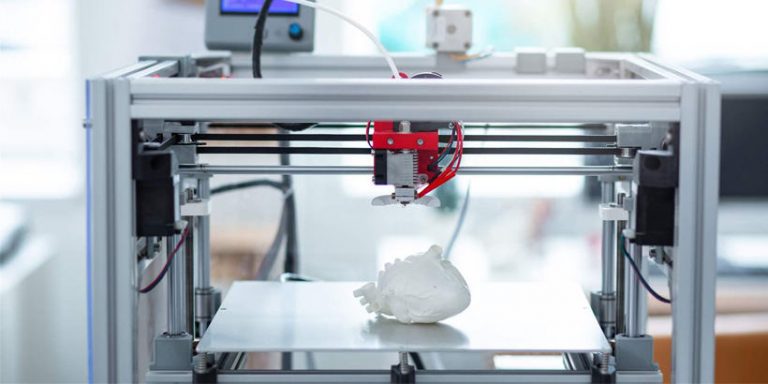

3D printing is used in making prosthetics. Applications of 3D published models in this sector are versatile and also wide-ranging.

Aerospace and Protection

This sector has actually been utilizing 3D published models for years, adding to constant study in this field. In this sector, 3D printing is utilized to produce:

- Lightweight components.

- Tooling.

- Useful prototypes.

You should note that 3D printing is not limited to making models in aerospace as well as defence, yet additionally useful components. For instance, air ducts and also wall panels can be made via 3D printing.

Pros of 3D Printing Prototype in Manufacturing

Rate

When you use 3D printing in fast prototyping, you can design, create, and also test a prototype as rapidly as possible. You can change the style without negatively delaying the prototyping procedure. In the past, prototyping would take several weeks. That is because, with any kind of additional adjustment, the time to generate a model would certainly raise. You will certainly discover this to be significant if you are running a tiny or medium business.

Consistency

Conventional prototyping procedures can result in some parts being irregular in top quality or faulty. Thankfully, in 3D printing, you can check the parts and also find errors in real-time. This way, you can minimize the number of faulty components and avoid product waste.

Flexible

The various other factors you need to embrace 3D printing prototypes is that you can make virtually anything possible within its construct quantity. This is not the instance with typical prototyping procedures, where adjustments in design need new devices or mould and mildews to be made.

With 3D printing, you can manufacture complicated geometries that are impossible with conventional prototyping techniques. For example, you can include hollow tooth cavities in solid components.

Decreased Cost

You will discover 3D printing to be an affordable manufacturing procedure. Considering that you are creating the prototype from the ground up, there is minimal material wastefulness and does not need added tooling.

Cons of 3D Printing Prototype in Manufacturing

Needs Extra Processing

Most of the 3D printing models call for additional processes to get rid of the material to attain the wanted surface. Some procedures such as CNC machining, paint, anodizing, and a lot more can be done. Although 3D printing prototyping is quicker, its rate can be slowed by added processing.

Limited Build Size

The fact is that 3D printers have small-sized print chambers. Consequently, the dimension of prototypes made is restricted. If you wish to publish a bigger model, you will certainly be forced to do it in different components and afterwards join them after manufacturing.

Design Mistakes

The various other problem with 3D printing is that precision depends on the additive production procedure or maker made use of. As an example, some printers have reduced resistances. This means that the final components can differ from the initial design. You can repair this with surface area finishing, yet this increases the expense of production as well as preparation.

Limited Materials

You can make use of 3D printing to produce models in different metals as well as plastics, you are restricted to the products you can use. Since not all plastics, as well as metals, can be temperature-controlled for 3D printing, that is. Some of the materials used can not be reused.