Advances In Materials Science And Their Impact On Mechanical Engineering

Hey there, have you ever wondered how the machines we use every day work? Mechanical engineering is a field that deals with designing and building mechanisms and systems that make our lives easier. But what makes these machines durable and efficient? The answer lies in materials science.

Over the years, advances in materials science have revolutionized mechanical engineering by providing new ways to design and create sturdy, lightweight, and high-performance components for various applications.

In this article, we’ll explore some of the latest developments in materials science that are transforming the way engineers think about mechanical design. From smart alloys to cutting-edge composites, we’ll take a closer look at how these innovative materials are changing the game when it comes to modernizing mechanical systems.

So buckle up and get ready for an exciting ride through the world of materials science!

Smart Alloys

As a mechanical engineer, I am constantly amazed by the latest advancements in materials science. One particular area that has caught my attention is smart alloys. These are materials that can change their properties based on external stimuli, such as temperature or stress. Smart alloys have numerous applications in engineering, from aerospace to biomedical devices.

Another exciting development in the field of materials science is nanocomposites these are materials made up of nanoparticles and polymers that offer improved strength and durability compared to traditional materials.

Additionally, smart coatings are being developed that can respond to changes in their environment by changing colour or texture. It’s incredible how much innovation is happening within this field, and I can’t wait to see what other breakthroughs will emerge in the future.

Carbon Nanotubes And Graphene

So let’s talk about carbon nanotubes and graphene, two of the most fascinating materials in the world of advanced engineering.

These super-strong, ultra-lightweight substances have revolutionized mechanical engineering in countless ways, from building stronger and more durable structures to creating faster and more efficient electronic devices.

One of the biggest impacts they’ve had is in the field of nanocomposites, where tiny amounts of these materials are added to other substances to greatly enhance their strength and resilience.

This has led to a whole new era of nanoengineering, where researchers are able to design and create incredibly precise structures that were once thought impossible.

With so much potential for innovation, it’s clear that carbon nanotubes and graphene will continue to play a major role in shaping the future of materials science for years to come.

Polymers And Plastics

When we think of plastics, we often imagine materials that sit in landfills for hundreds of years. However, with the advent of biobased plastics and bioplastics, this is changing rapidly.

These types of plastics are made from renewable resources like cornstarch, sugarcane, and even algae. Biobased plastics have been around for a while now but it’s only recently that they’ve gained popularity as an alternative to traditional petroleum-based polymers.

One significant advantage of these new polymers is their reduced carbon footprint compared to conventional plastic production methods. For instance, producing one kilogram of bio-based polyethylene requires 1-3 kilograms less greenhouse gas emissions than its petroleum counterpart.

Another benefit is their potential recyclability¡ªbioplastics can be composted under certain conditions or converted into fuels through chemical processes known as depolymerization.

While there are still some challenges associated with using biobased plastics on a large scale (like their higher cost), I believe that as technology advances further in this field, we’ll see more and more applications for these innovative materials in the future.

It’s exciting to think about how much impact this could potentially have not just on mechanical engineering but also on our planet¡¯s overall health and sustainability!

Advanced Composites

Imagine a material that is incredibly strong and lightweight, capable of withstanding immense pressure and stress without breaking.

This is the promise of advanced composites, which have been developed thanks to recent advances in materials science.

These materials are made up of two or more components, such as fibers and resins, that work together to create a stronger whole.

They can be tailored for specific applications by adjusting the type and amount of each component used.

One exciting area of development is the use of nanocomposites, which incorporate tiny particles into the material to enhance its properties even further.

Another promising field is biocomposites, which use natural materials like bamboo fibers instead of synthetic ones.

As mechanical engineers continue to explore these new materials, we may see them being used in everything from airplanes to medical implants revolutionizing industries and changing lives without sacrificing strength or durability.

Ceramics And Glasses

I’m excited to talk about the advances in Ceramics and Glasses and their impact on mechanical engineering. Manufacturing of Ceramics and Glasses has come a long way, and their properties have been improved drastically. I’m sure we can explore the various applications of these materials and how they’ve revolutionized mechanical engineering.

Manufacturing Of Ceramics And Glasses

I’m really excited about the manufacturing of ceramics and glasses! It’s amazing how advances in technology have made it possible to create these materials with such precision.

One breakthrough has been the use of nanoparticles, which allows for even smaller and more uniform particles to be used in production.

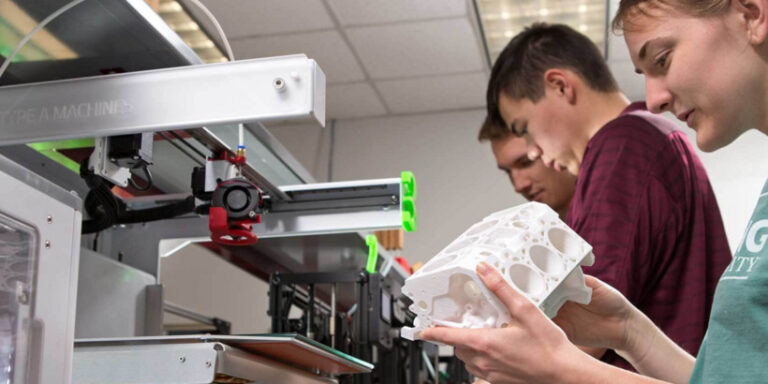

And let’s not forget about 3D printing, which is revolutionizing the way we think about manufacturing altogether. With this technology, it’s now possible to create complex shapes and designs that were once impossible using traditional methods.

All in all, I can’t wait to see what other advancements will come out of this field in the future.

Properties Of Ceramics And Glasses

So, we’ve talked about the manufacturing of ceramics and glasses in previous subtopics. Now, let’s delve into their properties.

Ceramics and glasses have unique characteristics that make them stand out from other materials. For instance, they both possess crystal lattices which are highly ordered arrangements of atoms within a material’s structure. This gives them strength and durability compared to other materials such as plastics or metals that lack this feature.

Additionally, the atomic bonds between these crystals give rise to their high melting points and resistance to heat and chemicals. It’s fascinating how the arrangement of atoms at the molecular level can greatly affect a material’s physical properties!

There is so much more to explore when it comes to understanding the properties of ceramics and glasses; with each discovery bringing us closer to unlocking their full potential.

Applications Of Ceramics And Glasses

Now that we’ve talked about the properties of ceramics and glasses, let’s explore their diverse applications.

From everyday items like coffee mugs to advanced technologies such as aerospace components, ceramics and glasses play a significant role in our lives.

But did you know that scientists are also exploring protein-based ceramics for biomedical implants? These materials have the potential to be biocompatible with human tissues, making them ideal candidates for bone grafts or other medical devices.

And let’s not forget nanocrystalline glasses which have unique optical properties that make them suitable for high-tech applications such as lasers and photonic devices.

It’s exciting to see how these materials can be tailored to suit various industries and pave the way for new discoveries.

Metamaterials

Nowadays, metamaterials are becoming increasingly popular in materials science and mechanical engineering. These artificial structures have unique properties that cannot be found in natural materials, such as negative refractive index or electromagnetic invisibility.

One of their most remarkable applications is the development of supersonic waveguides. Metamaterials can manipulate sound waves to create a channel where they can propagate without losing energy or scattering. This technology has potential uses in aerospace engineering, allowing for quieter aircraft engines and faster-than-sound travel.

Another exciting field where metamaterials could revolutionize is magneto dielectrics. By combining magnetic and electric properties, these materials offer great performance for communication devices and power transmission lines. They also enable new technologies such as transformation optics, which allows controlling light propagation at will by bending space itself.

It’s clear that metamaterials are opening up a whole new range of possibilities for engineers and scientists alike, and we’re only starting to scratch the surface of what they can accomplish.

Shape Memory Alloys

Now let’s talk about one of the most fascinating materials in mechanical engineering – Shape Memory Alloys (SMAs). These alloys have made a significant impact on how we design and develop various products.

SMAs are special types of metals that exhibit unique properties when subjected to thermal or mechanical loading conditions. One such property is their ability to remember their original shape after undergoing deformation, which occurs due to martensitic transformations. This capability has been utilized in numerous applications, including aerospace, biomedical, and automotive industries.

However, there are some hysteresis effects associated with SMAs that need to be carefully considered during their application. Hysteresis can cause energy loss and affect the accuracy of the system where these alloys are integrated. Therefore, researchers are continuously working towards improving SMA performance by reducing these effects.

In summary, SMAs offer exciting possibilities for designing new products with novel capabilities. With ongoing research efforts aimed at understanding their behavior and developing better manufacturing processes, it’s only a matter of time before we see more widespread use of SMAs across different fields without worrying about hysteresis effects or other limitations.

Conclusion

In conclusion, the advancements in materials science have had a significant impact on mechanical engineering. From smart alloys that can change shape and properties when exposed to stimuli, to carbon nanotubes and graphene with unmatched strength-to-weight ratio, these new materials enable engineers to design more efficient machines and structures.

One example of this is the story of my friend who works in aerospace engineering. He shared how they were able to reduce the weight of an airplane by using advanced composites such as carbon fiber-reinforced polymers (CFRP) instead of traditional metal alloys. This led to reduced fuel consumption and increased flight range, ultimately benefiting both the environment and airline companies’ bottom line.

Furthermore, I believe that these advances also represent a metaphor for progress itself. Just as scientists are discovering new ways to manipulate molecules at the atomic level to create stronger and smarter materials, we too can use technology and innovation to push beyond our current limitations and achieve great things.

The possibilities seem endless, from building taller skyscrapers made of ultra-strong ceramics or creating flexible electronics out of metamaterials. It’s exciting to think about what might be possible in the future with continued research into materials science!