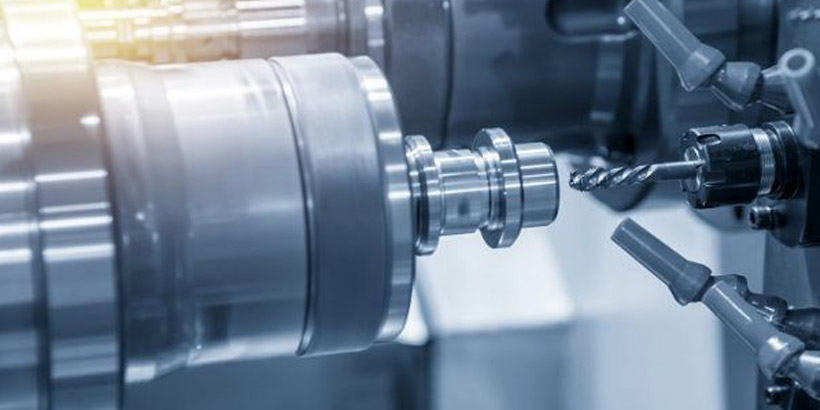

Guide to Enter Into CNC Machining Process

The greatest advantage of the CNC machine is its automated machining based upon the programming series, which mostly saves time and also improves performance, along with minimizes mistakes during the manufacturing. Just how does the CNC machining procedure work and also just how to get into CNC machining for hobbyists? Hope the following CNC tutorial for novices can bring you closer to the technique.

CNC Tutorial for Novices

Here is the fundamental procedure from CNC layout to the finished component, in real operations, there will be even more details and also configurations that related to the intricacy of the CNC components. The adhering to actions discuss how the CNC machining procedure functions.

Style the CNC parts you intend to produce

The first thing you need to do is create a design or style of what you intend to make, either 3D or 2D. For 2D drawings, DXF is the usual format, while for 3D designs, the format is relying on what software program you use. Generally, AutoCAD and also Blend 360 are frequently made use of CAD software programs.

Transform the model/design right into directions

The motions of CNC machines are based on the set directions, if you simply send the version files to your CNC turret or mill, it does not recognize what to do and also exactly how to do it. Every CNC has a couple of various controllers and also each maker understands the code a bit in a different way as well as requires some various specifications.

Use CAM software to take your design, designate different tools as well as types of machining procedures to certain elements of the layout as well as compute the tool path, which is the path the devices will follow in order to cut a work surface.

Transform your computer to a CNC machine controller

Currently, most CNC machines are controlled by a computer system or some sort of specialized controller, which is typically made use of for a lot more high-end or pricey designs. For beginners, a computer with software that attaches to your CNC suffices. Choose a CNC control software to turn your computer into a CNC machine controller, Mach3 is an excellent choice for newbies and enthusiasts.

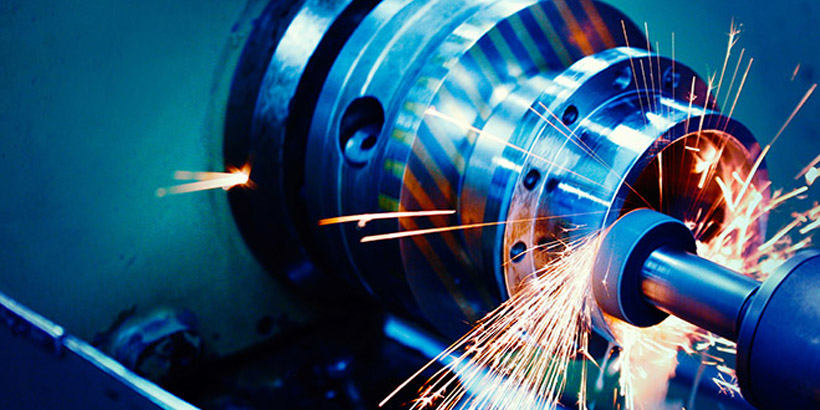

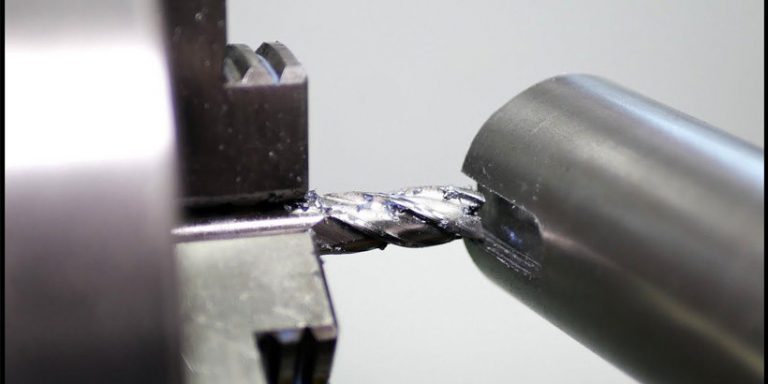

Machining process

The software application requires managing the CNC and established absolutely no factor, you need to tell the machine where you want absolutely no points to be about and choose the factor as the product design. Move your device to the no point, maintain your eye on the maker, as well as there, are some tools that enable you to discover the factor exactly. Tell the software program where it is no and also when you start your code by just pushing cycle start, the software program sends out the codes to the device, and also the entire process can start.

How to Beginning CNC Machining

CNC is a wide expertise demand that takes a long time to proceed as well as examine in practice. Below are just some key points in finding out CNC machining.

- Style the necessary part is the first step in CNC, you can use numerous CAD software applications to finish it or download cost-free CAD data after that modify it for manufacturing requirements. If are strange to the area, DEK likewise gives CNC design solutions for industrial components in various industries, welcome to contact us for any kind of demands.

- Find out about CNC shows. CNC programming can be extremely complicated, for novices, you can check some CNC programming examples initially to recognize the significance of M-codes and also g-codes, in addition to how it works.

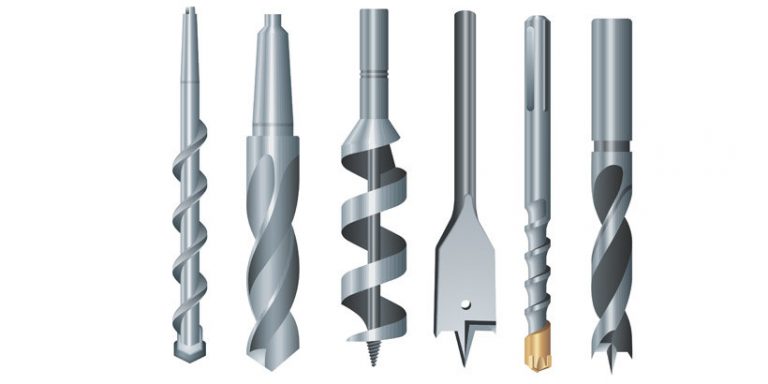

- Discover the parts and building and construction of CNC machines. CNC machines like lathes, drills, routers, and also mills are all the tools to complete the machining procedures on the product stock, get to know what is the device composed of, and also the feature of each element.

- CNC machine setup is what we get the maker all set to run the component, ensure all the right tools in the device changer, and best instructions are filled.

- The typical troubleshooting, as well as upkeep of the CNC machine, are also crucial.

Summary

How does CNC machining process job and also how to obtain into CNC machining for enthusiasts? The movements of CNC machines are based on the set guidelines, if you simply send out the model files to your CNC turret or mill, it does not understand what to do and just how to do it. Choose a CNC control software to turn your computer right into a CNC machine controller, Mach3 is a great option for hobbyists and novices.

CNC programming can be really complicated, for beginners, you can check some CNC programming instances initially to recognize the significance of M-codes and also g-codes, as well as just how it functions.

CNC machines like turrets, drills, routers, and also mills are all the devices to complete the machining procedures on the product stock, get to know what is the device made up of as well as the function of each part.