Summary to Straightness

Straightness is a vital term to establish whether CNC machined parts comply with the called for requirements. What is straightness and how to determine it? In this article, we describe the surface area straightness interpretation, GD&T icon, expression, dimension, and also a difference between monotony and similarity.

What is Straightness?

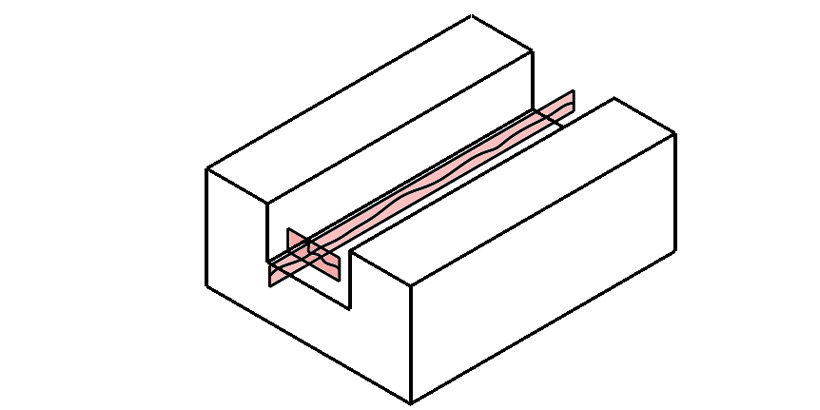

Straightness is a type of form resistance introduced in GD&T, it can be defined as the level to which a line element can deviate from its perfectness. To simply recognize straightness, if we have a level plate as well as the straightness applied to the top surface area is 0.100, consider its side sight or reduce any type of cross-section along with its length, the upper line of the cross-section stands for the leading surface intersects this area aircraft, that line can not differ ideal straightness by more than the tolerance.

The basic kind of straightness is a 2-dimensional tolerance that is used to guarantee the surface area of a part is uniform, there is also axis straightness used to manage the main axis of a part.

Set a fictional border as below, it represents the resistance area, as well as the dimension of that, is going to be one hundred countless an inch, which is expressed by the value in the resistance framework. The line stands for the junction of the top surface of the plate as well as the area aircraft can be any shape within this resistance border.

Exactly How to Measure Straightness

Comparing these 2 measurement methods, the coordinate measuring machine is more versatile and also accurate, while it needs to take lots of costs, using an elevation scale has even more restrictions but it’s much cheaper.

- Use gauge procedures along a straight line to examine just how level or straight the line is along this surface area by measuring the elevation variant. Ensure the challenge be measured is dealt with so that the elevation is evenly matched left-wing as well as right. The difference between the maximum and also minimum worths is straightness.

- Use a coordinate measuring device (CMM) to gauge the straightness as long as the driver places the stylus gently on the object to be measured. CMM devices can likewise be made use of to determine the part that can not be protected degree (an elevation gauge can’t do that).

Distinction Between Straightness and Parallelism

- There is a datum for parallelism dimension, while the measurement of straightness is no referral.

- The similarity is the distance between two parallel aircraft contrasted to the datum. Straightness is the range in between the highest point and the most affordable point on a straight line.

Distinction In Between Straightness and Flatness

- Flatness is a home of a plane, while straightness is the account of a line.

- Straightness can be regarded as the 2D variation of flatness.

- Flatness measures the variance across a 2-dimensional airplane, straightness just determines the difference on a straight line.

- A level aircraft does not differ up and down but can be curved, a straight line does not differ left or appropriate.