The Factor Why Casting Parts Are More Probable To Have Imperfections

The web has lots of discussions over which components are better. Cast or forged, it matters not if you’re discussing gun components or vehicle components, it appears that the overwhelming agreement is built parts are much better. put simply, cast parts are weaker since they have all these spaces in them they have no grain structure. there’s no company, it simply looks all careless. if you were to look through it with a microscope. you will see that it’s really porous and it sort of appears like a sponge.

Why does this happen? well, in the casting procedure as well as allow’s take into consideration that we have the best mold. One side is not cooling faster than the opposite, the thickness of the steel that’s being poured is ideal, we’re chatting a casting process at its highest possible high quality. there are still going to be nullified therein. as the steel is cooling from the outdoors to the within. points called dendrites are going to create and also they look sort of like snows. as they cool down, they will form grains, however, the grains are not in any type of order, there’s some are little, as well as some allow, or even crude, great, etc. They’re creating these voids, as well as even if we have whatever excellent, there are still will be nullified. and that’s why spreading doesn’t create a really solid item.

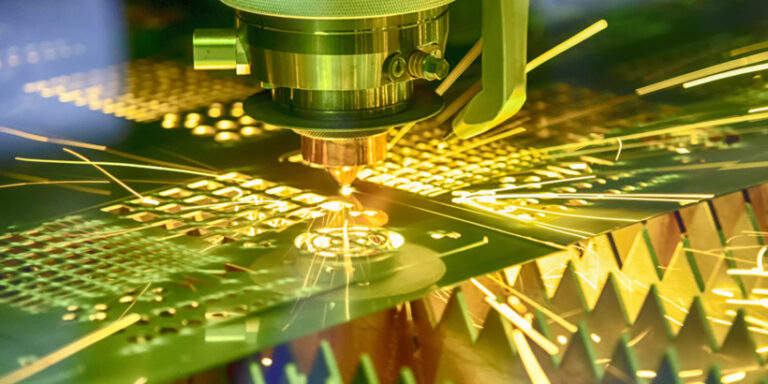

Billet

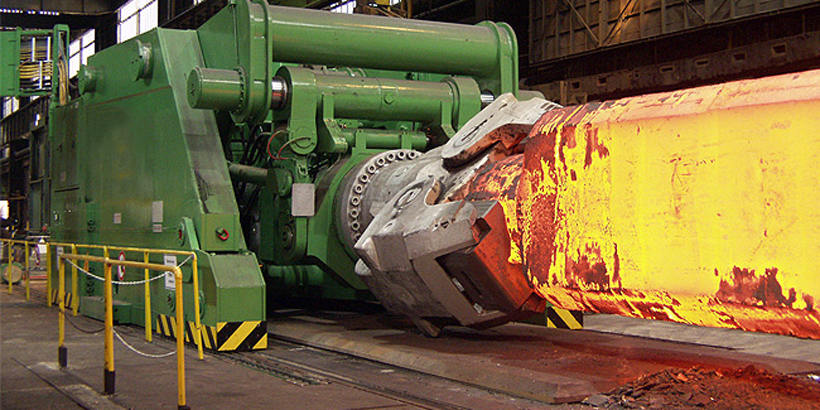

Is Casting great for other points? Indeed, but for gun parts that are under high stress, it’s not the most effective decision. which’s where a billet enters into play. we know we need to have something with a good grain structure. how do you obtain that fluid steel into a billet? it’s pretty easy, rather than putting it, all they’re doing is they’re cool down that liquid steel, slide it down this chute, to make sure that it’s sort of in the form of a rectangular tube and also as it’s decreasing, it’ll hit these rollers called the warm roll, as well as a warm roll, is squeeze that steel straight via it. it’ll align all these grains and wreck off a lot of the voids.

Forging

If you want to stop at the first procedure, you would have a billet and also then from there you have to choose if you want to come in there as well as a mill or cut out the shape that you desire or once you have the billet, build it down into the form that you need and also after that mill it. It’ll do an extra strengthening procedure when you’re using this method. That’s the major difference that this separates itself from various other methods.

Finally

Well, for cast components if you’re making light manufacturing, something that does not have a great deal of stress taking place it, make use of a cast part, because you can get it to be extremely detailed for a really affordable cost, it’s really affordable to make use of casting for those types components. the billets that are machined or milled out, you can see spikes tactical that’s an excellent example for air 15 receivers, they obtained heads and also the plane, and all they’re doing is they’re taking the billet as well as they’re milling out what they need which can get detailed as well. It’s not the best. what you wish to do is simply forge whatever you’re doing so that you can keep the continual grain framework. If you want to know, please contact us.