The Impact Of Automation On The Manufacturing Industry

Automation has been a buzzword in the manufacturing industry for several years now. It refers to the process of using machines and technology instead of human labor to perform tasks.

While automation is not new, its impact on the manufacturing industry has never been greater than it is today. In this article, I will explore the effects that automation has had on manufacturing, both positive and negative.

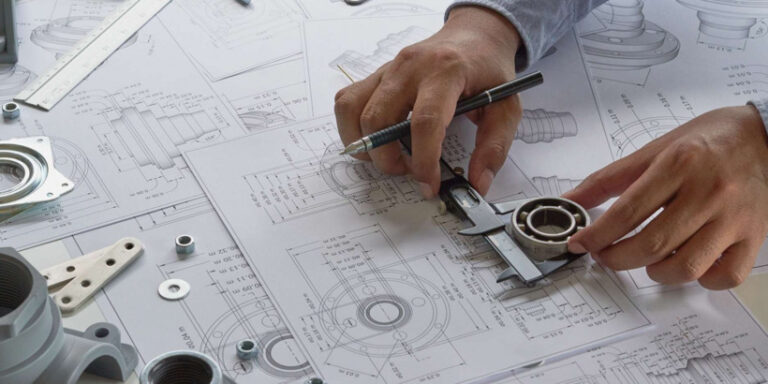

It’s impossible to discuss the current state of manufacturing without mentioning automation. The use of robots and other automated systems has revolutionized production processes across various industries, from automotive to food processing.

While some people view automation as a job killer, others see it as an opportunity to improve efficiency and reduce costs. Regardless of your perspective, there’s no denying that automation has transformed how we produce goods in ways that were once unimaginable.

Increased Efficiency

Automation has revolutionized the manufacturing industry, and its impact is undeniable.

It’s like having your own personal assistant that takes care of all the mundane tasks, leaving you with more time to focus on important matters.

With optimized processes, automation has increased efficiency in the factory floor by reducing waste and streamlining production.

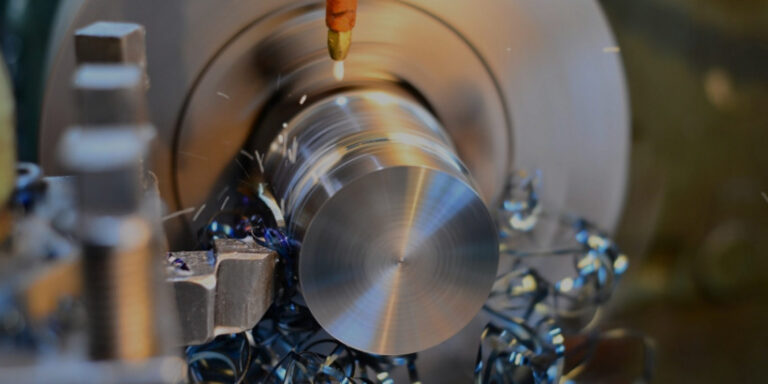

No longer are we bogged down by tedious manual labor; instead, machines take over and do it better than humans ever could.

And this isn’t just about saving time – it¡¯s also about improving quality standards while cutting costs at the same time.

The benefits of automation cannot be overstated, and as a result, many companies have already started implementing these technological advancements into their operations without hesitation or delay.

Reduced Labor Costs

When it comes to the impact of automation on the manufacturing industry, reduced labor costs are a significant benefit.

By automating certain processes, companies can save money on salaries and benefits for employees who would otherwise be performing those tasks.

Cost savings aside, automation also allows for better labor optimization within a company.

Rather than assigning workers to repetitive or dangerous tasks, they can focus their skills and expertise on more complex projects that require human intervention.

This not only improves efficiency but also enhances overall job satisfaction among employees.

Ultimately, reducing labor costs through automation is just one way in which technology is changing the face of modern manufacturing and it’s clear that these changes are here to stay.

Improved Quality

I’m interested in discussing the impact of automation on the manufacturing industry and how it has improved quality. In particular, I’d like to focus on how automation has increased efficiency, as well as how it’s reduced costs.

Increased Efficiency

I’ve always been fascinated by the manufacturing industry and how it has evolved over time.

With the introduction of automation, we’re seeing a major shift in the way things are done.

One aspect that stands out to me is the increased efficiency that comes with automation.

By using machines that can operate 24/7 without breaks, manufacturers can produce more goods in less time.

This means lower labor costs and an overall reduction in production expenses.

In addition, machine learning allows for continuous improvement in processes which leads to even greater efficiencies.

It’s amazing to think about how much more productive we can be thanks to these advancements!

Reduced Costs

Now, let’s talk about how automation can improve the quality of products while reducing costs.

Personally, I believe that one of the key benefits of automation is smart scheduling. With machines working around the clock, manufacturers can produce goods faster and more consistently than with human labor. This means less time spent on production and fewer errors due to fatigue or inconsistency in work output.

Additionally, data analytics can help identify areas for improvement in manufacturing processes which leads to better product quality over time. By optimizing production workflows based on real-time data, manufacturers can reduce waste and save money on raw materials as well.

It’s exciting to see how technology continues to revolutionize the manufacturing industry by improving both efficiency and quality simultaneously!

Enhanced Safety

As we’ve discussed in the previous section, automation has greatly improved the quality of manufacturing processes. However, it’s not just about producing high-quality products – safety is also a top priority in any industry.

With automation comes enhanced visibility and optimized processes that can help prevent accidents and keep workers safe. By using sensors and cameras to monitor equipment and detect potential hazards, machines can be shut down or adjusted before any harm is done.

This not only protects employees but also reduces downtime due to accidents or repairs. In addition, automated systems can handle dangerous tasks such as heavy lifting or toxic chemical exposure, further reducing risk for workers.

Overall, the integration of automation technology into manufacturing operations not only improves efficiency and quality but also prioritizes worker safety.

Shorter Lead Times

As I stood in front of the factory, watching the machines churn out product after product, it struck me how much faster everything seemed to be.

Shorter lead times have become a reality thanks to automation and its ability to create streamlined processes that can produce predictable outcomes.

With fewer errors and more efficient workflows, manufacturers are able to meet their customers’ demands quicker than ever before.

This has resulted in increased customer satisfaction and improved supply chain management.

As technology continues to advance, we can expect even shorter lead times and an increasingly responsive manufacturing industry.

Increased Productivity

I’m really interested in the impact of automation on the manufacturing industry, especially when it comes to increased productivity! Reducing labor costs, improving quality and increasing efficiency are all great benefits that come with automation. I’m curious to find out more about how automation is helping businesses save money and time.

Reduced Labor Costs

When it comes to automation’s impact on the manufacturing industry, reduced labor costs are a significant benefit.

As someone who has worked in this field for years, I’ve seen firsthand how expensive it can be to hire and train employees.

With automation, however, companies can save money by relying more heavily on machines and robots to complete various tasks.

This cost savings is particularly important when you consider that many businesses operate on thin profit margins.

By reducing labor expenses through increased productivity via automation, these organizations can stay competitive while still producing high-quality goods.

Improved Quality

Now, another benefit of increased productivity through automation is the improved quality of products.

As someone who has witnessed firsthand how human error can impact product quality, I know how crucial it is to have consistent and accurate results in manufacturing.

With automation, machines can perform tasks with enhanced accuracy and precision compared to manual labor.

Moreover, robots are not susceptible to fatigue or distractions that can affect workers’ performance, leading to improved consistency in production output.

This ultimately leads to higher-quality goods that meet customer expectations while reducing waste and rework costs.

Increased Efficiency

Now, let’s talk about increased efficiency as another benefit of automation.

I personally believe that time is precious, and anything we can do to save it should be welcomed with open arms.

Automation benefits us by reducing the amount of time required for a task while improving productivity levels simultaneously.

This directly translates into cost savings for businesses because they can produce more in less time, which means higher profits overall.

With machines taking on repetitive tasks, workers have more time to focus on complex or creative projects that require human input.

This approach optimizes resources and ensures that every minute spent is maximized towards achieving business goals.

Greater Flexibility

As I mentioned earlier, automation has led to increased productivity in the manufacturing industry. However, it has also brought about greater flexibility in the way businesses operate. With streamlined processes and reduced complexity, manufacturers can now easily adapt to changing market demands and consumer preferences.

Here are five ways that automation has enabled this shift towards greater flexibility:

- Reduced setup times: Automated machines allow for faster setup times, reducing downtime between production runs.

- Customization capabilities: Automation allows for customization of products without sacrificing efficiency or speed.

- Remote monitoring: Manufacturers can monitor their automated systems remotely, allowing them to make adjustments from anywhere at any time.

- Predictive maintenance: Automated systems can predict when equipment will need maintenance before a breakdown occurs, minimizing unplanned downtime.

- Rapid prototyping: Automation enables rapid prototyping, which speeds up product development and helps bring new products to market quicker.

With these benefits of automation comes an opportunity for manufacturers to become more agile and responsive to changes in demand. The ability to quickly pivot operations is becoming increasingly important as global markets continue to evolve rapidly. By leveraging the power of automation, companies can remain competitive while meeting customer needs with ease.

Conclusion

In conclusion, it is evident that automation has brought about significant changes in the manufacturing industry. With the integration of advanced technology and automated systems, manufacturers can achieve increased efficiency in production processes. The use of robotics and artificial intelligence (AI) has led to reduced labor costs while improving quality and safety measures.

Furthermore, shorter lead times have been achieved due to the speed at which machines operate compared to human labor. As a result, productivity levels have risen exponentially, allowing for greater flexibility in meeting customer demands.

Automation provides an opportunity for manufacturers to remain competitive in today’s fast-paced business environment. As they say, ‘time is money,’ and with automation providing faster turnaround times, businesses can increase their profits by keeping up with market trends.

It is therefore imperative that companies embrace these technological advancements as they bring numerous benefits. In doing so, they will not only improve their operational efficiencies but also enhance customer satisfaction through timely delivery of products and services.