Comparison Between Gear Milling and Gear Hobbing

Gear is an essential element for rotating machines, with teeth fit together with an additional toothed component to transfer torque. Here we contrast as well as present 2 equipment production approaches- gear milling vs gear hobbing, what are the differences between them?

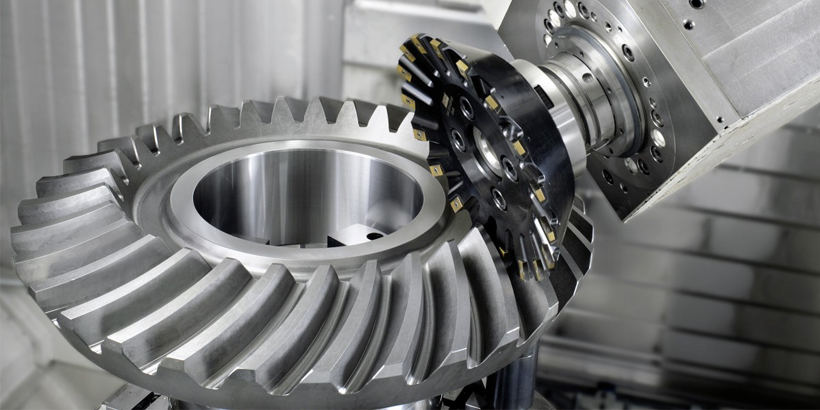

What is Gear Milling?

Gear milling is a common CNC milling operation as well as a gear-cutting procedure of creating a gear. It can be run either after or instead of creating processes including spreading, building, and squeezing out. Gears are typically made from metal, plastic, as well as wood. Lots of steel as well as plastic gears made by die-casting, injection molding, or additive production may not need reducing. For coarse-pitch gears, the generative gear milling modern technology can improve performance, expand the pitch capacity of the maker, decrease cutter expense, and might lower the machining times.

Cutter use in Gear Milling?

The gear can be reduced on a milling machine or jig grinder making use of a gear cutter and indexing head or rotary table, the amount of gear cutter is identified by the tooth matter of the gear called for. Different sorts of cutters can be made use of for generating gears, for example, the shelf shaper, with six to twelve teeth, straight as well as relocate an instructions tangent to the gear. The cutter needs to move back to the beginning position for the brand-new round cut.

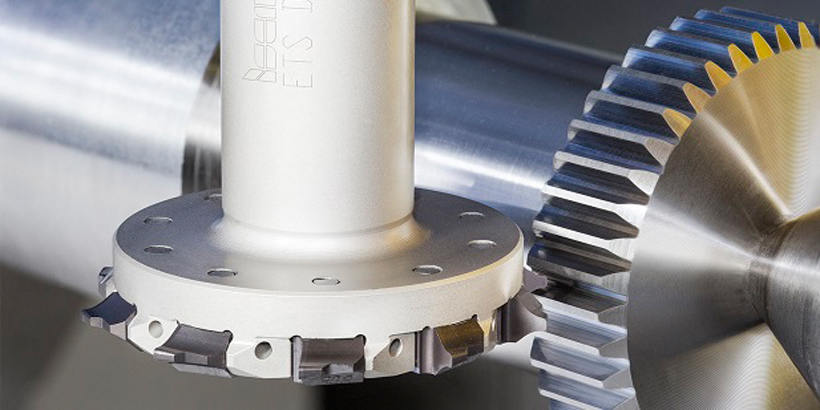

What is Gear Hobbing?

Gear hobbing is also a gear manufacturing technique to cut teeth right into the empty with a hob like an index hob as well as a master hob on CNC gear hobbing machines. The hob and gear empty rotate at the same time in a mesh and cut the teeth by continuous cut, the revolving hob is fed internally up until attaining proper deepness, after that work for the whole gear. Gear hobbing is a terrific selection for a tool to high quantity manufacturing runs. The hobbing features gears consisting of straight, helical, straight bevel, face, crowned, worm, and chamfering.

Distinction In Between Gear Milling and Gear Hobbing

Exactly how to separate gear hobbing and also gear milling?

Cutter

Gear milling uses a turning form cutter, when each tooth area is cut, the cutter will return to the starting factor and gear blanks are indexed for following cutting procedure; gear hobbing makes use of a helical hob cutter, the workpiece, and also the hob are both turning continuously when the hob is fed across the face size of the space.

Price of tool

Typically, the equipment milling reducing tool is less expensive than that of hobbing, however, the productivity of gear hobbing might be greater.

The variety of teeth cut in one time

Each cutter in gear milling is developed to cut a series of tooth numbers, while on duty hobbing, both the hob and gear empty rotate constantly as in 2 types of equipment meshing up until all teeth are reduced.

The means gear teeth are generated

In gear milling, a single tooth spacing or space in between gear teeth will certainly be produced by a rotating multi-edge cutter at a time, the cross-section of produced teeth is similar to that of the cutter. In gear hobbing, the gear teeth are gradually produced by a series of cuts with a hob. The hob reduces several voids concurrently.

Application

Gear hobbing is more frequently utilized for high production runs, and also gear milling is a low manufacturing procedure.

Others

- Equipment milling calls for deburring

- When other generating processes are unavailable, Gear milling is usually used.

Summarize

Gear milling is a usual CNC milling procedure as well as a gear-cutting process of producing equipment. The gear can be reduced on a milling machine or jig mill making use of a gear cutter and also indexing head or rotating table, the amount of gear cutter is determined by the tooth count of the gear required. Gear hobbing is likewise an equipment production method to reduce teeth right into the empty with a hob like an index hob and also master hob on CNC gear hobbing machines. In gear milling, a solitary tooth spacing or gap in between equipment teeth will certainly be developed by a rotating multi-edge cutter at a time, the cross-section of generated teeth is similar to that of the cutter.