Firmness Tests: Brinell, Rockwell, and also Vickers

There are numerous testing approaches for the firmness dimensions, such as Rockwell, Brinell, and also Vickers, which result in various expressions in firmness. You can also utilize the firmness conversion calculator for steels (ASTM E140-97). Additionally, introducing the distinction between Rockwell as well as Brinell firmness test.

What is the Firmness of a Material?

The material firmness is among the homes of a material, describes the stiffness or resistance to plastic deformation by penetration as well as imprint, flexing, scraping, machining, wear, generating, abrasion or cutting. Firmness permits the steel to resist being permanently deformed when a ton is applied. The more challenging the product is, the better the resistance it has to deformation, which indicates the much less most likely it is to warp.

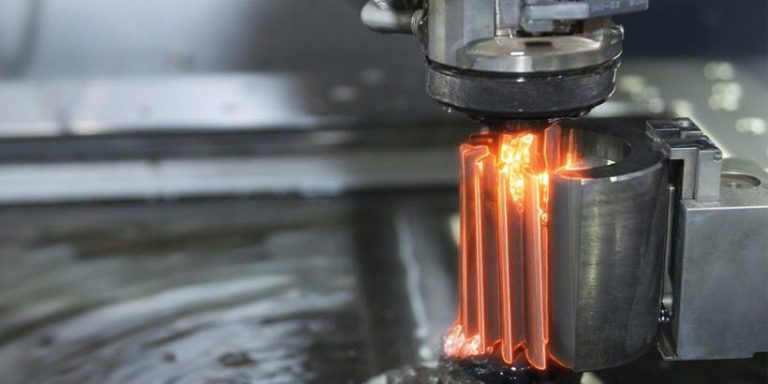

Because of the multiplicity of firmness interpretations and also gauging tools, the solidity is most likely to be a composite residential or commercial property of a material, reflects yield toughness, tensile strength, modulus of flexibility, and also even more, while not a solitary feature. When choosing a material or reducing device to generate CNC machined parts, firmness should be thought about.

Distinction In Between Rockwell and Brinell Firmness Examination

What is the Rockwell firmness examination? The Rockwell firmness test is a firmness measuring technique making use of Rockwell range to determine the depth of infiltration of an indenter under a huge load externally. Rockwell range has different ranges denoted by a solitary letter. The greater the number in the ranges suggests the harder is the material.

What is the Brinell Firmness Examination? The Brinell firmness examination is the method determining firmness through measuring the size of the impression left by an indenter or various other materials of a defined size, under a certain lot right into the surface.

The Rockwell technique is the most frequently used and also flexible hardness test. It does not need any material prep work and also additional devices, easy to check out, and additionally quicker and also cheaper than the Brinell as well as Vickers examinations.

Brinell, Rockwell, as well as Vickers Firmness Conversion Chart/Table

The firmness conversion table provides data in Rockwell (A, B, C, D, E, F), Rockwell Superficial, Brinell, Vickers, Shore, and Approximate Tensile toughness. You can convert firmness from HRB to HRC, HB to HRC, HB to HV, or other forms.