Guide to CNC Machining HDPE

CNC HDPE machining has lots of obstacles however plays an irreplaceable duty in specific, detailed components manufacturing, prior to choosing a material for your item or beginning manufacturing, find out about HDPE properties and also usages, High-density polyethylene interpretation, along with just how to CNC machine HDPE.

What is HDPE?

High-density polyethylene (HDPE), also called polyethylene high-density (PEHD), is a thermoplastic polymer that additionally can be called “alkaline” or “polythene” when made use of for HDPE pipes, normally the white or black solid product utilized in HDPE machining. As the name suggests, HDPE has a partially greater thickness than that of low-density polyethylene (LDPE), and also stronger intermolecular forces and also tensile toughness, which provides it greater particular toughness. HDPE components are cost-efficient options for several uses as a result of their affordability as well as toughness.

High-Density Polyethylene Residences

The high strength-to-density proportion is the amazing feature of HDPE, its physical buildings will vary relying on the molding procedure that is made use of to make an HDPE component. Check out the usual HDPE material properties below.

Thermophysical Characteristics of HDPE (High Thickness Polyethylene)

- Density of HDPE: 0.955– 0.961 g/ml.

- The melting point of HDPE: 126– 135 ℃.

- Thermal conductivity of HDPE: 0.35– 0.49 W/mK.

- The crystallinity of HDPE: 60%.

- The temperature level of condensation: 111.9 ℃.

- Specific Heat Capability of HDPE: 1330 to 2400 J/kg-K.

- Coefficient of Thermal Expansion (x 10-5): 12.5– 18.0 cm/( cm ℃).

- Warmth Deflection Temperature Level (0.5 MPa): 64– 77 ℃.

- Coast Firmness (D Scale): 55– 67.

Mechanical Features of HDPE (High-Density Polyethylene)

- Tensile stamina of HDPE (Return at 23 ℃): 23.0– 29.5 MPa.

- Tensile stamina of HDPE (Break at 23 ℃): 30.5– 33 MPa.

- Prolongation of HDPE (Yield): 9%– 18%.

- Elongation of HDPE (Break): 600%– 1350%.

- Tensile Modulus of HDPE (23 ℃): 900– 1550 MPa.

- Flexural Modulus of HDPE: 970- 1380 MPa.

Other Attributes or Residences of HDPE

- High strength-to-density ratio.

- Resistant to lots of various solvents.

- Low wetness absorption price.

- Excellent chemical as well as rust resistance.

- Greater impact resistance and tensile strength than LDPE.

What is HDPE Plastic Utilized for?

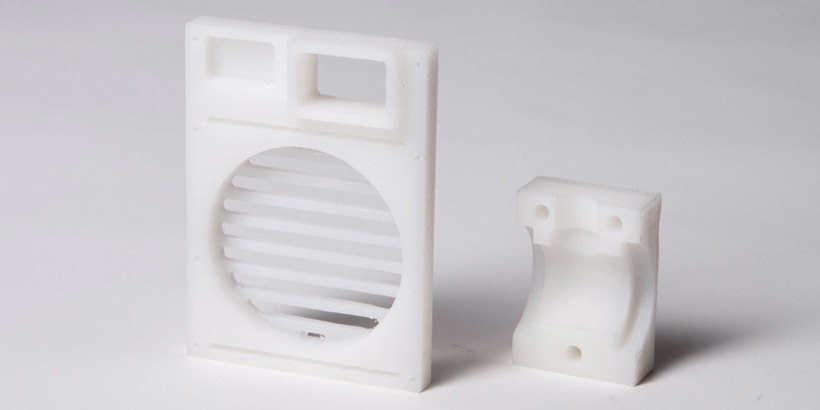

High-density polyethylene items are extensively utilized in a range of markets because of their safety, excellent corrosion-resistant efficiency, and also recyclability, including however not restricted to complying with applications. CNC machined components of HDPE can get to limited resistance and high precision to be used in a particular location. What is the usual HDPE plastic material made use of?

- Medical: disposable suits; non-woven HDPE textile.

- Building: different kinds of HDPE pipes.

- Chemical: chemical containers, piping.

- Food containers: risk-free and will certainly not send any chemicals right into beverages and also foods.

- Home appliances, kitchenware, various other household short articles: great strength and also rust resistance making it a suitable choice for waste bins, laundry cleaning agent containers, reducing boards, strong containers as well as even more.

- Electrical: coax cable inner insulator, conduit guard for electrical or communications wires.

- Car: gas storage tanks.

- Toys as well as playground equipment.

- Others: blown-film shopping bags with handles, HDPE jerrycans, ropes made from HDPE fibers, collapsible chairs and also tables, plastic bags, 3D printer filament, microwave telescope windows, etc.

HDPE CNC Machining Tips

Polyethylene is offered in sheets, rods, and special forms, making it a wonderful CNC machining product to be reduced on a turret or mill. CNC machining services have established an economical and also dependable way to make complicated and also exact parts for vital industry and approached a large range of plastic materials together with its growth. Machining polymers is different from the steel construction procedure, so it’s crucial to find out about the make-up, homes, and structure of HDPE prior to you machine it. How to make HDPE? Here are some details or tips.

HDPE is not an easy-to-machine material, the CNC milling procedure is advised and also high milling rates are needed. For the cutting device, end mill single or double flute bits can be thought about.

To avoid surface splits caused by heat generated during reducing and contortion due to the inner tension, annealing is an effective approach, to attain higher quality accuracy machining of HDPE.

During the machining procedure, you require to avoid the cutting chips from blocking your gadget. Water-soluble coolants can get rid of the chips as well as also keep good surface finishes as well as close resistances at the same time, another advantage of coolant is expanding the tool life, however, bear in mind HDPE has a very reduced CTLE.

Wish to find a plastic machining professional? DEK is constantly refining HDPE and other plastic components to client specs, drawings, or examples, our CNC device as well as tools cater for details engineering plastic materials with versatile milling, transforming, or machining services.