Guide to Engine Lathe

Lathe equipment is a machine tool used to produce turned elements with the desired shape and size. Usual types of lathes consisting of engine lathe, speed lathe, turret lathe, bench lathe, tool room lathe, wood lathe, CNC lathe, as well as a unique lathe. In this post, follow us to recognize what is engine lathe and also how does it function, in addition to the main parts of the engine lathe machine and also their usages.

What is an Engine Lathe?

Engine lathe is the most common kind of lathe device for general-purpose metal cutting. In earlier days, this type of lathe was originally established for machine engine obstructs and also driven by the steam engine and also for this reason it was called engine lathe.

Early engine lathes typically have coneheads with a spindle connected to them, a cone pulley-block created to approve a level belt, several spindle rates can be gotten by moving the level belt to various steps on the cone sheave. The contemporary engine lathes powered by small motors are a lot smaller sized as well as can be mounted on a regular workbench, but they are more effective than initial engine lathe machines. And also engine lathes today are typically outfitted with Computer system Numerical Control, enabling them to perform complicated CNC turning or machining works with less manual operations.

How Does it work?

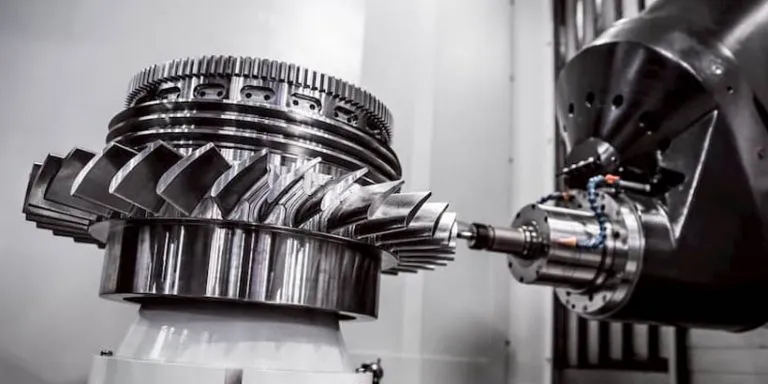

The engine lathe is usually used to cut metal and also can develop different particular kinds. The metal workpiece is clamped by the facilities in the lathe and also turned, the equipment utilizes special cutting tools to create the preferred form. The engine lathe deals with the principle of the block being revolved against a cutting device. Notable functions of the engine lathe are gears, a tipped pulley, tailstock, and a carriage. The gears operate to power the transportation and also support the cutting tools. The tailstock assistance opening making within the spindle. The tipped pulley block runs at multiple spindle speeds.

Parts of Engine Lathes and also Their Makes Use Of

Just how to run an engine lathe? Identify all the parts as well as mechanisms of the machine as well as their uses, you can operate the device to finish a specific job.

- The standard part of the lathe is the headstock where all equipment selectors are located. There are rate selectors and feed selectors, the feed is identified by the equipment.

- One more primary part of the engine lathe is the carriage, which manages all your motion in longitude as well as back and forth in latitude. Engine lathe additionally has an emergency stop button, if you press it, it reduces all the power to the lathe. 4-jaw chucks and also 3-jaw chucks both can be used on the engine lathe device.

- There is additionally a tailstock that is utilized for hole-making operations, drilling, reaming, touching, or simply holding the part between facilities or for maintaining lengthy shafts. In enhancement, the lead screw, as well as the feed screw, turn independently of each other on the device.

- The means is what everything remains on, the bed is where the means located, ways need to be cleaned and lubed in order to make them not rust.