Guide to Linishing

Numerous metal surface area completing solutions are attended to CNC machined components in DEK, here DEK will discuss what is linishing with its applications and benefits.

What is Linishing?

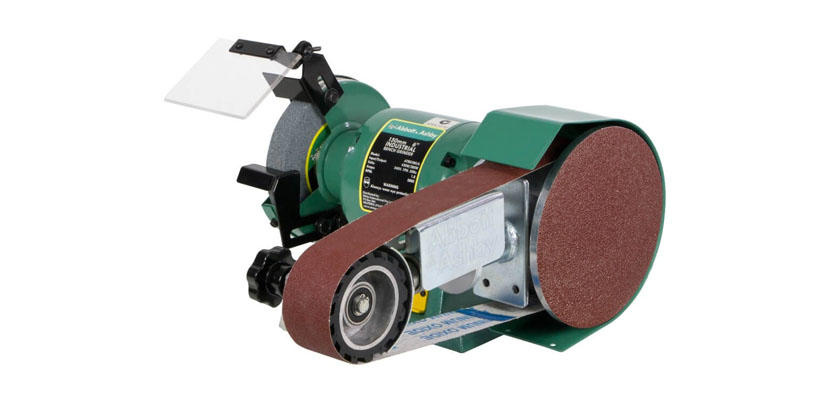

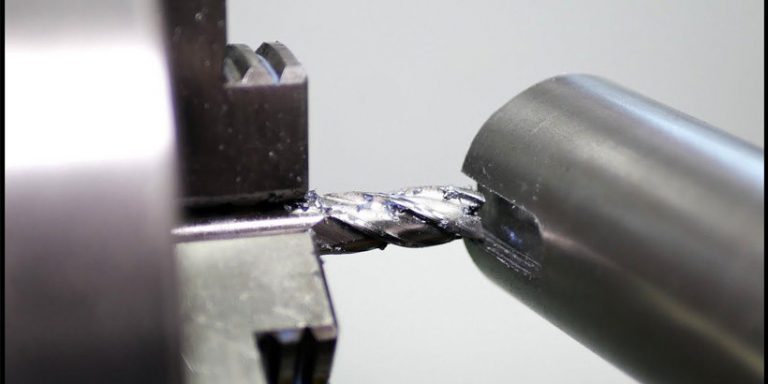

Linishing is a metal finishing method that doing grinding or belt sanding operation with a linisher or a linish grinder to flatten the surface of metal products. The approach can be used to improve total flatness to get a level and also surface, and also polish an object while collaborating with finer qualities of grindstone or fining sand belt. Linishing machines require to be geared up with special unpleasant belts or paper, which are perfect for both large metal items as well as little metal CNC components. Typical linishing tools including drum linishing machines, orbital linishing machines, and centerless linishing machines.

Use and Applications of Metal Linishing

- Shower room fittings, curtain poles, lights tools, chandelier parts.

- Furniture or wall cladding.

- Fashion jewellery and also consumer goods.

- Architectural industry. Smooth wavy metal building panel, create also cylindrical metal pipeline.

- Prep work of the ends of rubber extrusions.

- Automotive market and Vehicles. Vehicle parts finishing, fixing, motorbike deals with, bike components, car and motorbike exhaust systems.

- Remove joints and also seams from welded or fused metal objects.

- Clean away damage like pitting, corrosion, and also old coatings on the metal surface.

- Nautical fittings, machining store fittings, and so on.

Advantages of Linishing

- Improve stamina and also rust resistance.

- Appealing appearance as well as satiny, matte texture for aluminium parts.

- Suitable for various materials including carbon, stainless steel, aluminium, brass, titanium, etc.

- Easy and also flexible to finish. A hand linisher is applicable for small jobs.

- Repeatable for large volume production.