Aspects Impacting Surface Roughness and Exactly How to Enhance Surface Roughness

In the previous short article, we have reviewed the surface finish, the surface roughness as one of its features, it can be used to examine the high quality of machines as well as mechanical parts. Here we’ll present the variables influencing surface roughness and exactly how to enhance roughness.

What is Surface Roughness?

Surface roughness, usually reduced to roughness, which is defined as the shorter frequency of actual surface areas about the troughs, is quantified by the variances towards the regular vector of a real surface from its excellent kind. If these variances are large, the surface is rough; if they are little, the surface area is smooth. It is a vital index to tell whether a machined part is qualified or not. It influences the wear resistance, top quality, movement accuracy and life span of the parts in the process of usage. It’s significant to get suitable surface roughness in the CNC machining process.

The Factors Affecting Surface Roughness

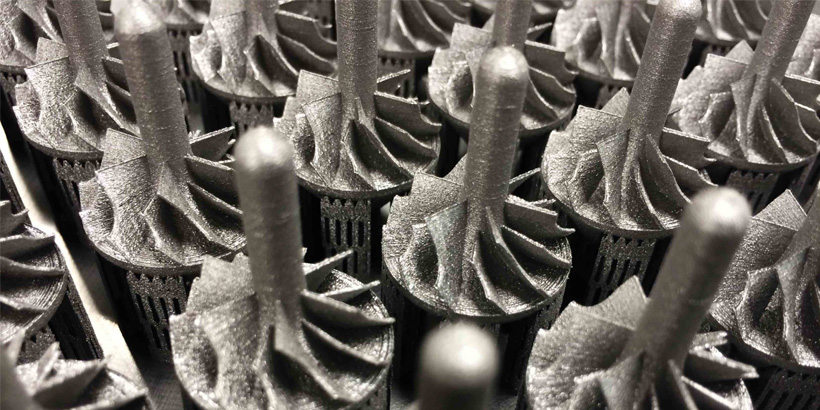

Grinding

It can acquire high machining accuracy and surface area roughness. When grinding, many of the components are squeezed out. In the plastic deformation procedure, the side of rough particles will certainly generate plastic warmth circulation, draw a small roughness on the components, and the high temperature will further grow the surface roughness.

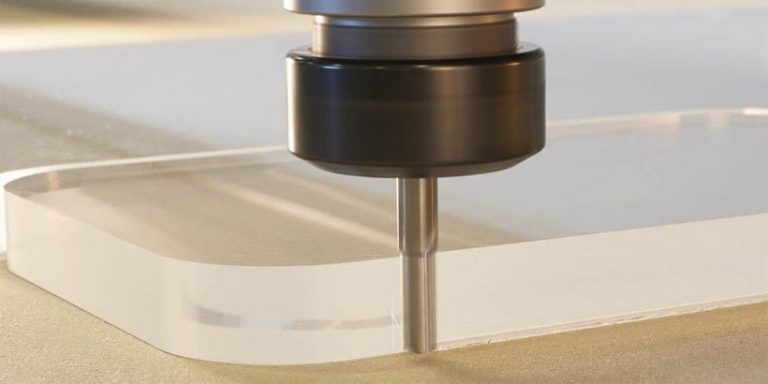

Cutting

When a cutting tool is utilized to cut a workpiece, there will be a residual cutting face on the surface, with mini geometric error, feed rate, main/auxiliary deflection angle as well as the radius of the tooltip arc, which will certainly influence the dimension of the recurring face. Adjust the feed rate and angle in the machining procedure can reduce the contortion and cut location of the part. On top of that, the lube and cutters selected should conform to the qualities of the material, reduce the plastic deformation, and hinder the development of device burr and scale. It is additionally a reliable step to lower the surface roughness by raising the rake angle of the device to lower plastic deformation.

Cutting parameters

- Cutting speed: When reducing plastic materials, when the reducing speed is less than 5 m/ minutes or more than 100 m/ min, it is not easy to create chip augmentation, which is beneficial to minimize the Ra value of roughness. When the cutting rate V is 20-25 M/ min and also the reducing temperature is about 300 ° C, the friction coefficient between the chip and the front face of the device is the largest, and the height of the chip increase is the largest, which raises the Ra value.

- Feed rate: decrease the feed price, the elevation of the recurring area of the machined surface area becomes smaller, which is beneficial to lower the Ra value of the roughness.

How to Enhance Surface Roughness

In the machining procedure of mechanical parts, the following methods can boost the surface roughness of the parts.

- Cutting condition: suitably reduce the amount of surface machining. Reducing plastic products with the high reducing rate; minimizing feed rate; using high efficiency reducing fluid; enhancing the kinematic accuracy of equipment devices, boosting the rigidity of process system; making use of ultrasonic resonance cutting, and so on.

- Select the geometric parameters of the tool: appropriately decrease the deflection angle of both and increase the span of the arc of the tooltip, as well as if necessary, grind the polishing edge. It makes the cut come to be much easier and lower surface area roughness. Select the tool product with tiny fondness with the work surface; carry out oxygen and also nitriding therapy on the tool; limit the wear quantity on the complementary blade; pick the fine-grained concrete carbide as the tool, and so on.

- Control the vibration of the machine tool: begin with decreasing the rubbing and also extrusion in between the tool as well as the workpiece, develop the tool edge, add cutting liquid, and also effectively warm treat some workpiece materials with great durability.

- Select a reasonable processing technology: in the process of accurately machined parts processing, machining technology is additionally really essential. If the process is unreasonable, it may impact the processing top quality as well as manufacturing performance. Lots of precision machined components require coating after rough machining.

- A different selection of raw materials: mechanical equipment parts are composed of many different basic materials. According to the different density of resources, the choice of reducing tools and equipment tools in the handling is straightly related to the surface roughness. The distribution of carbides in alloy aspects need to be uniform and great; the easy cutting steel needs to include aspects such as sulfur, lead, and so on; the workpiece should be toughened up to enhance solidity and minimize plasticity; the fragment dimension of graphite in cast iron need to be reduced.