Guide to Quality Control for CNC Machining Process and Products

Regardless of which market, item top quality is essential. In order to fulfill the expectations of customers, professional criteria, and also market law, DEK carries out quality assurance with different measuring tools and tools to examine the CNC machined parts created in our factory.

Why Quality control is necessary?

Quality control is an overall examination of items as well as manufacturing procedures, in CNC machining, quality control is essential to make sure the items manufactured to comply with the standard and also needs of the venture, sector, and clients. In addition, appropriate quality assurance of CNC parts will stay clear of faulty items, minimize dangers, make certain the dimensional accuracy as well as quality, preserve the resource, minimize price, and enhance effectiveness. It’s good for both customers and also manufacturers.

As a result, a reliable quality control system must be developed beginning with specifying and developing the high-quality requirement of each part. Specialist quality assurance and also assessment work is also required.

5 Tips for Quality Control for CNC Machining Process and Products

DEK is focusing on CNC machined parts quality control for each project, validating each client gets the desired product.

Discover the industry background

Based upon the different requirements in numerous sectors, when we obtained an order, apart from focusing on style illustrations, we also need to understand the market background. As an example, clinical and also military components typically need to come in outstanding accuracy, outright safety, exceptionally high quality, and also tight resistance, possibly need to hold up against severe conditions. DEK concentrates on custom-made CNC machined parts in a wide range of vital markets, like clinical, food handling and packaging, electronic devices, vehicle, aerospace, military, marine, equipment device, state-of-the-art, and also a lot more.

Comprehend the design of the item

When customers send out a CAD drawing of the end product, our engineers and designers will assess the style in detail as well as very carefully, understand the product specs and needs of clients, check out each information prior to manufacturing. We’ll use one of the most cost-efficient option to machine your component, manage the elements throughout the CNC machining procedure, and ensure attain the demands.

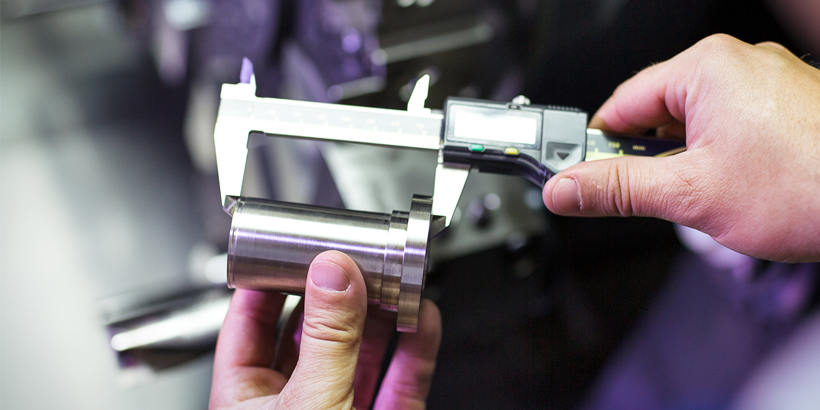

Have a look at parts with accurate determining device

Specialist measuring equipment operators at DEK will certainly function with the final components after machining. Assessors might do inspections on the component either it’s on the maker or after removing it from the manufacturer.

Do examination when the component is running

Occasionally, we need to carry out a top quality inspection when the machined component is running, so regarding identify troubles early and also revamp the part prior to completing. There are some operations that can be done to readjust the device for holding tighter resistance, such as adjusting the tool offsets to leave a little excess stock, permit the device to machine the work surface, gauge what the tool has actually done, and also more. This is especially suitable for freshly developed items.

Connect with clients

Whether in the production procedure or after sending a sample, it’s effective to interact with clients timely. Customers as well as clients will certainly have clear demands on the product spec and also feature when getting questions from clients, we will certainly get in touch with them quickly and also offer a totally free quotation as soon as possible, if there is something not right, we’ll adjust the service instantly. For special requirements, please inform us ahead of time.

Summary

Quality control is an overall inspection of items and manufacturing procedures, in CNC machining, high-quality control is necessary to make certain the items produced adjust to the standard as well as needs of the venture, industry, and consumers. In addition, proper top quality control of CNC components will avoid faulty products, reduce threats, guarantee dimensional accuracy as well as top quality, conserve the resource, minimize price, and also boost effectiveness.

Military, as well as clinical components typically, should come in impressive precision, outright safety and security, superb high quality, and also limited resistance, perhaps need to hold up against extreme conditions. Assessors might do inspections on the part either it’s on the machine or after removing it from the manufacturer. Often, we need to carry out a top quality inspection when the machined part is running, so as to recognize issues early and rework the component prior to completing.