Overview of CNC Milling

As a common machining process, CNC milling parts are common in our daily life and in lots of industries. What’s the CNC milling process and why utilize it? Right here DEK offers the CNC milling pros & cons, benefits, applications, materials, kinds, interpretation and more.

What is CNC Milling?

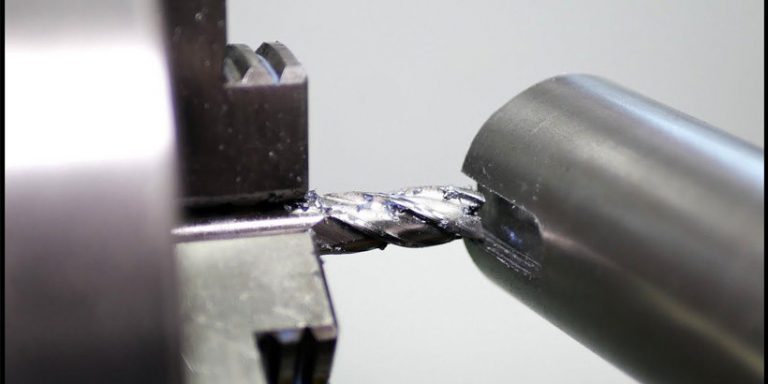

CNC milling is a machining approach that makes use of the multi-point rotary milling cutter to get rid of materials from the work surface making feed movement on the CNC milling machine, to produce a wide selection of features or parts. Milling is typically made use of to create numerous flat surface areas, grooves, ports, gears, racks and also various other profiles. DEK CNC milling services can give top-grade economical custom crushed components for lockset, vehicle, food machinery, army & protection sector, medical tools, house appliance, etc.

CNC Milling Pros & Cons

Pros of CNC Milling

- Repeatability, the exact same products with precise specifications can be generated as initial design numerous times.

- Computerized numerically control to validate the precision and also the accuracy of end products.

- Automation reduces the variety of operators and also labour costs yet keeps the top quality.

- Makes it possible for complex layout, requirements, tasks, and also geometries.

- Excellent flexibility and adaptability of CNC milling parts processing.

- The milling cutter is a sort of multi-tooth device, each tooth on the milling cutter joins the job intermittently, which causes excellent cooling conditions for the cutting tool, high cutter resilience enhanced cutting speed as well as high efficiency.

- Can produce a wider variety of products than the planer, so it can almost replace the planer.

- CNC milling is excellent for rapid prototyping as well as mass production.

- Thousands of milling components manufacturing can be performed in a short time.

Cons of CNC Milling

- The CNC milling equipment, as well as the configuration, are extra pricey than hand-operated tools.

- The employees who run milling devices need proper training.

- It takes an amount of time for layout as well as programming, not so affordable for small amounts of products.

CNC Milling Materials

- Plastics consisting of POM, ABS, PVC, Nylon, PEEK, etc.

- Metals. One of the most usual CNC milling materials kinds, including aluminium, steel, brass, stainless steel, titanium, copper, bronze, zinc, magnesium, and so on

– CNC milling aluminium components: simple to machine, financial, corrosion-resistant.

– CNC milling stainless-steel components: can be heat-treated, deterioration resistance.

– CNC milling brass components: easy and cost-effective, steady, reduced rubbing coefficient and high rust resistance. - Ceramics, glass, rubber, wood, foams, and so on.

CNC Milling Kinds

- Gang Milling

- FormMilling

- ProfileMilling

- End Milling

- Saw Milling

- Gear Milling

- Helical Milling

- Cam Milling

- ThreadMilling

- Plain Milling

- Face Milling

- Side Milling

- Straddle Milling

- Angular Milling

- Keyways, Grooves, and Slot Milling

CNC Milling Applications

CNC Milling is just one of the most typically utilized machining procedures, including plain milling and also contour milling, which can process as well as tap components. CNC milling is applicable to a diverse range of objects.

- Angled parts. The parts whose angle in between the machining surface as well as the straight surface area changes continually are called variable angle components. It is better to make use of the five-axis or four-axis regulated milling maker to refine the parts with a variable angle.

- Curved parts. The machining surface area of curved parts is constantly in factor contact with the milling cutter, which is typically defined by a 3-axis CNC milling machine.

- Flat parts. Each surface area is a plane or can be increased into a plane, the vast bulk of parts processed on CNC milling device are flat components, it’s also the easiest CNC milling things, which can be finished just by 2 coordinate linkages of three coordinate machines.

CNC milling services gives a huge variety of top-notch precision milling elements for automobile, aerospace and also aeroplane installations, health care, electronic devices, medical gadgets, surgical tools, consumer goods, design, etc.