Several Kinds Of CNC Milling Machines

A milling machine, also known as a mill, is a sort of equipment device used to process various surfaces and also profiles using rotating cutting tools. To match certain demands, there are a ton of different types of milling machines readily available to pick from on the market. In this article, we are mosting likely to learn about the category of milling machine as well as figure out the right alternative for the job.

Milling machines can be made use of to cut keyways, gears, ports, racks and other features, as well as do milling, boring, drilling, and a lot more procedures with numerous accessories as well as setups. Milling machines can generally be classified right into horizontal and vertical milling machine based on the axis of the machine spindle. These machines can also be divided into knee type milling machines, ram-type milling machines, bed-type milling machines, planer-type milling machines, etc. CNC milling machine is designed for the large batch production run of milling parts with high consistency.

Column and knee type milling machines

Column as well as the knee-type mill is a common kind of milling machine for basic purpose. Column, spindle, cutter, table, knee, base are the basic parts of the vertical and also horizontal kind mills. On column and also knee kind milling makers, a vertical column is connected to the bed that contains all gear drives which turn the knee as well as saddle, the knee is located on the base to make it possible for the component to go up as well as down.

- Universal milling machine: typically, a mill is called a global milling machine since it has both vertical and straight pin, with appropriate attachments and accessories, it can do anything you wish to. Doing the job of an ordinary milling machine, it can therefore be made use of for a nearly limitless range of various other procedures in the manufacture of equipment and tools.

- Horizontal milling machine: attributes a spindle flat oriented. The cutting device mounted on the pin can remove the product from the repaired block uniquely. The spindle sleeve can be fed by hand, the worktable can be up and down and also flat by hand-fed and vertically lifted, the main drive, as well as feed, embrace an equipment speed change system, with a large rate variety. Horizontal milling machines often have much shorter as well as thicker cutters than vertical machines.

- Vertical milling machine: utilizes a pin with an upright orientation. The pin can rotate the milling or hold cutter against the stationary workpiece, also can go up or down. Vertical milling machines are a sort of column and also knee devices. The upright milling machine is suitable for machining larger planes as well as machining grooves as well as step aeroplanes with numerous milling cutters with shank. The performance of the upright milling machine is more than that of the straight milling machine. All sort of cylindrical milling cutters, creating milling cutters, end milling cutters, as well as angle milling cutters can be installed directly or through accessories. It is commonly made use of for machining plane, inclined plane, groove as well as a hole of various parts, as well as optimal processing tools for equipment manufacturing, mold, tool, meter, vehicle, motorcycle, and other sectors.

Special kind milling machines

- Planer type milling machine: the cross-rail lugging a rigidly sustained cutting tool, the table has a reasonably slow feed needed for milling. This type of mill is perfect for machining wide surface areas on work surfaces.

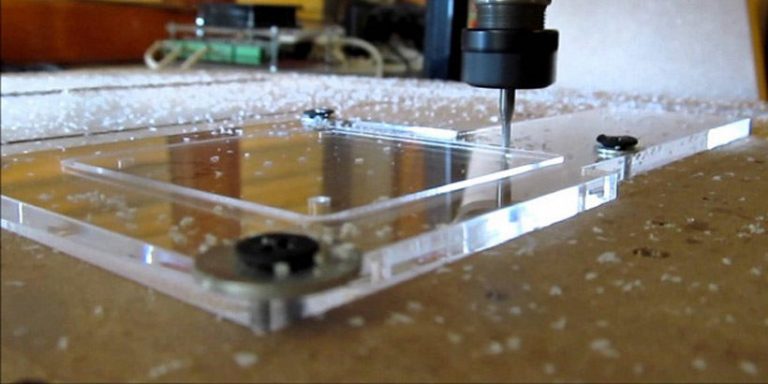

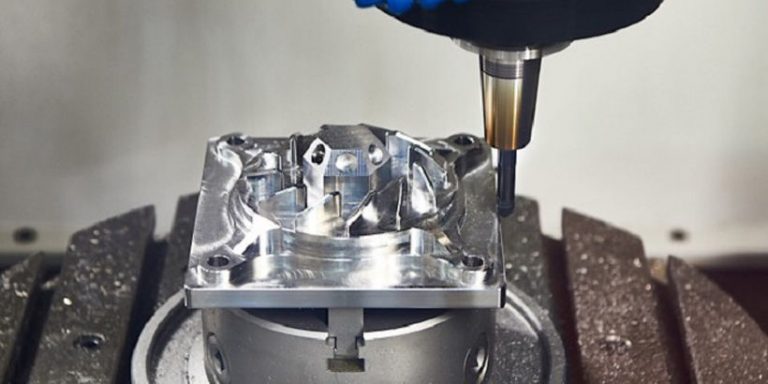

- CNC milling machine: refers to the milling machines that use computerized controls to execute specific movements according to the set instructions, to progressively remove materials from the block as well as create the preferred component the same as the design.

- Bed kind milling machine: created with a gliding table which is placed on the machine bed, the cutting deepness can be obtained as the demand based on adjusting the pin. This sort of milling machine is suitable for continual milling applications.

- Ram type milling machine: identified by a spindle mounted to a movable housing on the column, permits operators to place the cutter in a horizontal aeroplane. Universal ram-type milling equipment and swivel cutter head ram-type milling equipment are the prominent alternatives among this category.

- Gantry milling machine: a type of milling machine with a gantry framework and also a horizontal long bed. On the gantry milling device, the component can be processed all at once with numerous milling cutters, which likewise delivers high machining precision as well as manufacturing performance.