Tips for CNC Milling Machining Titanium Alloy

The special properties of titanium alloy make it an eye-catching material for metalworking to produce items for lots of vital industries, likewise impact its machinability in CNC machining, so in this write-up, DEK will certainly go over the tips as well as the method of CNC milling titanium and titanium alloy.

What Conditions Does CNC Milling Titanium Requirement?

Several difficulties, as well as problems in traditional titanium milling and processing, are not inevitable, the key point is to conquer the impact from the homes of the metal.

- Compared to various other metal, titanium machining is not only more required but also has even more limitations. In the machine shop, according to the needs of titanium machining, pick the right tool and utilize it appropriately, maximize the machine tool as well as an arrangement to the most effective problem, to obtain processing with high performance.

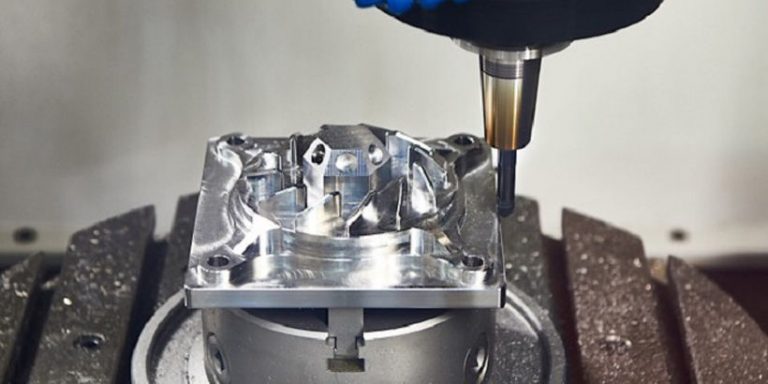

- From titanium properties, it has an exceptional strength-weight proportion and also density is 60% of that of steel, lower coefficient of flexibility than steel, greater hardness, better deflection, higher deterioration resistance and reduced thermal conductivity. All of these make it produce greater as well as more concentrated cutting force in the machining process, it’s also easy to reasons vibration and also milling babble, if the material responds with reducing tools, the crater wear will certainly be exacerbated. Furthermore, as a result of the inadequate thermal conductivity, the reducing warmth might concentrate in the reducing area, so selecting a titanium cutting device with high thermal firmness is necessary.

- In the actual titanium alloy milling procedure, it’s hard to fulfil all the demands, because the ideal problems and also machining stability is not always readily available, as a matter of fact, the form or geometry of great deals of titanium machined components is intricate as well as customized, it may have deep or great tooth cavities, slim walls, bevels, contours, slim brackets or other functions, to device titanium with these details, big looming milling cutters with little sizes need to be used, yet it will certainly influence the security of tools, other prospective issues are additionally likely to happen in the cutting process.

- Titanium alloy is a difficult-to-process material for several workshops, nevertheless, lots of problems can be fixed with modern-day machining services as well as tools. Compared with various other steels, titanium CNC milling is a relative brand-new modern technology as well as not that knowledgeable, in addition, the titanium items typically used in aerospace and military devices, raises the requirements of titanium items, so it seems to be more difficult to machine titanium. Generally, the device and speed made use of in machining cast iron or low alloy steel is not suitable for machining titanium.

- Also, make contrast with stainless steel CNC machining, titanium processing is still more challenging. Different cutting rate, feed price and preventative measures are needed to be taken to refine titanium, as long as there are stable workpiece and also machine tool, best cutting device and setup, firm clamping, suitable reducing pressure, good working condition, and ISO50 spindle with brief tool overhang is furnished, all troubles will certainly be resolved.