Guide to 316 Stainless Steel

As a popular stainless-steel grade, 316 stainless-steel has lots of variations like L, F, H, and N, which come in subtle distinctions. Right here we’ll talk about a typical type 316L, what’s the distinction between 316 and also 316L stainless steel, plus alloy 316 meaning, composition, residential properties, as well as applications.

What is 316 Stainless-steel?

Stainless-steel 316, likewise known as UNS S31600, is mostly composed of Fe, 16-18.5% Cr, 10-14% Ni and 2-3% Mo, additionally includes <0.03% C, <2% Mn, <1% Si, <0.045% P, and <0.03% S, so it expressed as 0Cr17Ni12Mo2. Examine our international requirements conversion table for different representation approach for various metals.

Quality 316 is a preferred austenitic stainless steel alloy and also the 2nd most widely utilized grade after stainless steel 304. As a result of the addition of Mo, its deterioration resistance, resistance to acids, antacid, and chloride pitting are especially good. 316 stainless can withstand high temperature approximately 1200-1300 ℃, and also used in severe problems with excellent work solidifying efficiency( non-magnetic) as well as heat strength. When treated with cold-roll, it reveals great gloss and also a beautiful appearance.

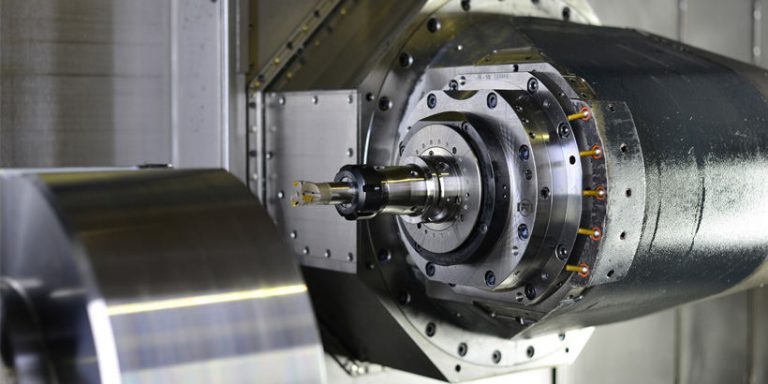

DEK concentrates on 316 stainless steel CNC machining as well as gives milling/turning/drilling services, as well as precision, machined elements for different stainless kinds.

316 Stainless Steel Properties

- Melting point: 2,500 ℉– 2,550 ℉( 1,371 ℃– 1,399 ℃).

- Thickness: 7.98 g/cm3.

- Tensile toughness (minutes): 515 MPa.

- Yield stamina (0.2% evidence, minutes): 205 MPa.

- Elastic Modulus: 193 GPa.

- High strength.

- Rust resistance.

- Resistance to matching and also gap deterioration in chloride settings.

- Outstanding forming as well as welding characteristics.

- Conveniently roll formed.

- Susceptible to stress and anxiety rust breaking over 60 ° C.

Applications of 316 Stainless-steel

Because of its exceptional deterioration resistance in atmospheric atmospheres and even more immune to corrosive media than 304, alloy 316 is commonly used to produce tools and components utilized in seawater (boat installations), chemical market (lab benches, containers), colour, paper production, manufacturing equipment of oxalic acid and plant food. It is generally considered the basic “aquatic grade stainless steel”, but it is not resistant to warm saltwater.

On top of that, photography devices, cooking devices, coastal facilities (coastal architectural panelling, railings & trim), woven or bonded displays for mining, quarrying & water filtration, ropes, CD rods, springs, screws, nuts outdoor electrical enclosures, medical and also pharmaceutical tools are possible stainless-steel 316 applications.

Distinction Between 316 and 316L Stainless-steel

Despite the fact that 316, as well as 316L, have a high resemblance, their prices are approximately the very same, we can likewise differentiate them in the structure, mechanical residential properties, and various other aspects.

Composition

The vital distinction between standard 316 stainless-steel and SS316L is the make-up, 316 contains even more molybdenum than 316L, which leads to enhanced resistance to matching and also hole corrosion and also far better security when subjected to high-chloride chemicals and acids. Additionally, 316L is the low-carbon variant of 316 due to the fact that it has a lower carbon content than 316, on the other hand, quality 316H is the greater carbon version. Kind 316 stainless steel includes up to 0.08% carbon while the maximum carbon content of kind 316L is 0.03%. The 316L will certainly additionally be softer than 316 as a result of the reduced carbon. For the percents of other aspects, 316 and also 316 have virtually no distinction.

Application

316L is a much better selection for the application or the construction procedure requires a great deal of welding due to the fact that the lower carbon material decreases unhealthy carbide precipitation. But 316 can be hardened to withstand weld decay. And, 316L is the main option for medical implants, instead of SS316.