Guide to Adjustment Device in CNC Machine

Device magazine, as well as the Automatic Tool Changer, are the most commonly utilized components in high-speed CNC vertical machining. When machining different materials, altering the machining procedures, or the device is damaged, the CNC cutting tool usually needs to be changed.

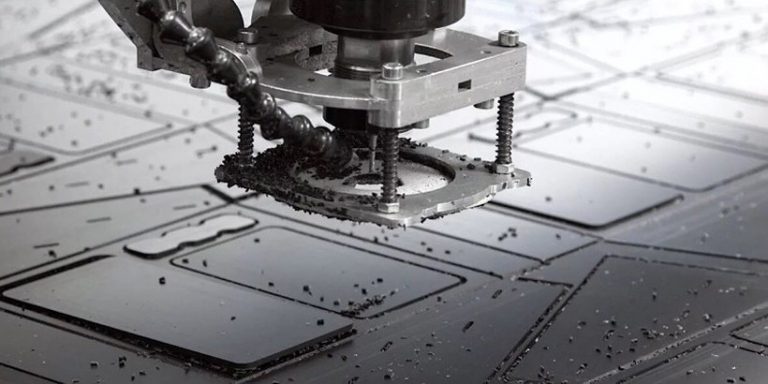

Exactly how Does a CNC Tool Changer Job

When the CNC machine is running, there is a sensor on the tool changer slide carousel that tells the device that the tool changer remains in its complete reach retracted park setting if the sensing unit does is not true throughout any kind of procedures of the machine, you’ll get a mistake in the device, the device changer is mosting likely to step forward and also hit the Z head, so when we are going to do a device change, the spindle will certainly relocate to the Z height for the tool change to go as well as occur via a pin alignment.

It requires to relate the spindle to ensure that the dogs are lined up with a slot in the tool changer to make sure that when the tool changer can be found in the clip, it will certainly engage in the groove of the flange of the device owner and also the drive dog on the pin will go inside of a little notch, after that the tool holder will be kept inside the device changer. When we’re at the Z elevation and we’re related and also the pin is locked in its orientation placement, after that the equipment will certainly require the device changer ahead in when the tool changer can be found in, there’s an additional limitation button that informs the machine controller that the tool changer is totally in the tool turn, so it waits on that limit button to be made prior to it will advance the cycle.

As soon as the device changer remains in the complete change position, we’re mosting likely to release the drawbar to allow go of the existing device, so when this occurs you’ll see the device adjustment or slide carousel get lowered simply a little and that’s the drawbar totally releasing the device. There’s a sensing unit on the drawbar piston to signal when the drawbar has totally launched, the device will not go on until that sensing unit is made. When that sensing unit is made then the z-axis will certainly go up to the changing height, once we finish that step, after that the signal will be sent out to the slide carousel to revolve to the tool pocket, the following tool is in.

When the spindle comes all the way down once again, you’ll see that it pre-loads the carousel simply a little while the pin seats totally on the following device and afterward as soon as that Z relocation is total after that the drawbar will certainly launch, and after that, the equipment will recognize that it has the following tool strongly held in the spindle and after that, it will certainly require the tool changer to pull back and then they will certainly wait to form the tool changer to completely withdraw and that retract park restrictions which to be made, so the equipment understands that the tool changer is completely out of the way, afterward, the tool adjustment cycle is total, the alignment device that locks the pin, as well as its alignment for the tool modification, will then release, we can take place to CNC machining.

How to Change Device in CNC Machine

In CNC programming, the tool change code is M06, which is the M-Code made use of to trigger the automated device modification along which T number is called on the program. When the controller checks out the T number with M06, it will certainly look at the tool publication for the T number specified as well as revolve, then bring the device right into the pin. Lots of lathes do not use M06 since the T address itself indexes the turret.

Device Change Procedure

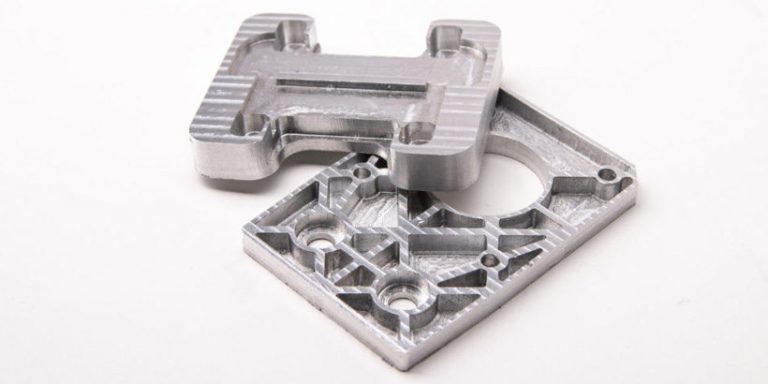

What is Device Offset? Tool offsets are the collection of values that move the facility factor of the cutter to the appropriate position for reducing the part using a particular device.

- Homing

- Measure tool offset with fixed device sensor

- Establish current X, Y offset

- Action existing Z countered with movable sensor

- Start spindle as well as begin cutting

- Pause to shut off the spindle

- Pause to transform the device

- Measure the second device offset

- Pause to turn on the spindle

- When cutting is finished, turn off the spindle