Guide to 360 Brass

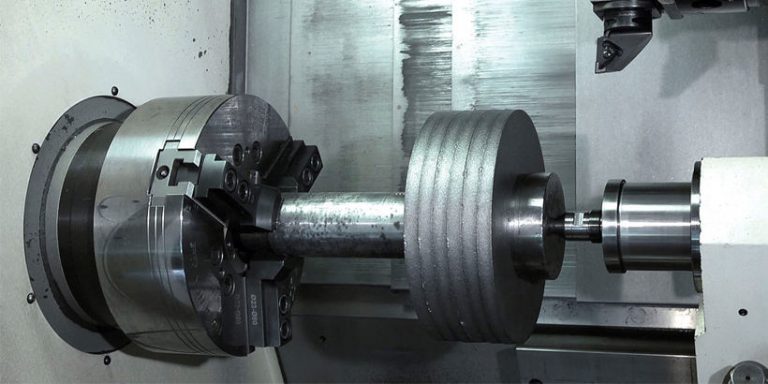

Brass is a preferred material for CNC lathe and also CNC milling components manufacturing, specifically the 360 brass, which is called free machining brass. What is 360 brass and also what is it used for? Here DEK will certainly begin with its make-up, introduce the brass 360 homes and distinction in between 260 and 360 brass.

What is 360 Brass?

360 Brass, also referred to as Alloy 360 or C36000, is a soft, pliable metal and also standard alloy mainly contains copper as well as zinc, added a small amount of lead and various other components. What is 360 brass made of? The chemical structure of brass 360 is 61.5% copper, 35.5% zinc, 3% lead, as much as 0.35% iron.

Brass 360 Properties

The material of specific metal aspects will certainly offer the product special qualities as well as mechanical residential properties. For instance, the 3% lead provides 360 brass with the highest degree of machinability of all copper alloys, make it simple to procedure in CNC brass machining.

- Free machining and cutting (minimal tool wear)

- Tensile Strength of 360 brass: 58,000 PSI

- Yield Strength of 360 brass: 45,000 PSI

- Elongation of 360 brass: 25%

- Rockwell Hardness of 360 brass: B78

- High strength and resistance to corrosion

- Suitable for polished surface finish

- Good hot forming properties

- Not ideal for cold forming, welding, soldering, and brazing

- Can be forged and annealed

- The high return value of scrap

360 Brass Utilizes and Applications

Based upon the performance as well as properties of brass 360, it can be used in the following applications.

- General screw machine.

- Pipes products, fittings, adapters, valve stems, and various screw machine parts.

- Gears, lock components, pipefittings, as well as ornamental applications.

- Industrial and also electronic markets.

- Hex studs, bolts, as well as nuts.

- Couplings, bushings, connectors, fittings, valve parts, pump shafts, brackets, and so on

- Electronic hardware and contacts.

- Musical instruments.

Distinction Between 260 and 360 Brass

- Chemical structure. Brass 260 is made up of 68.5– 71.5% copper, 28.5– 31.5% zinc, 0.07% max lead, 0.05% max iron, the content of copper is more than 360 copper, and the content of zinc and also lead are lower than 360.

- Mechanical properties.

| Brass Alloys | Brass 360 | Brass 260 |

| Tensile Strength | 58000 PSI | 61600 PSI |

| Yield Strength | 45000 PSI | 52200 PSI |

| Elongation | 25% | 23% |

| Rockwell Hardness | B78 | B77 |

- The 260 brass is not very simple to machine, while 360 brass has outstanding machinability.

- 260 brass offers wonderful formability as well as workability, alloy 360 is not suitable for forming operations.

- 360 brass is described as leaded brass, 260 is called cartridge brass.

- 260 brass is commonly made use of for ammo elements, builder’s hardware and also plumbing goods, and 360 brass is primarily utilized to manufacture screw machined parts.