Overview of Cast iron made use of for machining

DEK is mosting likely to describe just how to select the metal for your machining project, focusing on the properties, benefits and also downsides of the metals.

Ferrous metals refer to those including iron such as cast iron, steel, and so on. If strength is one of the most vital factors for your project, ferrous metals are your finest alternative.

Ductile Cast Iron ASTM 536

Normally, pliable cast iron is utilized for cast iron pipe, which is used for water and sewer lines. Ductile iron is a kind of metal that serves in a lot of auto parts, specifically, toughness ought to be far better than that of aluminium. It can additionally be used in commercial fields such as agricultural tractors, oil well pumps and Class 8 vehicles. Nodular actors iron is applicable for hubs and also structural components like device frames in the wind power market and benefits complicated and high loads and huge forms. Ductile cast iron has great resonance moistening, so it is much better than steel when it pertains to producing machine tools.

Pros

- Ductile cast iron can dissipate warmth well since of the graphite.

- Ductile cast iron has wonderful wear resistance.

- Ductile cast iron is stronger than grey actors iron. The tensile strength of ductile actors iron is between 60,000 psi and 120,000 psi, while the tensile strength of grey cast iron is from 20,000 to 60,000 psi.

- Ductile cast iron can be conveniently machined. Coolant is not called for, due to the fact that graphite is a natural lubricating substance.

Cons

- Ductile cast iron programs nodules.

- Ductile cast iron can make a mess due to the fact that of the graphite.

Grey cast iron (ASTM A247, ASTM A48 and SAE J431)

The graphite remains in the form of flakes in grey actors iron, which encourages creaking. For the flakes are stress risers. If your task affixes significance to sturdiness and also wear, grey actors iron may not be a great metal to select.

Pros

- Grey cast iron has great wear resistance.

- Grey cast iron doesn’t require coolant as the graphite and also can be conveniently machined.

- Grey cast iron relatively costs lower.

- Grey cast iron usually includes silicon, which has terrific corrosion resistance.

Cons

- Grey cast iron does not have an impact and also shock resistance.

- Gray cast iron can make a mess due to the fact that of the graphite.

- Grey cast iron can not be rolled, forged or extruded due to its tendency to fracture.

- Grey cast iron shows flake microstructure.

About DEK

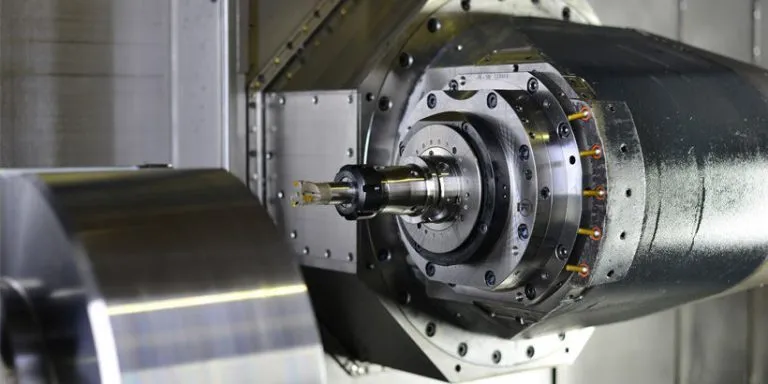

DEK, found in 2002, was a machining factory at the beginning. For decades, through continuous investment in equipment, and continuous investment in other companies, now DEK is a China leading full services company of CNC machining, precision machining, 3D printing, plastic injection moulding, which helps customers achieve their products from design to mass production.

If you need a prototype, medical equipment parts, precision aluminium parts, or any other plastic and metal parts, there is no better supplier than DEK. We have a variety of processing equipment and sophisticated testing equipment, enough to deal with any complex or tight tolerance products.