Guide to 4130 Alloy Steel

Steel is the architectural material of the building as well as the transport industry on the earth. Its alloy aspects give it numerous superb qualities and additionally obtain a selection of kinds. Based on the designation system stood for by AISI and SAE, we commonly use a four-digit number to call different alloy steels. What we’ll layout in this article is 4130 alloy steel, from its detailed make-up and construction qualities, to 4130 steel buildings as well as usages, along with AISI 4130 steel vs 4140.

What is 4130 Alloy Steel?

4130 steel (AISI/SAE 4130) is chromium-molybdenum steel with 1% molybdenum/chromium by mass with an included 0.30% carbon. The name of alloy steel are designated by AISI and SAE using a four-digit number, the first number shows the course of steel, including its significant alloying components, the 2nd figure reveals the loved one percentage of this alloying aspect and/or other crucial additional aspects and last 2 numbers suggest the carbon focus in 0.01% increments. 4130 Alloy steel is low-alloy steel that has good strength, sturdiness, weldability and also machinability, along with great climatic rust resistance.

When it comes to manufacturing as well as handling of 4130, AISI 4130 steel is weldable in all commercial methods, and also conveniently machined in its normalized/tempered condition, CNC machining services for 4140, 4130, A36, 1018 and also more steel alloys are offered at DEK. Creating of SAE 4130 grade can be carried out in the stiff condition, it can be annealed at 843 ° C. Forging of 4130 steel can be done at 954 to 1204 ° C. Hardening of AISI 4130 alloy steel can be performed with cold working or warmth treatment, the cool working can be done utilizing traditional methods and warm working can be done at 816 to 1093 ° C. And tempering of 4130 steel can be done at 399 to 566 ° C. The temperature for alloy 4130 heat therapy usually varying from 899 to 927 ° C.

Check out the break down of 4130 steel make-up:

- C (Carbon): 0.28%– 0.33%.

- Mn (Manganese): 0.40%– 0.60%.

- P (Phosphorus): 0.035% max.

- S (Sulfur): 0.040% max.

- Si (Silicon) 0.20%– 0.35%.

- Cr (Chromium): 0.80%– 1.10%.

- Mo (Molybdenum): 0.15%– 0.25%.

4130 Steel Properties

Physical Characteristics of AISI 4130 Steel.

- Density of 4130 Alloy Steel: 7.85 g/cm3 (0.284 lb/in ³).

- Thawing Point of Steel 4130: 1432 ° C( 2610 ° F).

Mechanical Features of AISI 4130 Steel.

- Brinell Solidity of 4130 Steel: 217.

- Rockwell B Firmness of 4130 Steel: 95.

- Rockwell C Firmness of 4130 Steel: 17.

- Vickers Firmness of 4130 Steel: 228.

- Ultimate Tensile Strength of 4130 Steel: 560 MPa (81200 psi).

- Return Tensile Stamina of 4130 Steel: 460 MPa (66700 psi).

- Modulus of elasticity: 190-210 Grade point average (27557-30457 ksi).

- Elongation at break (in 50 mm): 21.50%.

The applications of 4130 Steel

4130 alloy steel is referred to as its stamina when it is used for warm treatment, it executes best as structural steel, high strength and also reduced alloy product make it function well for welding, making and also cutting of aeroplane parts and also other markets. Steel 4130 likewise finds its usages as forgings in oil & gas areas, made as created shutoff bodies as well as pumps, along with car, farming and defence industries. Usual applications of 4130 steel including:

- Sphere and roller bearings.

- Gears for aerospace and other markets.

- Automotive components, lorry components and also rock crushing equipment.

- Architectural components like rounded tubes or bar stock.

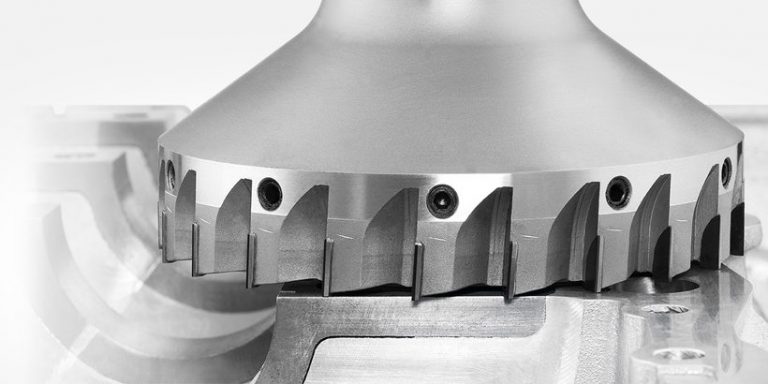

- Reducing devices like drills, faucets, grating cutters, etc.

- Resistance welding.

Distinction Between 4130 Steel and also 4140

4140 resembles 4130 alloy steel with the exception of the carbon content, which we can find from the last two figures, The “40” in 4140 stands for greater material of carbon than that in 4130, the distinction in make-up additionally makes their properties distinction. Below are the details.

Make-up

4130 consists of 0.28-0.33% Carbon and also 0.40-0.60% Manganese, while 4140 consists of 0.75-1.00% Manganese and also 0.38-0.43% Carbon.

Characteristics and performance

- 4140 alloy steel has greater hardenability and also strength than 4130.

- 4130 steel is simpler welding than AISI 4140 steel as well as its wear-resistant performance is lower than in 4140.

Usability

4140 is normally more readily offered as well as more affordable in bar and plate types, while 4130 is extra frequently acquired in the tube as well as sheet types.

Machinability

Based upon SAE1212 as 100% machinability, the loved one machinability of AISI 4130 steel is 70%, as well as 4140, is 65%.