Tips for Minimizing Cost of CNC Machining Components

It’s substantial to find a reliable and also cost-efficient CNC machining manufacturer as a long-lasting collaboration companion, which gives quality and also durable services and products for you to expand your business. Thinking about the related aspects, here we’ll review what variables impact CNC machining cost and also how to minimize or lessen the costs of CNC machined parts.

What Aspects Impact CNC Machining Price?

The production time and cost of material will certainly establish the costs of CNC machined parts, prior to you discover a CNC machining company, you can understand the variables affecting the CNC machining cost. In order to supply cost-effective service and high-quality products, our designers will examine and also examine your style after getting the project and then choose the most cost-effective production remedy.

Quantity

The variety of CNC components in one order will influence the overall cost, generally, the bigger the quality, the higher the machining expense, but each added device will certainly be less expensive, which implies that large quantity orders will certainly enhance the overall expense yet minimize the price each. For the same parts, one workpiece needs several procedures and also steps until finished manufacturing, if all the arrangements and also devices just used to run a model example, all of the prices should be assigned to the one component, while if the same procedures and also configurations are made use of to run a huge set of the very same parts, the total price can be allocated over all of the pieces and the price per unit is saved to the maximum extent.

Material

The chosen materials will certainly influence CNC machining expense through 2 means: the expense of raw materials as well as the price of processing. The rate of resources is relying on its very own value and how rare it is, experienced purchase designer will have a basic understanding of typical machining materials, like metals (brass, aluminum, steel, copper, stainless steel), and also plastic (PVC, ABS, PC, Nylon, Delrin), their prices are different as the kinds of materials. The costly materials may have far better performances and also even more durable to make use of. Furthermore, the products that are tough to make will certainly be more pricey in producing cost than various other kinds, the product has poor machinability will likewise enhance the cost. Aluminum, ABS are very easy to reduce, while titanium, as well as stainless steel, are more difficult to process. Designers can select the appropriate materials according to the production applications, demands, and lifespan.

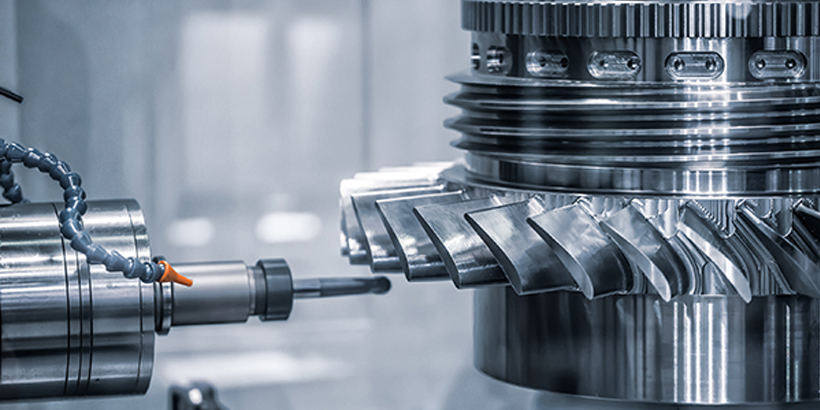

Equipment

CNC manufacturing machines as well as equipment, along with tools or other items also have a terrific effect on the expense of CNC parts. Nowadays, modern devices are not low-cost, specifical tools with several features, like the 5-axis machining centres. The easier machines will certainly set you back less in unit time. The models, dimensions, as well as abilities additionally, add up to the elements that assess the price. The production cost of an ordinary CNC lathe will be lower than the vertical CNC lathe, and also the CNC machining centre will certainly cost even more than a crushing machine.

Geometry and Design

Component geometry will certainly impact the CNC price in many facets. The larger the component, the more products will be required in the manufacturing procedure, which increases the expense. On the other hand, the extra intricate the component is, the machining procedure is harder, and the production cycle will be longer, additionally add the price. The style with features easier to work with will certainly be simpler and save much time, contrarily, if there are some layouts the device is challenging to finish or needs numerous operations to complete, the component will be refined slower and even require to throw out.

Added Process

Some machined components require to be treated with additional treatment, multiple 2nd manufacturing, or surface ending up, every one of these will boost the price, and also if the final product calls for to add some information as well as attributes to the interior/exterior surface, the last item will be absolutely extra costly.

Tolerance and Precision

Limited resistance and high precision always develop higher rates of CNC machining. Normally, the component does not need to set up one-of-a-kind limited resistances unless it’s necessary for detailed scenarios, so developers must submit the drawings based upon the production function. Tight resistances generally are booked for where the component user interfaces with others. Apart from that, tight resistances are especially challenging to accomplish on the inner surface areas of your part, and machining holes or cavities might create burrs, which takes additional time to get rid of. Typical tolerances of DEK products is +/ -0.02 mm or according to consumer needs.

Labour price

Labour price is depending upon great deals of factors, different areas and various industries have various labour expenses, but also for CNC production, Guangdong, China is an excellent place for the manufacturing and also advancement of CNC product or services.

Furthermore, the machinist skill, run regularities, evaluation criteria, tax obligations, environmental, regulations, and also more factors will have an impact on the CNC expense.

How to Minimize CNC Machining Price?

After comprehending the factors impacting the machining expense, the methods to decrease and minimize the price should be based upon these areas.

Design as well as geometry

- Avoid deep cavities.

- Rounded inner corners.

- Make certain the radius of your interior edges goes to at least 1/3 of the deepness of the cavity.

- Decline slim wall (metal components are better with wall thicker than 0.8 millimetres, plastics can pick 1.5 millimetres).

- Limitation of the thread length (set a maximum length of 3 times the hole size).

- Avoid small functions with high width-to-height element proportion.

- Optimize tapped holes.

Tolerance

- Decrease the use of tight tolerance.

- Use standard tolerance of ± 0.125 millimetres or much better.

- Remove all unneeded decimal points from your design.

Tool

- Leverage standard drill sizes.

Extra treatment

- Stay clear of surface treatment.

- Choose the as-machined finish.

Others

- Select bigger amounts orders.

- Select a more economical location.

- Factory with skilful machinist ability is better.