Guide to Face Milling

Face milling is a reliable process to achieve the outstanding surface finishing on the CNC milling components, what’s the scientific research of it? Discover what is face milling and the style of face mill, perhaps you can find some helpful ideas for improving your face milling procedures. As the different demands, contrasting two types of the milling procedure, we likewise lay out the distinction between face milling as well as peripheral milling.

What is Face Milling?

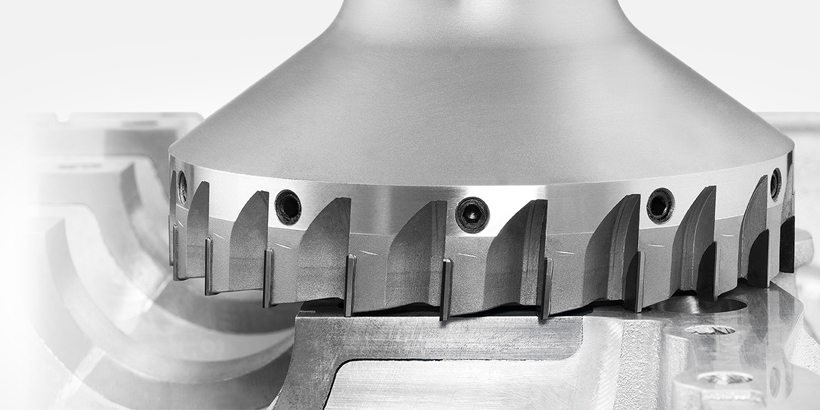

Facing with milling is a milling procedure in which the revolving axis of the cutting device is perpendicular to the surface is being machined, made use of to create level surfaces. Which is the very best face milling device? The face mill is the cutter made for encountering, covering mills and also fly cutters are most often made use of for face milling, while end mills can likewise aid you to obtain the various surface. The face milling procedures consisting of basic face milling, high face milling, durable face milling and also do with wiper inserts.

Exactly how Does the Face Mill Work?

Face mills are typically obtained grating a face externally of a plate or bar. The cutting of face milling is primarily with completion of the cutter rather than their sides. Multiple teeth on the cutter can distribute the chip load and also the teeth on the periphery of the cutter can finish almost all of the cutting effectively, when the cutter is correctly ground, the face teeth really remove a percentage of stock which is left as a result of the springing of the work surface or cutter, then achieving a smoother surface finish.

Distinction Between Face Milling as well as Peripheral Milling

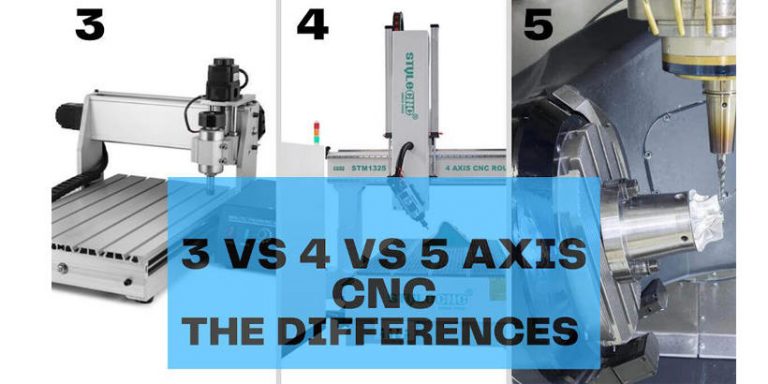

- The cutting tool of face milling is put vertical to the milling component, while the cutter of outer milling is placed alongside the component.

- In face milling, the idea of cutter presses against the workpiece, while in peripheral milling, the sides of the cutter grinding away on top of the work surface.

- In face milling, the cutting is finished by the level face of the milling cutter of which axis is vertical to the surface of the item, as well as in outer milling, the cutting is accomplished by the peripheral teeth of the cutter.

- For peripheral milling, the teeth are just situated on the perimeter of the cutter, while for face milling, the cutter teeth are on both the periphery as well as the face.

- In face milling, most of the cutting is done by the peripheral teeth and teeth on the face of the cutter can give ending up operation, as well as peripheral milling can be made use of for machining flat and made surface relying on the axial contour of the cutter.

- Face milling can be done on both horizontal and also upright spindle devices, while peripheral milling normally carried out on horizontal spindle makers.

- Peripheral milling is extra reliable at getting rid of large amounts of materials while face milling provides a far better surface area finish. And also face milling is a favoured selection when needing to get rid of a very little quantity of materials.

Tips for Face Milling Operation

Right here are some tips as well as tips that include material choice and operation information for far better results of face milling machining.

- Fly cutter is a lot more ideal for refining softer materials like aluminium

- Shell mill is advised for cutting steel

- The position of the cutter ought to be off-centre from your work surface when face milling

- Prevent exiting as well as getting in of the workpiece frequently

- Maintain your tool paths on your face milling part as much as possible.

- Stay clear of face milling over holes or slots

- The workpiece must be fed versus the milling cutter to ensure that the pressure of the cut is downward, thus holding the piece against the table.

- When setting the deepness of the cut, the component should be raised to touch the revolving cutter.