Guide to CNC Acrylic

Acrylic is just one of the most pre-owned clear plastic in CNC systems. This material uses considerable benefits over various other products like polycarbonate and also glass.

CNC acrylic machining is among the most noticeable processes for acrylic production. Many sectors make use of acrylic components. As a result, it ends up being essential to look into its manufacturing processes.

This article supplies you with a complete overview of CNC acrylic. You will certainly also discover the very best tips for machining acrylic. Before-after that, allow’s understand what Acrylic is as well as what makes it essential.

What is Acrylic?

Acrylic is a rigid and also clear polycarbonate material. It is likewise referred to as Polymethyl methacrylate (PMMA). Several markets utilize acrylic as a replacement for glass because it is unbreakable. It is colourless as well as a clear polymer that can come in different kinds. For instance, it comes as tiny granules, pellets, or sheets.

Machinist then utilizes various polycarbonate processes for acrylic CNC cutting. Such processes include compression molding, shot, and also extrusion molding.

Some producers make use of cell casting for their acrylic CNC layout. Acrylic has an extremely high molecular mass, making it a hard material. It is additionally 100% recyclable.

Appropriate Processes for PMMA

Polymer appropriates for handling by a variety of machining approaches. These consist of injection molding, plastic extrusion, casting, as well as several others. Depending upon the recommended thing style, acrylic manufacture may involve some or all of the following processes.

CNC Machining

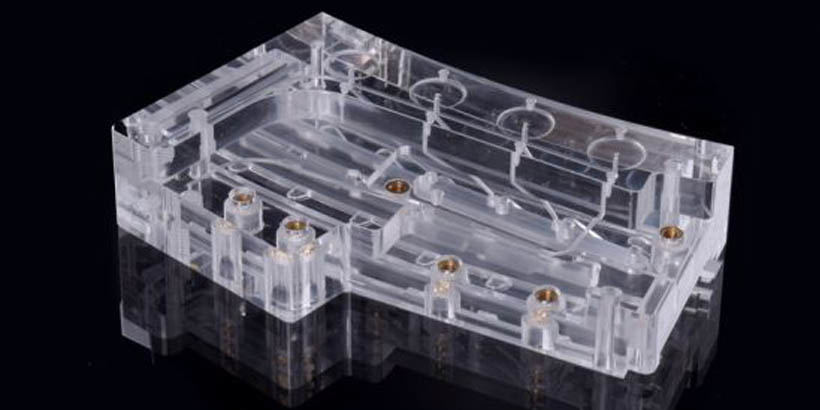

PMMA has actually numerous boosted buildings that makes it appropriate for a wide variety of applications. All of these applications need the highest level of precision and surface area finish. CNC acrylic machining is the process of making acrylic materials.

Being a rigid as well as strong product, CNC machining is always the ideal remedy for acrylics. That is, you get the result that associates with the input criteria you feed right into the acrylic CNC machine.

Compounding (Blending)

While the welding functions to bond two acrylic pieces into one, worsening blends the melted pieces prior to molding happens. The purpose of intensifying is to develop a product with functions of various polymers. This will certainly make certain that the product meets the preferred top quality. In most cases, products resulting from this process are commonly more resilient than raw materials.

Since PMMA is transparent as well as fairly tough, it can also be employed as a 3D printing product. In this instance, it’ll need a slightly greater temperature.

Injection Molding

Equally, as with other plastics, it is feasible to develop acrylic into detailed forms. This is done by warming the acrylic. You can place the heated acrylic into a mold and mildew where it will certainly harden and cool.

The molding treatment can be injection molding or rotational molding. Shot molding is specifically preferred for producing crockery. On the other hand, rotational molding assists to create hollow plastic parts.

Acrylic Extrusion

This process assists acrylic fabricators to enhance the processing of their materials. It usually precedes the bonding or lamination stages.

Several producers use this procedure for piping, tubing, and sheeting elements. There are 2 forms of acrylic extrusion in operation. They are profile extrusion and also sheet extrusion. Both processes have a performance history of offering the wanted results.

Acrylic Welding

This is a binding operation that uses heat to sign up with 2 or more acrylic assemble. In this situation, there won’t be a need for using adhesives, particularly when they are not feasible options.

The acrylic welding procedure may include getting in touch with welding, high-frequency vibration, spinning, or warm gas discharges.

Features of Acrylic

CNC acrylic exhibits qualities that make it work like glass. These qualities include translucence, clarity, transparency, as well as brilliance. It is just one of the most robust materials used in production. It also has minimal threats of damages. Allow’s to look at the different features of acrylic thoroughly.

- Surface Firmness. Acrylic is a lightweight, hard, and also long-lasting polycarbonate. Its density varies from 1.17 g/cm3 to 1.20 g/cm3. When you compare it to various other transparent polymers, it has excellent scratch resistance. In addition, acrylic has superb dimensional security. This gives it low water or wetness absorbing capacity.

- Chemical Resistance. Liquid solutions of most laboratory chemicals do not influence acrylics. You can use cleansers, antacid, detergents, thin down inorganic acids, as well as others on acrylic. You will not need to fear harming the material.

- UV Stability. Acrylic is highly immune to UV light. The majority of CNC acrylic styles make sure UV stability. Thus, they are resistant to prolonged sunlight exposure. This property likewise makes acrylic an excellent option for outdoor applications, particularly for more outdoor exposure.

- Transmittance. Acrylic polymer comes with a refractive index of 1.49. It ends up being simple to have personalized acrylic plastic without losing optical clearness. Its environmental stability makes it useful for many outdoor applications.

Applications of CNC Acrylic Components

Polymer (PMMA) came to be prominent throughout the second world war. At the time, it was made use of to make gun turrets, canopies, windscreens, and so forth. A number of other industrial applications started ahead up.

They consist of roof covering, auto headlamps, and also a lot more. Today, several industries utilize a variety of acrylic qualities. These markets consist of:

Medical as well as Health care

Acrylics are pure and also easy-to-clean products. They are valuable in making incubators, cupboards, as well as devices in medical.

Automotive Industry

Acrylic sheets are utilized to make car home windows, panels, bike windscreens, fenders, etc. The colored sheets are ideal options for various automobile components.

These include indoor light covers, indication light covers, and others. Its exceptional formability and surface firmness make it a wonderful selection for carmakers.

Architecture and Construction Industry

A lot of construction functions make use of acrylic components. This is, partly, a result of its impressive UV and also impact resistance.

It is a wonderful product for windows and door accounts, panels, covers, appearance styles, and also a lot more.

Some of the most common items you can make from acrylic sheets include:

- Glove boxes.

- Illumination fixture lenses.

- Display and signs.

- Radiation shields.

- Aircraft glazing.

- Desiccators and also dry boxes.

- Retail fixtures.

- Windows and glass alternatives.

- Sinks, baths, batons, and knobs.

- Automotive components consisting of fascia panels, steering wheel, and badges.

Lighting and Electronics

Acrylics make the best use of the light-emitting potential of LED lights. Its optical residential properties and openness make it excellent for light building and construction. It has a high light transmission home. Polymers are optically clear as well as scratch-resistant. Thus, their considerable usage in a variety of electronic tools.

Pros of Using Acrylic for Your Parts

Polymer is a preferred material, many thanks to its superior characteristics. These properties tell us that machining acrylic components are sturdy, clear, as well as immune.

- Exceptional weathering as well as resistance to UV radiation.

- Good rigidity.

- Dimensionally stable.

- Good abrasion resistance – you can quickly polish out surface scratches.

- Transparent.

- High gloss and also firmness after modification.

Tips to Obtain the Best Arise From Machining CNC Acrylic

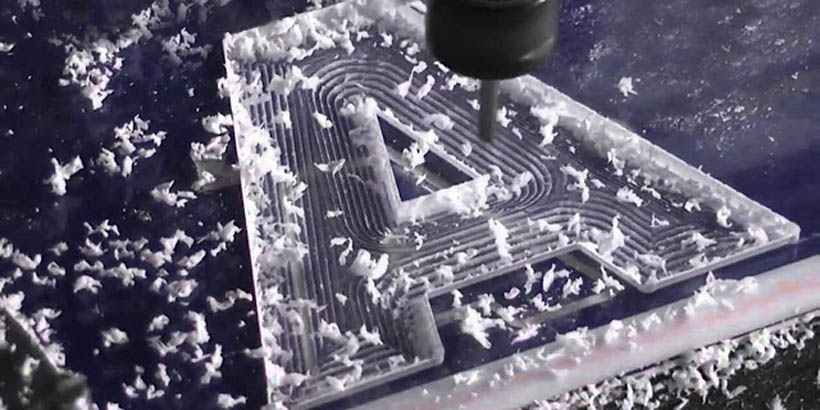

Making use of acrylic on your CNC system is among the best decisions you can make for your part. You can accomplish a variety of collaboration with CNC acrylic. There are some suggestions you ought to understand to make certain successful manufacture.

Complying with ideas will certainly help you obtain a smooth surface from your acrylic CNC cutting.

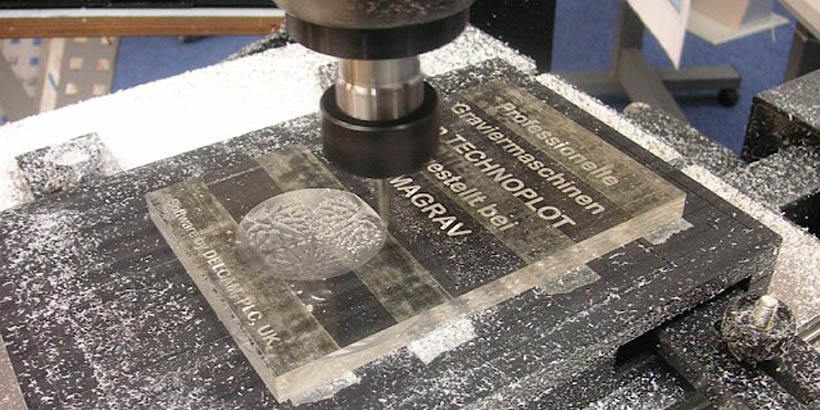

Make Use Of the Correct Bit

Making use of wood a little bit for cutting acrylic on CNC is never the very best concept. Always utilize a little bit made especially for acrylic cutting.

Use the Correct Revolution Per Minute (RPM)

The RPM you utilize has to associate with the feed price. The sort of acrylic you make use of will certainly establish your settings. A faster RPM will certainly require you to increase your feed price. Hence, you can stop the melting of your material.

Cut Directions is Important

Traditional or clockwise instructions has a record of generating the very best results. This is commonly best in regard to the direction of the rotating cutter.

Set the Pass Depth at the Correct Inch

The most effective pass deepness for most products will be half the size of the bit. Some products need a pass deepness of 0.0625″ for the best outcomes.

Set the Right Feed Rate

Ensure that you utilize the right feed rate for your procedure. This will make certain that you get excellent clean cuts. You will not likewise have to melt your plastic as you’re cutting it.

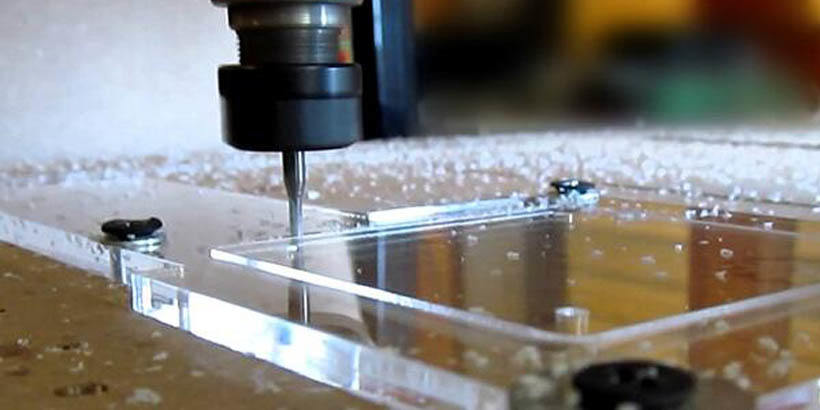

Secure Your Material

Machining acrylic is a fragile procedure that needs cautious procedures. It is extremely vital to protect your acrylic effectively to your device. Refraining from doing this might result in excess vibration that might destroy the top quality of the item.

Don’t Neglect the Ramp Feature

When working with CNC acrylic, it is advised to utilize a ramp. The ramp helps the little bit enter your material at the needed angle. It will not just dive right down. Using a smooth ramp between 1 to 3 inches will offer the wanted results.

Final thought

Acrylic is one of the best materials you can collaborate with on CNC systems. There’s a lot you can do with this material. This post has actually led you to the various benefits and also applications of CNC acrylic. You also currently have the very best standards for machining acrylic. It’s time to get your customized acrylic plastic.

DEK is your go-to business for CNC machining needs. We are constantly ready to achieve the best outcomes within a reasonable preparation. With the help of our educated and skilled designers, we carry out a reliable CNC milling acrylic procedure. We make high-quality services our top priority at DEK.