Guide to Find a Good CNC Machining Supplier in China

A reliable CNC provider machining can aid you to save price as well as broaden the business scope. China is a vast country with great deals of benefits, how to find a provider in China? Below are some ideas for choosing the best CNC component manufacturer.

Evaluate the CNC machining market

You require to recognize who is the leader of the CNC machining services market, what is the development trend of the market presently, as well as what is placing of the significant suppliers, so regarding having a general understanding of potential selections. You can establish a preliminary provider data source based upon these analyses.

This step will certainly take a lot of energy and time as a result of the opaque details in the industry, so it’s really beneficial to pick a B2B platform with a great online reputation, like alibaba.com and also made-in-china. com, they have integrated a lot of premium vendors with their item and also firm details, search for the CNC component supplier according to the business kind, processing, material or other features, you can significantly conserve the moment.

Select qualified machining suppliers on the basis of certain problem

Identify the essential areas or factors that you require to concentrate on as well as validate, evaluate the information, as well as remove the suppliers that are undoubtedly not ideal for further participation, then you can obtain a list of certified CNC machining providers. Right here are some factors you need to consider:

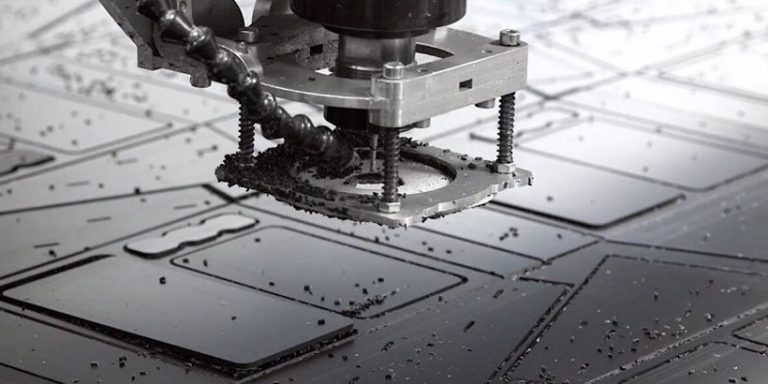

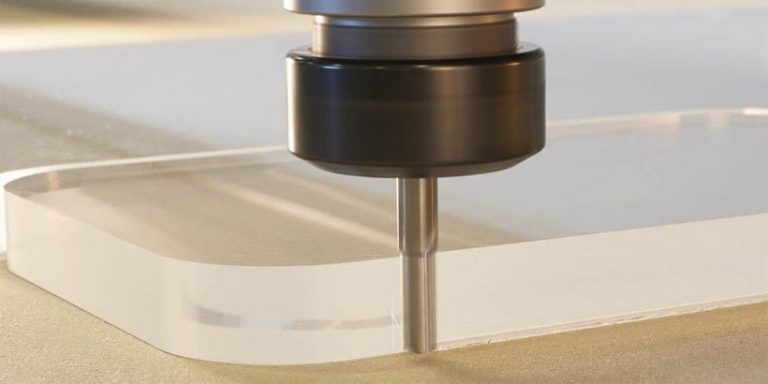

Quality and process control

The quality control of CNC machined parts is a crucial issue you require to consider. To guarantee your supplier has robust testing and also verification protocol, check out the total proof and traceable bar codes or identification numbers, to prevent unqualified or phoney materials. In terms of product quality, know if the company has passed relevant qualification or satisfies certain policies. You can request the screening and also high-quality reports before delivery.

The procedure control and also management is likewise crucial, the item quality, as well as effectiveness, do not only depend on the devices as well as makers the supplier makes use of, likewise via control and also management via the whole process, entailing the techniques, programs and also more. DEK is an ISO9001:2015 certificated supplier with strict quality and process control to make certain each action finished as consumer needs.

Experience

Typically, knowing the time that the supplier has actually been operating is likewise valuable details in the CNC manufacturing industry, one of the most specialist and qualified CNC component producer and also CNC services provider will be the one that has actually stayed in business for years, just good reputation and also the high quality can sustain the long-term advancement of a business. Experienced suppliers have built up huge expertise in the location as well as skilled to handle the troubles. DEK is a 19-year CNC machining firm with high productivity and also solid capability.

Minimum Order Quantities (MOQ)

Most China distributors have a MOQ, the volumes can stand for a considerable first investment. If you are creating a model, the supplier with lower MOQ is likewise far better to work with.

Delivery Time

Whether products are supplied promptly are relying on lots of elements, such as amount, size and also the intricacy of the part, raw material, etc., the shipment time for sample and mass production is likewise various, furthermore, the remaining batches after the very first production should be more effective, you should interact the commitment regarding the shipment time plainly with the vendor beforehand.

Client Service

If you have no experience purchasing separately from China provider, customer service is a vital component. Consumer solution entails pre-sales, sales and after-sales solution.

Field visit to machining suppliers

When essential, translators, top quality divisions and product engineers can be invited to take part in the audit group. They will not only bring specialist understanding as well as experience, however likewise contribute to interaction and coordination within the company. In the field investigation, you can observe the scale of suppliers, production capacity as well as various other aspects, in addition to the procedure monitoring system, which is helpful to master even more actual information.