Guide to Hardness in Mechanical Engineering

Hardness is a property of the material to figure out whether it can work in a detailed application, as well as there are several sorts of hardness tests to determine the ability. In this short article, we’ll get right into the hardness in mechanical engineering, introduce different types of product hardness and also common solidity ranges.

What is Hardness in Mechanical Engineering?

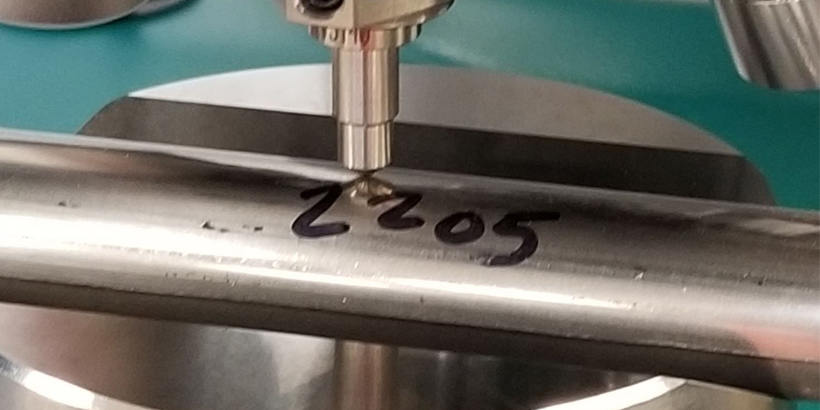

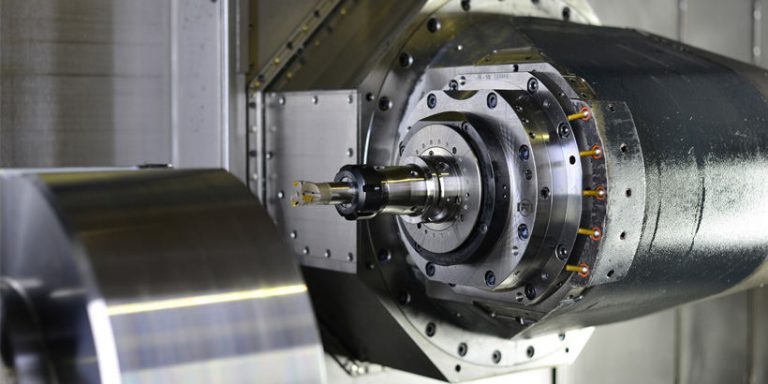

Hardness refers to the capacity of a material to resist local plastic deformation triggered by mechanical imprint or wear. Plastic contortion likewise called long-term contortion indicates that the product will certainly not return to its original form. hardness depends on ductility, elastic rigidity, plasticity, strain, toughness, sturdiness, viscoelasticity, and thickness. The local resistance of solid to the invasion of outside things is an index to contrast the hardness and soft qualities of different products. Various products generally have various solidity, usual tough products are porcelains, ruby as well as tough steel such as titanium, while wood and common plastics are softer. Cemented carbide, which is a typically used material of CNC milling cutters, is a hard material.

Kinds Of Material Hardness

Hardness can be analyzed by a variety of methods, there are mainly three types of hardness dimensions: scratch hardness, indentation hardness, and rebound hardness.

- Scratch Hardness: measures the resistance of an example to irreversible plastic deformation due to rubbing from sharp things. Materials that are much less influenced by damage will certainly have higher scrape hardness. The most common scrape hardness examination is the Mohs range for mineralogy.

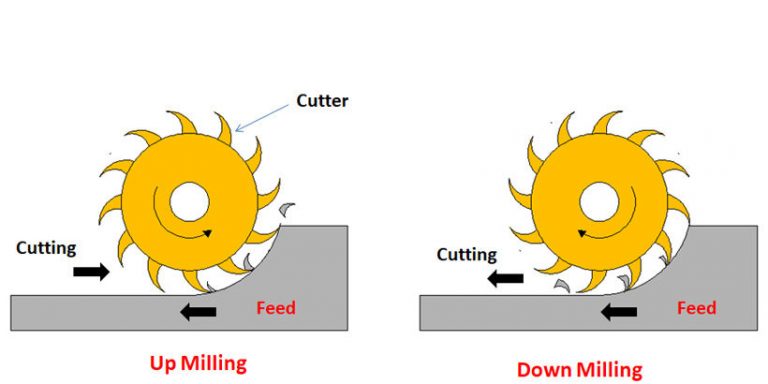

- Indentation Hardness: measures the capacity to endure surface area impression and the capability of the measured sample to resist contortion under the constant load of a sharp item. The higher the indentation solidity, the greater capability to not have any kind of resulting contortion from applied compression. Indentation hardness mostly used in the design and also metallurgical fields. The traditional imprint solidity test method is making use of tough indenters of specified sizes as well as geometries to push right into the material under a specific force, as well as record the contortion parameters like imprint depth. Common impression hardness ranges are Brinell, Rockwell as well as Vickers.

- Rebound Hardness: also known as dynamic solidity, measures the “bounce” elevation of the ruby hammer when it drops from a dealt with elevation to the product. A product with greater rebound solidity will bring about a higher bounce when the hammer is dropped. This hardness is connected to the flexibility of the material under examination. The determining tool of rebound solidity is called a sclerometer.

Types of Hardness Scales

Different hardness ranges include Rockwell C & B (steels), Brinell (ball indenter, metals), Vickers (diamond-shaped indenter), Knoop (diamond-shaped micro-indenter), Meyer (hardly ever used), Coast A & D (rubber & softer plastics), and Mohs (minerals). The unit Pascal is also used for hardness. The various kinds of solidity have various determining scales.

Common hardness units

- Brinell hardness (HB): procedures the impression hardness of products via the range of infiltration of an indenter, packed on a material test-piece. BHN stands for Brinell hardness Number, which coincides definition of HB. The Brinell hardness examination is frequently used to establish the solidity of materials like alloys and also metals.

- Knoop hardness (HK): determined by gauging the imprint generated by a ruby pointer that is pressed onto the surface area of the example. It is utilized especially for very slim sheets or breakable products, where only a little indentation might be created screening objectives.

- Rockwell hardness (HRB, HRC, and so on): based upon the indentation hardness, measures the depth of infiltration of an indenter under a large load (significant lots) compared to the penetration made by a preload (minor load). Due to the various indenters or tons, there are numerous alternative ranges, such as HRA, HRB, HRC, HRD, and so on, the most frequently utilized are HRB and also HRC ranges. They both express hardness as an arbitrary dimensionless number, HRB is usually utilized for aluminum, brass, and soft steels, and also HRC is used for harder steels.

- Shore A & D: Coast hardness is a step of the resistance of a material to the infiltration of a needle under a defined springtime pressure. The letter A is made use of for versatile types and also the letter D for rigid kinds. Shore A hardness scale gauges the hardness of flexible mold rubbers that range in solidity from flexible as well as very soft, to the tool and somewhat adaptable, to hard with nearly no versatility. Shore D solidity is specified for tougher elastomer measurements making use of a needle that finishes with a 30 ° point angle and also is not blunted.

- Vickers hardness (HV): compute the hardness by optically determining the angled lengths of the impression left by the indenter, after that transforms the measurements to HV using a table or formula. The Vickers test is much easier to utilize than other solidity examinations and also can be utilized for all steels, among the best scales among solidity tests. The system of Vickers hardness is known as Vickers Pyramid Number (HV) or Ruby Pyramid Hardness (DPH).

- Mohs: one of the most essential tests for recognizing mineral specimens, gauges a mineral’s resistance to scratching.