Guide to Laser Cutting

Laser cutting is a process that uses a laser to reduce products and jobs by directing the result of a high power laser most generally via optics. Laser cutting is generally used for commercial producing applications. Nonetheless, it is getting down to being used by small companies, institutions and also enthusiasts. The [laser optics] as well as CNC (computer system numerical control) are units accustomed to guide the textile or the beam of light generated.

A commercial optical maser for reducing materials requires a movement system to adhere to a CNC or G-code of the pattern to be cut into the material. The centred beam of light is directed at the fabric, that then either thaws, burns, evaporates away, or is blown away by a jet of gas, making an edge with a premium surface end. Industrial optical maser cutters are for cutting flat sheet product and structural and also piping materials.

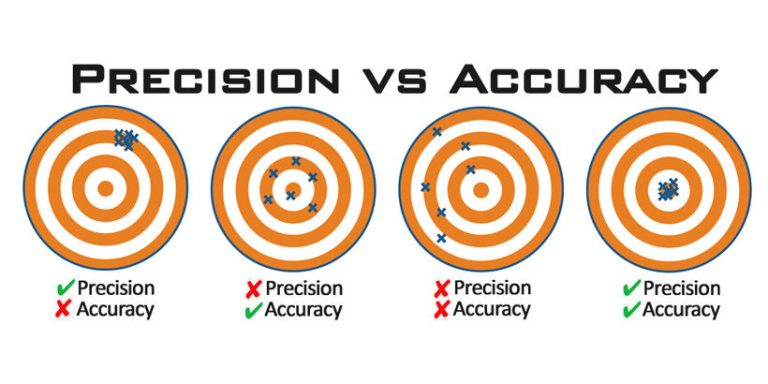

How correct is laser cutting?

Cut breadth is commonly really little with optical maser cutting, however, zero.001 inch, as well as dimensional accuracy, are very precise, relating to ± absolutely no.0005 inch. This accuracy is incredibly useful for producing the jagged teeth used in some cutting devices.

What are the cons of laser cutting?

Laser cutting has the cons of high price and also terrific energy intake. Laser cutting of plastic parts are often pricey as a result of once revealed to warm, plastic releases gas.

What are the means of laser cutting?

Means of laser cutting include melt blow as well as burn, blow as well as melt, evaporation, scribing, thermal stress and anxiety splitting, cool cutting and burning stabilized laser cutting based upon various materials.

About DEK

DEK, found in 2002, was a machining factory at the beginning. For decades, through continuous investment in equipment, and continuous investment in other companies, now DEK is a China leading full services company of CNC machining, precision machining, 3D printing, plastic injection moulding, which helps customers achieve their products from design to mass production.

If you need a prototype, medical equipment parts, precision aluminium parts, or any other plastic and metal parts, there is no better supplier than DEK. We have a variety of processing equipment and sophisticated testing equipment, enough to deal with any complex or tight tolerance products.