Precision VS Accuracy, What is the difference?

To evaluate the measurement causes CNC precision, machining as well as accuracy are 2 commonly made use of concepts. This short article, allow’s to learn more about precision and accuracy meaning, what is the difference between accuracy and also precision, along with the partnership between precision, accuracy as well as tolerance for machined parts.

What are Precision and Accuracy?

Precision refers to the closeness of the measurements to each other, which means that if the gauged worths are all close to each other, then they are exact. The CNC machining precision shares the reproducibility of the measured size, length, and also various other values of the machined component and reflect the influence of accidental mistake. Precision machining normally refers to a machining procedure holding close tolerance or getting rid of material as well as create machined components with resistances in a tiny range.

Accuracy is specified as the distance of the measurements to a particular value or real outcome. If the measurements are all near to real worth, so they are accurate. It can reflect the influence of system error. If the system error is little, the accuracy is high. An effectively made work surface should have both high accuracy and also precision.

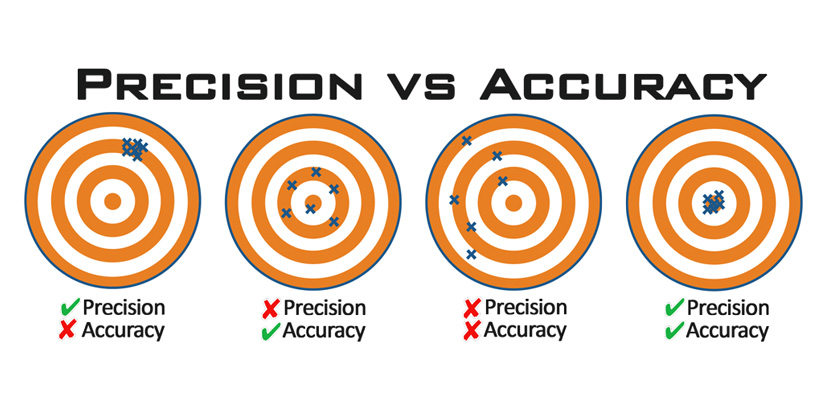

The Difference Between Precision as well as Accuracy

Accuracy and precision are both reflect how close a measurement is to an actual worth, yet various considerations need to take when examining them due to precision and also accuracy distinction.

- Meaning

Accuracy refers to the level to which the ordinary value of multiple measurements under certain experimental conditions follows real worth. While precision describes the consistency (consistency) between all measured worths after repeated dimensions under the exact same conditions. - Mistake

Accuracy reflects system error, while precision reflects arbitrary mistake. - Measurement times

Accuracy can be observed by one dimension while many measurements are needed to evaluate precision.

What’s the Connection In Between Accuracy, Precision and Tolerance?

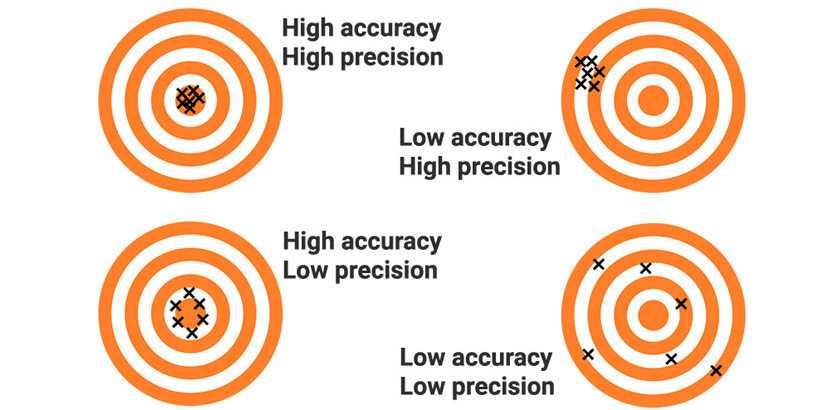

What we should note is that high precision not indicates high accuracy, as well as also if the measurement is accurate, not offers it’s specific. Accuracy is the primary factor you need to consider when selecting a CNC machining manufacturer, it is related to the item high quality. There are 4 situations of your CNC machined parts:

- High accuracy, high precision.

- High accuracy, low precision.

- Low accuracy, high precision.

- Low accuracy, low precision.

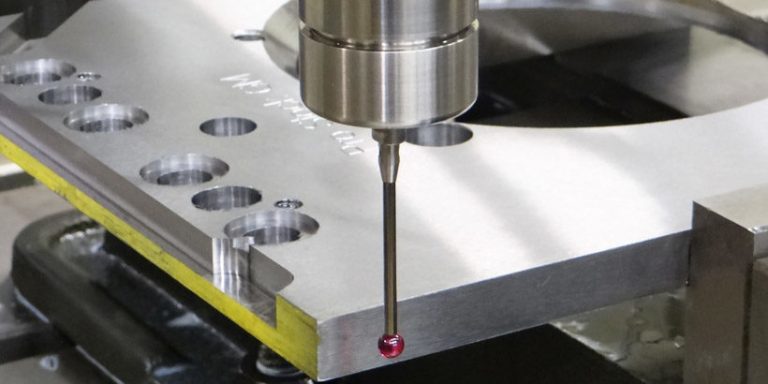

On top of that, the precision is gauged by specifying tolerance. The tolerance specifies the variance far from a well-known worth, expressed as a “+/-” number, such as +/ -0.005. Sensible tolerances are allowed for CNC machine tools for natural activity.