Guide to Machining PVC

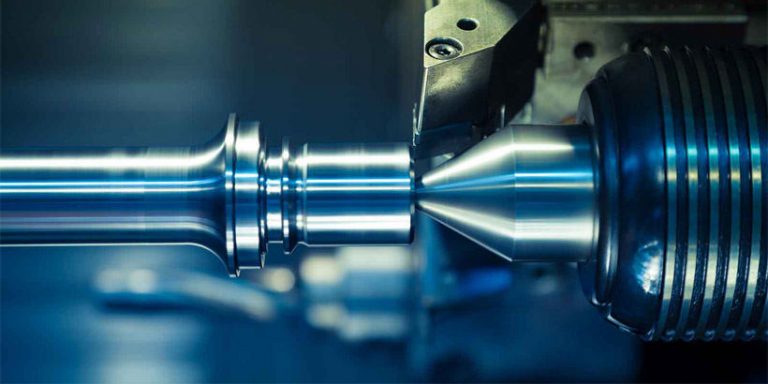

The unique Polyvinyl chloride properties make PVC a popular plastic material in CNC machining and also manufacturing for various applications and also demands. Various other than the plastic machining tips, DEK also provides a choice of affordable PVC machining solutions as well as custom PVC machined components to specific requirements.

What is PVC (Polyvinyl Chloride)?

Polyvinyl Chloride (PVC or Vinyl), is a synthetic plastic polymer that has the third-largest manufacturers in the world, is available in 2 standard kinds: rigid as well as inflexible. Pure polyvinyl chloride is a white, fragile solid. PVC is a material that’s chemically nonreactive, which permits it to be made into a wide variety of products.

Pros of PVC

The mix of PVC properties, as well as features, makes it provide benefits that are tough to match for many uses, specifically the rust immune applications.

- Tasteless, odourless and nontoxic

- High corrosion resistance

- High chemical resistance

- Low moisture absorption

- Excellent electrical and insulating properties

- Good dimensional strength and high impact strength

- Highly machinable, can be machined to close tolerances and finishes

- Fire resistance and chemical bondability

- Durable and light, low-cost

What is PVC Made use of for?

Rigid PVC appropriates for applications like pipeline building, doors, windows, accounts, containers, non-food packaging, charge card, thick sheet in corrosion immune applications like tanks, air ducts, fume hoods, and pipeline, etc. While adaptable PVC is extra ideal for electrical cable television insulation, floor covering, plumbing, signs, options to rubber, etc.

With CNC machining services, PVC can be made into rings, bushings, put on parts, rollers, digital parts, semiconductor parts, pads, spacers, insulators, pipeline and also shutoff components, fittings, coupling, and also personalized developed PVC produced components.

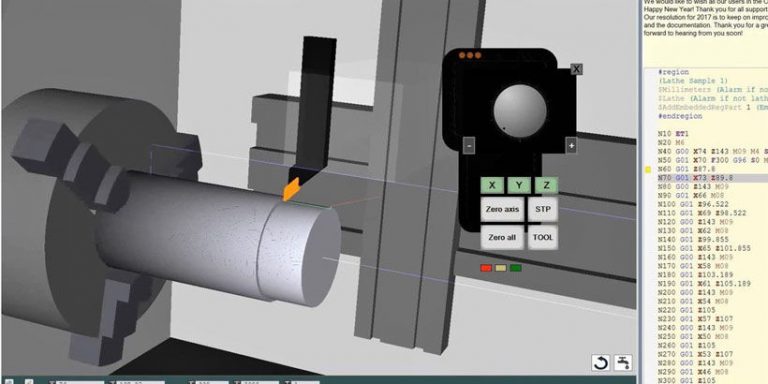

PVC CNC Machining Tips

For enhancing the high quality of PVC machined components manufacture, there are many vital elements to account for.

- Select the right cutting tool: plastic is fairly unstable in machining, only appropriate devices can guarantee safety and security as well as dependability throughout the production process.

- Handling conditions: please note that its greatest operating temperature is from 100+ F to 200+ F.

- Arrangement factors to consider: consisting of PVC machining rates, rubbing, attack angle, stress as well as tooth-counts. For machining PVC, it’s far better to collaborate with lower speed and also as little force as possible.

- Clear the chips away from the part instantaneously, make use of the coolant properly.

- CNC milling: utilize either high positive or high shear geometry cutter in face milling

- CNC drilling: utilize slow-moving to medium speed and also just mild descending pressure. When drilling 1/4-inch or bigger openings, pick spade little bits or little bits especially for drilling plastics.

PVC CNC Machining Service

DEK has gathered decades of experience in OEM CNC lathing, and also is capable to produce quality PVC parts as well as personalized plastic fabrication solutions that meet customers’ demands and expectations, positive prices and on-time shipment will be ensured.

- CNC design and also engineering: custom-made parts and also tooling.

- Accuracy CNC machining service: milling, turning, drilling, grinding, milling and turning, along with surface completing.

- Facility framework and also limited resistance.

- Small, tool to large manufacturing or prototyping.

- Product option and style recommendations.

- Quality assurance, as well as testing of finished PVC, machined parts prior to distribution.