Overview to The Main Steels Utilized In CNC Machining

There are great deals of materials used for CNC machining, which material is best as well as exactly how to choose the most ideal for your CNC project? In this post, we reveal some main sorts of steels made use of in CNC & finest CNC materials.

Tool Steel For CNC Machining

Tool steel is primarily made use of for manufacturing cutting tools, determining devices, mold and also various other tools, so the product is required to have high firmness and also wear resistance, certain durability, small warmth treatment contortion, great dimensional stability as well as various other residential properties, so the steel not just consists of high carbon web content, yet likewise consists of more alloy elements. Grade, composition, warm therapy, properties and application of common tool steels.

Alloy Steel For CNC Machining

Compared with carbon steel, the hardenability of alloy architectural steel is much better. When the performance requirements of components are repaired, alloy steel can be made use of to make large-size parts. When the hardenability deepness of parts is repaired, alloy steel can be used to satiate with a slower cooling rate, so as to get the called for mechanical homes, resulting in adverse results on the recurring tension as well as the mechanical properties The threat of splitting and also deformation is minimized.

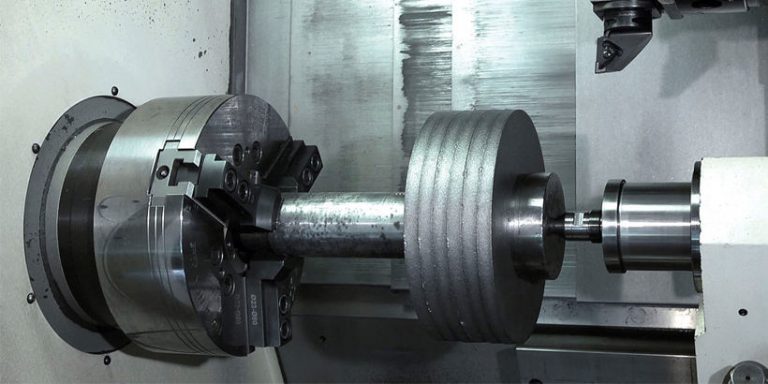

Structural Steel For CNC Machining

Structural steel is the most commonly used material for CNC machining. It is mainly used to produce various fundamental parts of accurate machinery and instruments, such as shafts, ports, equipment as well as springs. It has high requirements for the stamina, plasticity, hardness as well as influence sturdiness of steel. The mechanical buildings of steel mainly rely on the make-up and also warm therapy of steel. Structural steels include carburized copper, Quenched and tempered copper, spring copper and ball bearing steel.

Carburized steel has reduced carbon content as well as good sturdiness, so it appropriates for mushroom parts that bear a particular impact. After carburizing, relieving and low-temperature tempering, the surface has high wear resistance, while the core has high influence toughness. The carbon content of relieved as well as tempered steel is medium, and also after solidifying and satiating (high-temperature tempering after relieving and toughening up), it has excellent comprehensive mechanical buildings, After surface area quenching treatment. Spring steel with high carbon material has high flexible restriction, yield limit and yield strength ratio (Q/ V) after quenching as well as tool temperature tempering. In order to enhance the exhaustion efficiency of springtime, shot peening is widely made use of. Quality, composition, heat treatment, properties and also application of common carburized steel, quenched and tempered steel and also spring steel.

Sleeve bearing steel is a sort of unique structural steel, which is primarily used to make moving sleeve bearing hydraulic body (ball, column, needle), inner and outer rings, etc. Due to the fact that the bearing steel has high carbon, it has high hardness and also uses resistance; The bearing steel is generally heated by an electric furnace and also vacuum degassing, so the content of S and also P is reduced, which is more conducive to enhancing the call fatigue stamina of the steel. For that reason, it is additionally utilized to make accurate measuring devices, accuracy screw, cold stamping die as well as other wear-resistant components. Grade, composition, warm treatment, buildings and also application of typical bearing steels.

Stainless Steel For CNC Machining

Stainless steel has high corrosion resistance in the environment and general media and also is extensively used in oil, chemical market, atomic energy, aerospace as well as some advanced science as well as modern technology. It is mainly utilized for making numerous containers, shutoffs, pipes as well as pumps, medical surgical instruments, antirust cutting tools and measuring devices.

The most essential requirement for stainless steel is deterioration resistance. The stainless steel for tools also requires high hardness and also use resistance. Stainless steel is a kind of high alloy steel that generally consists of steel and irons.

Stainless steel can be split right into martensitic stainless steel as well as austenitic stainless steel according to the stabilized structure. The warmth therapy of martensitic stainless steel is similar to that of architectural steel. After quenching, it can be solidified at different temperature levels to fulfil the demands of various components. The deterioration resistance, plasticity and also durability of austenitic stainless steel are much better than those of martensitic stainless steel, but the stamina, as well as solidity, are reduced. The grade, composition, heat therapy, buildings and also application of generally utilized stainless-steel.