Guide to Stainless Steel for Machining

In the construction sector, stainless steel plays a considerable role, the products made from stainless steel are extensively utilized in different applications, the use of CNC machining service gets over some troubles in the manufacturing as well as raises performance. Right here we are presenting the stainless-steel properties, machining process and also suggestions, surface area coatings, as well as extra.

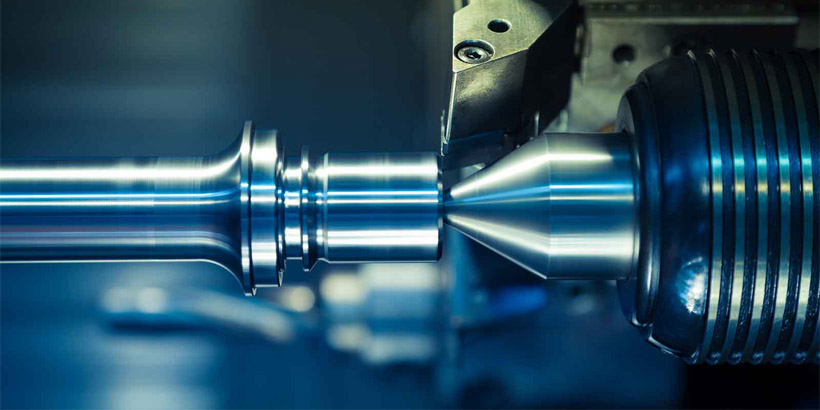

CNC Machining Services for Stainless Steel

Stainless steel machining or manufacturing is the procedure of cutting, folding, bending, welding and various other mechanical handlings to get the needed stainless steel products. In the process of stainless steel machining, a lot of machines, tools, and tools are working. The difference between stainless steel CNC machining and also typical machining is that the former one is through controlling the procedure of the device by digital modern technology to finish the specific motion and also generate the designed products.

Stainless-steel Properties

Stainless steel is a steel alloy, consists of a minimum of 10.5% chromium, less than 1.2% carbon and also various other alloying elements. The attributes of stainless steel make it a perfect product for CNC machining. One of the most remarkable features of stainless steel is its rust resistance, which enhances the rising of chromium web content. The mechanical properties of stainless steel can be better boosted by including other aspects, such as nickel, molybdenum, titanium, niobium, manganese, etc. Stainless steel additionally has more advantages:

- Resistance to discolouration reduced maintenance, and also familiar lustre

- High toughness, tensile strength, ductility

- Temperature level resistance, wear resistance

- Can be conveniently welded, machined as well as polished

Types of Stainless-steel

Below are some typical stainless-steel collection and also kinds. Stainless steel can likewise be categorized into austenitic, ferritic, martensitic, rainfall hardening, as well as duplex based upon the metallurgical framework, or different collection as below.

- 100 series: 102

- 200 series: 201, 202

- 300 series: 301, 302, 303, 304, 304L, 304LN, 305, 308, 309, 310, 316/316L, 316Ti, 321

- 400 collection: 403, 405, 408, 409, 410, 410S, 410HT, 416, 416HT, 420, 422, 430, 439, 440, 446

- 500 series

- 600 collection: 601, 610, 614, 630 (17-4 PH), 650, 660

- 900 series: 904

- Duplex: Duplex 2205, Duplex 2304, Duplex 2507, LDX2101

Stainless-steel Surface Therapy Approaches

Surface finishing service is commonly applied to improve the corrosion resistance and change the look of stainless-steel parts, however a rough surface area finish can decrease the deterioration resistance, do not exaggerate the value of surface area coating because.

In the processing, the black oxide layer is very easy to be created after rolling, binding, welding or fabricated surface warmth treatment, to get rid of the oxide layer, there are two reliable methods:

- Sandblasting: the main method is to spray mini glass beads to remove the black oxide layer externally.

- Chemical treatment: make use of a pollution-free pickling passivation paste and a cleansing remedy with inorganic ingredients at area temperature level without poisoning to wash, to recover the natural shade of stainless steel.

Mirror finish: apply different polishing techniques to achieve the specular radiance according to the complexity of stainless steel items and various demands.

- Mechanical polishing: excellent levelness, brilliant, high labour strength, severe pollution, hard to procedure complex components, reduced gloss, high investment, as well as expense. The gloss of the whole product is not constant, and the long-term time is not long.

- Chemical polishing: much less investment, complex parts can be polished, high performance, quick speed, not enough illumination, brightening fluid needs to be heated, there is gas overflow, and airflow equipment is needed, appropriate for complicated products with reduced brightness requirements. Tiny set handling is a lot more cost-efficient.

- Electrochemical polishing: to achieve mirror lustre, lasting upkeep, stable procedure, much less contamination, affordable, large single investment, ideal for complex parts, outfitted with tooling and also auxiliary electrodes. The process is simple as well as stable to operate, which can be commonly utilized.

Coloured finish: add colours to the stainless-steel surface, boosts the range of styles, and also enhances the wear resistance and rust resistance of items.

- Chemical oxidation: use colour with chemical oxidation in a certain option, consisting of dichromate, combined sodium salt, vulcanization, acid oxidation, as well as alkaline oxidation.

- Electrochemical: electrochemical oxidation in a detailed solution.

- Oxidation colouring by ion deposition: put the stainless steel work surface in the vacuum layer equipment for vacuum cleaner dissipation plating. Ideal for automation.

- High-temperature oxidation: immerse the work surface in a specific molten salt with certain parameters, to ensure that the work surface creates an oxide movie of a particular density, and offers a variety of colours.

- Vapour-phase thermal cracking: facility, less made use of.

Tips for Stainless-steel CNC Machining

Select the right tool material

- High-speed steel (HSS) or cemented carbide devices can be made use of for stainless-steel machining.

- Tungsten HSS can be helpful for their good abrasion resistance and also red firmness.

- M42 can be used as CNC milling cutters.

- If the devices are prone to edge cracking, utilize a tougher quality, if devices are simple to shed, use a greater red solidity grade, if the tools are using, utilize an extra wear-resistant quality.

Concrete carbides can be made use of for higher speed as well as higher feed.

Set up parameters in an appropriate range

Usually, the advised SFM is in between 100-350 for machining stainless steel components, with chip tons ranging in between 0.0005″ for a 1/8″ end mill as much as.006″ for a 1″ end mill.

Select proper coolant

The first thing is to locate a dependable coolant supplier, after that pick the very best coolant according to the product residential properties, application, and coolant kinds. The coolant can influence device wear, chip elimination, surface rate, feed and finish, deterioration resistance and also even more. Individuals who buy the coolant demand to aware of each type and function to make sure typical manufacturing.

Machines

The machine ought to be of excellent quality, extremely robust and rigid, as the stainless-steel is outstanding difficult steel.

Machines must not be excessively shaken in the maker bed, drives and also gearboxes.

Prevent the device out of the toolbox

The distance between the cutter tip and also toolbox assistance must be as short as possible.