Guide to Polish Titanium Parts

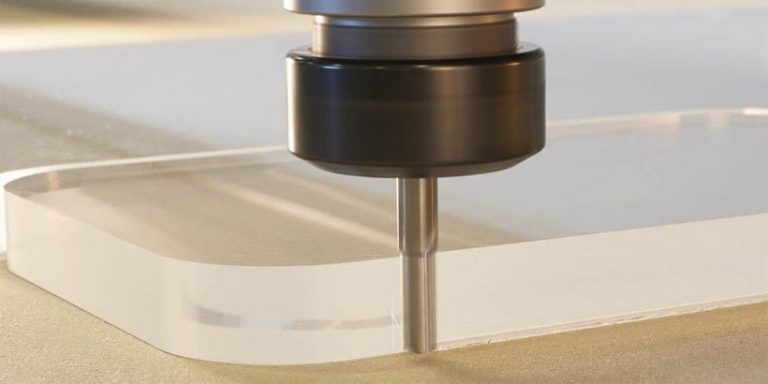

Titanium is a lightweight metal and also CNC machining titanium components are usually used in the medical & dental, fashion jewellery, aerospace and electronics industry, the titanium products will certainly shed their sparkle and also generate surface scratches after time. Titanium brightening solution can recover its initial metallic lustre as the mirror surface. Below we bring some techniques and also ideas for how to polish and clean titanium components.

How to Polish Titanium Components to Mirror Finish?

Polishing CNC machined titanium is simple yet it requires persistence. Before brightening, there are various other actions you need to take. For instance, if you are going to polish a titanium sheet or eliminate scratches, you must use numerous sandpapers to do the titanium fining sand step by step, such as 220 grit sandpaper, 400 grit sandpaper, 800 grit sandpaper. If you are going to brighten your titanium ring, get rid of all tidy as well as unclean it extensively, you can spray some cleaners on the surface freely, wipe it with a dry tidy towel in circular activities.

Just how to clean the titanium parts?

- Fill up a container or dish with cosy water (according to the quantity of your titanium part), place your titanium product in the container and also guarantee it’s totally submerged in water, including a small amount of mild soap. Soap can be changed with ammonia cleaner, jewellery cleaning solution or glass cleaner. Chlorine or bleach is not permitted.

- Soak titanium in the service for concerning 5 minutes.

- Take the titanium product out of the container as well as rinse it with clean water to leave it all cleaner.

- Take a dry soft towel or cotton cloth and gently try the titanium. But do not scrub tinted titanium elements.

Here are the steps for polishing titanium:

- Take a polishing pad as well as place it on the hook, a pad which is still affixed to a drill.

- Take a tidy, soft towel location them a little polish on it, make use of the towel to massage the titanium components or sheet till as dark as possible.

- Clean away any kind of spare gloss with an additional towel.

- Take your towel spray with a bit of water till perspires after that take the clear sealer place it on the towel, kind of rub it right into the titanium sheet till as dark as feasible.

- Wait for it to completely dry after that clean it away with an additional towel out of all the metals.

Various Titanium Polishing Service

Based on the requirements and also applications, the approaches and also tools made use of in titanium buffing and polishing will be differing, basic intros for polishing of different degrees are as below.

- Rough polishing: utilize a unique hemp wheel or wool wheel of titanium alloy as well as special titanium wax to polish titanium parts to attain a smooth surface. Focus on the polishing force and direction.

- Medium polishing: make use of the special polishing rough cloth wheel or great wool wheel of titanium alloy and also the unique sprucing up wax of titanium alloy to polish, remove the capillaries left by the rough polishing, until the item surface has light brightness.

- Fine polishing: make use of a unique cotton wheel for titanium alloy as well as finishing polishing wax for titanium alloy to make titanium alloy products reach high illumination. There are likewise some slight towel capillaries on the surface of the titanium product.

- Mirror polishing: use titanium alloy unique bleached cotton cloth wheel as well as titanium alloy unique mirror polishing wax to get rid of the slight cloth veins on the metal surface.

Please note that the above operations need expert polishing competent to satisfy the polishing requirements, mainly presents in the polishing force, speed, direction and various other details. DEK only offers titanium polishing service for your CNC machined components, but additionally sandblasting, anodize, paint, powder covering, passivation and more metal finishing services are offered.