Guide to precision machining affects medical devices

One of the most essential sectors that advantage from accuracy machining is the clinical industry. Many clinical products we use currently would certainly be difficult if there is no accurate machining.

Machining Meeting the Tightest Tolerances

The medical industry calls for safety and also great accuracy. Precision machining assists to acquire specific measurements for surgical devices.

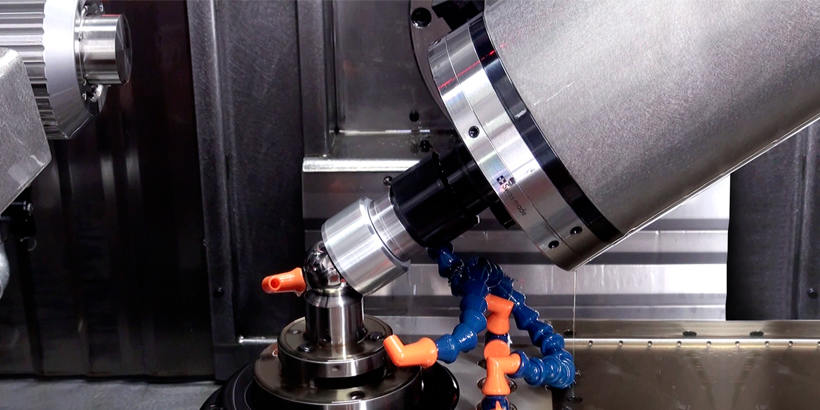

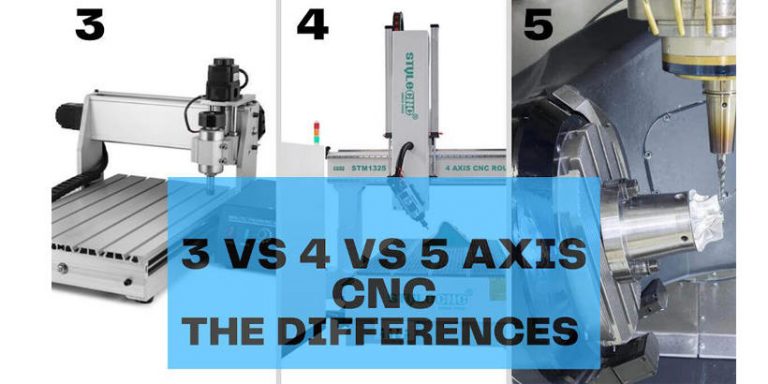

A few years back, it was difficult for machining made complex components that are made use of for lasers or robotics in the surgical area. Accessibility to machining can facilitate to have much more discoveries and developments which may result in clinical advancements. These devices require precise as well as extremely small components which only can be produced by CNC and also EDM machining tools.

These devices are used for the best surgical treatment, even for mind surgery or blood vessels. The smallest variance might be fatal. Machining can manufacture specific and also exact tools which are entirely reliable and risk-free.

Material Choices

Materials utilized in medical settings call for rigorous criteria for toughness, safety, non-reactiveness with our bodies as well as capability to be sanitized. Joint replacements are typically made from clinical stainless steel or metal due to their irreplaceable toughness, durability and also performance.

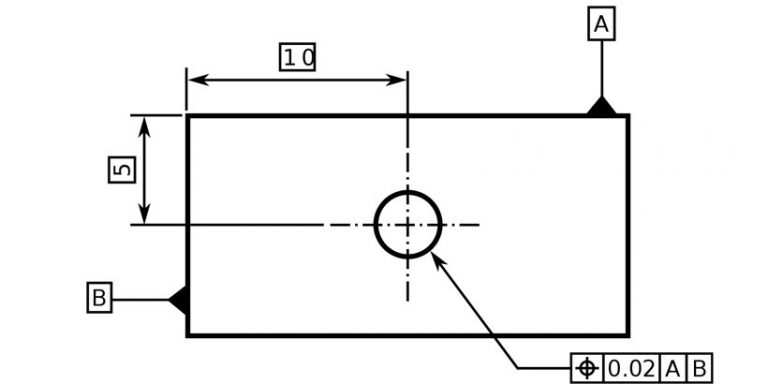

Precision machining makes these materials right into difficult sizes and shapes made use of for the specific clinical location. Some of these components are embedded into people, so they require to meet tight tolerances as well as have extremely smooth surfaces so regarding eliminating burrs or striations.

EDM, as well as CNC preciseness machining, is excellent for machining smooth and precise components, even if the material is extremely difficult.

Customized Devices for the Individual

Some medical devices can be personalized for people by precision machining. This is particularly vital for prosthetic gadgets like fabricated knees as well as limbs that should match the person. Precision machining can meet this need. Customized components are not only simple however additionally cost-effective by CNC machining. Components can be rapid as well as precisely manufacture after being inputted to the computer controls. Precision machining has actually progressed the clinical sector and is an integral part in the long run.