Why do thin-walled parts deform?

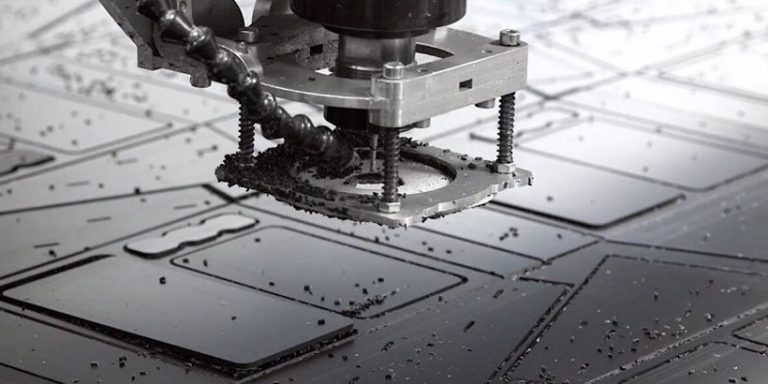

It’s tough to make thin-walled components by CNC turning since they are easy to be warped due to their inadequate strength and strength. We are going to clarify exactly how to boost thin-walled components made by CNC turning based on our experience. We can work on the securing of thin-walled components, cutting devices and also criteria choices, and so on.

Options of cutting specifications

When the parts with slim wall surfaces are machined with high precision, the symmetrical procedure is commonly embraced to balance the stress on the family member’s 2 sides and also reach a steady state. The part will be smooth once it is machined. The stress and anxiety will certainly shed balance and also the component will be transformed when there is much back cutting in a process.

Harsh machining, semi-fine machining as well as fine machining ought to be separated for thin-walled components which need high precision. Separation of roughing, semi-fine, and also fine machining will certainly stay clear of all sorts of deformation brought on by roughing such as elastic deformation brought on by securing force, thermal contortion triggered by reducing warmth as well as contortion caused by the distribution of interior tension when roughing.

The rear feed and feed are often bigger in the roughing machining. The back feed is typically 0.2 to 0.5 mm/r and also the feed is usually zero.1-0.2 mm/r or probably smaller. The reducing rate is 6-120 m/min. The cutting rate should certainly be high yet within a standard.

Options of cutting tools

It often tends to provide a method to the tool under the activity of radial pressure, impacting the hole’s accuracy. Boost the cutter bar as much as feasible when the thin arm component is machined.

Options of cutting fluid

Picking the cutting liquid reasonably can lower friction in the cutting method and also increase air conditioning problems, resulting in minimizing the cutting force, cutting power and temperature level, cutting device wear, and also boosting the high quality of machining surface areas. The cutting fluid for great machining is principally lubricated to improve the surface precision and roughness of the component and also for that reason it’s great to make use of severe pressure cutting oil or ionic cutting fluids.

Force

The work surface is easy to be warped under the securing pressure because of the thin wall, impacting the dimensional as well as form precision of the work surface.

Heat

Cutting heat can make thermal deformation as well as the size of the workpiece hard to be regulated because the workpiece is thinner.

Vibration

Vibration and also deformation can easily occur under the action of cutting force, particularly radial reducing force, affecting dimension precision and surface roughness of the work surface.

Affordable choices of clamping approaches

If the thin-walled parts are machined by the regular clamping method, great deformation will certainly take place as well as machining accuracy can’t be assured. Include extra assistance to reinforce the rigidity of the part if necessary.

Nonetheless, this strategy is restricted in the application as well as can create product waste. We can likewise enhance the securing indicate alleviate the contortion of the part. We can make use of special claws, fluid plastic self-facility chuck, or open-change ring clamp.

Summary

It’s tough to make thin-walled components by CNC turning because they are very easy to be flawed due to their bad strength as well as strength. We are going to clarify exactly how to improve thin-walled parts made by CNC turning based on our experience. We can function on the securing of thin-walled parts, reducing tools as well as specifications choices, and so on.

As well as The cutting fluid for fine machining is primarily lubed to increase the surface area precision as well as the roughness of the part as well as consequently it’s terrific to make use of severe pressure cutting oil or ionic cutting liquids.

It’s tough to assure the high quality of the component since of the excellent deformation triggered by reducing pressure and reducing warmth. Quality requirements of parts with thin walls can be assured by adopting the right securing method, complementary assistance, and progressed procedure strategy and also selecting appropriate device angle and cutting specifications.