Overview to Cutting Speeds and Feeds

Proper cutting speeds, as well as feed setting, are the basis of efficient procedure on CNC machines. This post, allow allows discovery speeds and also feeds definition, selection, computation as well as even more. Check out just how to establish cutting speed and also feed rate.

What are Speeds and also Feeds?

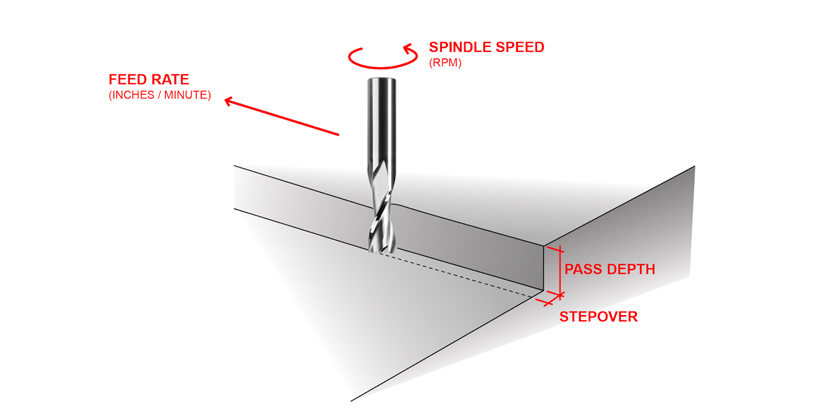

Speeds and feeds describe 2 different rates- cutting speed and feed rate in machining, yet they have a mixed effect on the reducing procedure, establishing the price of product removal, surface area finish, and power needs.

Cutting speed, also called surface area rate, is the loved one speed in between the cutting device and also the surface of the workpiece is being cut. The feed price is the loved one rate at which the cutter is advanced along the workpiece, or defined as the range the device takes a trip during one spindle transformation.

How to Figure Out Cutting Rate?

Cutting speed might also be specified as the rate at the part surface area, that is, just how quickly the material passes the cutting edge of the tool. For various operations, the meaning of surface might vary. In drilling and also milling, the surface area is the outside size of the device. Subsequently, as well as boring, the surface can be specified on either side of the deepness of cut (the beginning surface area or end surface area). Reducing speeds are shared in feet per min (royal) or meters per min (metric).

The material to be machined and cutting tool materials will certainly have a large impact on the calculation of the cutting rate. The deepness of the cut and the feed price will certainly also affect the speed, but not as great as the part hardness. If the types of material and machining conditions are transformed, the optimal reducing rate will be different. The softer the material of the workpiece, the higher the reducing rate, when the reducing tool material is stronger, the cutting speed increases.

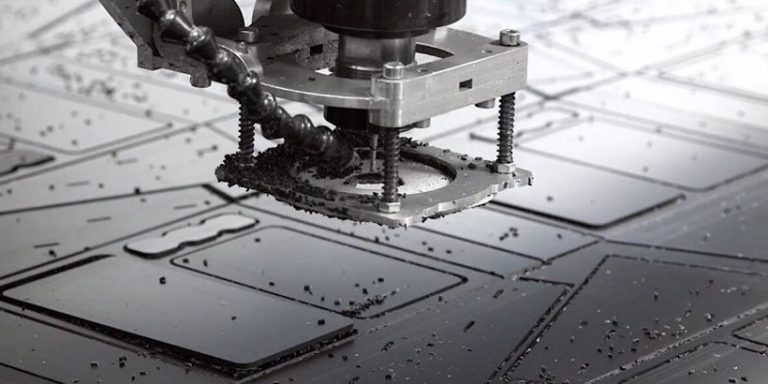

On a rotary tool like a drill bit for milling cutter, cutting speed amounts to how fast its periphery spins relative to the stock secured to the worktable, it coincides with the tools made use of on turrets, except their reducing rates are determined by just how quick the rotary material pass the edge of the turning device.

Just How to Identify Feed Rate on Lathe

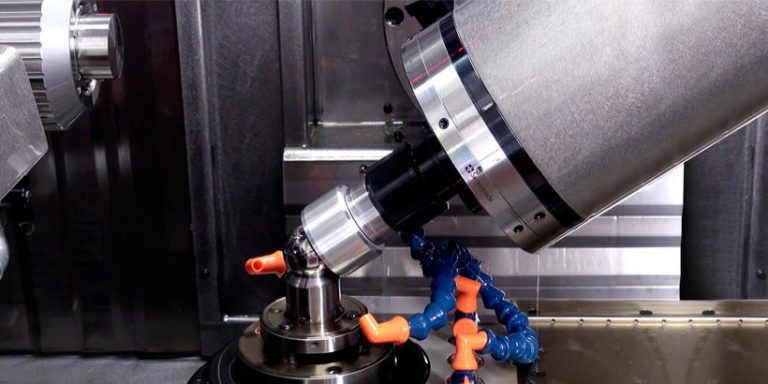

The feed of a lathe is determined by the speed of the lead screw or feed rod. The speed is managed by the change gears in the fast change transmission.

How Do You Calculate Cutting Speed as well as Feed?

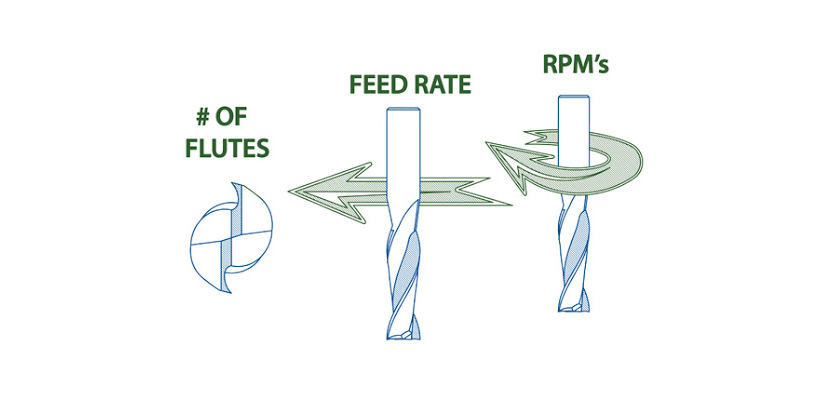

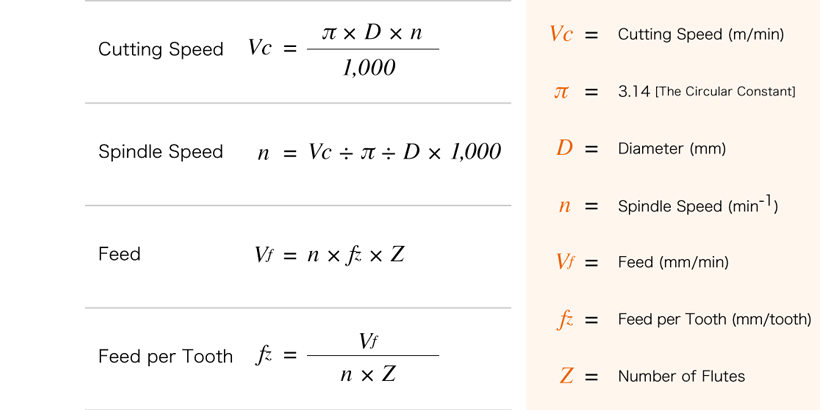

When computing the cutting speed in meters per minute, the spindle speed of the machine (n) and the size of the component should be known. When calculating the feed rate, pin rate, feed per tooth and the number of grooves ought to be recognized.

Calculator:

- Milling Speed and Feed Calculator

- Turning Speed and also Feed Calculator

- Drilling Speed and also Feed Calculator

Cutting Speed as well as Feed Rate Formula

Establishing Speeds on a Lathe Machine

Too high cutting speed will certainly make the tool much more conveniently damaged, while also reduced speed may be shed lots of time and reduce production efficiency. How to establish the cutting speed on a lathe?

- When speeds gauged in changes per min: transformed by tipped pulley-blocks or equipment bars.

- For belt-driven lathe: speeds obtained by altering flat belt and also back gear drive.

- For geared-head lathe: rates transformed by relocating rate levers into appropriate settings according to r/min graph attached to the headstock. Do not transform the speeds when the machine is running.