A summary of Aerospace Manufacturing

Aerospace is major assistance for the manufacturing industry. From advancement to finished components, aerospace manufacturing plays one of the most significant functions. What aerospace production innovations are made use of? Just how to discover the appropriate product for aerospace parts? In this post, we’ll present the common aerospace manufacturing methods, products, inspection as well as quality control.

Aerospace Production Innovation

Once the component design is accepted, the production can get going. The manufacturing process should be picked based on the production quantity as well as required preparation.

Additive production

Additive production (AM) refers to a process of creating a physical element from virtual three-dimensional computer system versions via including materials, usually in layers. Typical additive manufacturing modern technologies are consisting of 3D printing, sheet lamination, material extrusion, as well as much more. Aerospace is one of the pioneering sectors for additive manufacturing, the sector is identified by tiny set dimensions as well as manufacturer-specific adjustments. Additive manufacturing can be made use of to make one-of-a-kind geometries and lattice frameworks, which decrease weight, as well as help, dissipate warmth. It’s likewise an excellent strategy to develop semi-hollow get rid of innovative materials, decrease weight while maintaining strength, in accordance with the advancement fad of aerospace products. Additive production is made for aerospace components in low-volume, high-value manufacturing requirements.

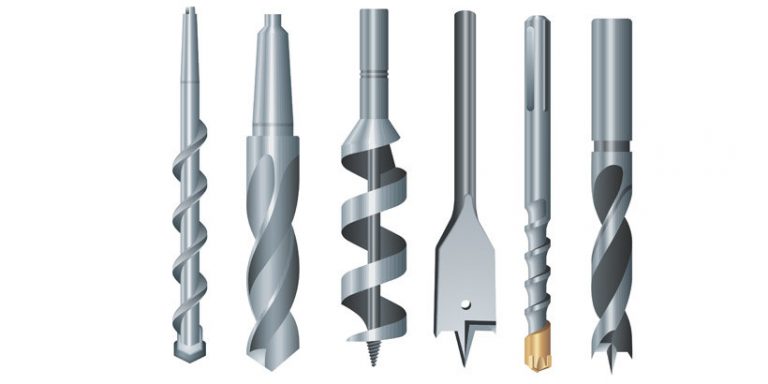

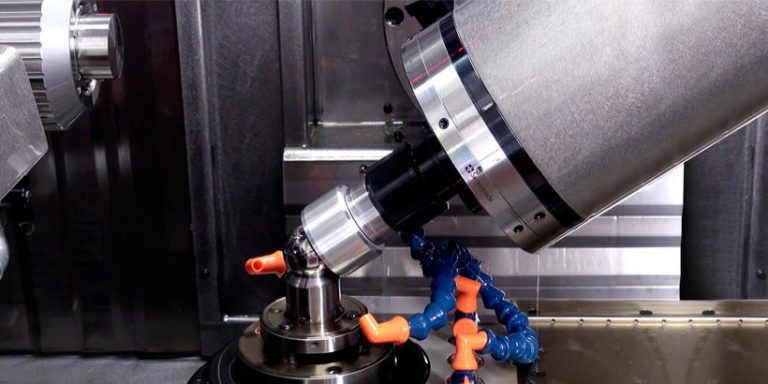

CNC Machining

The precision of planes is of utmost importance, from the body to little components, CNC machining services can create certain aerospace components as well as tools specifically. As an example, CNC machines can even create barely visible items in the engine inside or modify the wing of an airplane with extreme accuracy to ensure the wing can function efficiently. DEK is an acknowledged CNC producing business in aerospace item engineering and also machining services. We give a one-stop solution from quote, manufacturing, testing, completing, etc., to fulfill your one-of-a-kind and also difficult requirements. Trained specialists will check each CNC aerospace machining process to ensure top quality and also accuracy. CNC machining is a wonderful option when the finished components call for added finishing services, or for precise dimension and great surface area finish demands.

Material for Aerospace Parts

Based upon the unique attribute and also needs of airplane building and construction, complicated parts in light-weight material are the preferred selection, so it establishes which type of materials are suitable for the market. With the advancement of contemporary technology, more and more different materials showed up to create lighter, much more aerodynamic airplanes that can stand up to more extreme environmental conditions, such as brand-new compounds as well as alloys. Some popular aerospace products are listed here.

- Stainless steel: stainless-steel 17-4 PH is widely made use of in aerospace CNC machining or 3D printing because of its high stamina, excellent corrosion resistance, and great mechanical homes at temperature levels approximately 600 ° F.

- Aluminum: aluminum is an ideal choice for aeronautics real estate as well as brackets that sustain high packing due to it has high strength-to-weight ratio, in addition, it’s simple to equipment and cost-efficient. For virtually a century, the aerospace market counted on lightweight aluminum to make parts. The most common aluminum alloy made use of in aerospace is 7075 lightweight aluminum, which is as solid as steel, has good fatigue stamina, and also average machinability.

- Titanium: titanium is a mix of lightweight, high toughness, outstanding deterioration as well as temperature resistance. Business aircrafts today use a good deal more titanium than previously engineered airplanes. Titanium components and components are normally made use of to make fastening components, airframe as well as landing gear of airplanes like aircraft jet engines and also spacecraft, as well as engine components, include discs, blades, shafts, and cases. Titanium 6AL-4V alloy represents virtually 50% of all alloys used in aircraft. Capitalizing on the high weight-to-strength proportion, aerospace parts made from titanium take in less gas.

- Inconel: is a nickel-chromium superalloy typically utilized in 3D printing for rocket engine elements and other aerospace applications that require high-temperature resistance.

- Composite materials: including carbon fiber, glass, and aramid-reinforced epoxy, composite products are light-weight, which can be used to develop gas-effective aircraft. They can likewise withstand high resistance and also exhaustion, appropriate for making wings.

Aerospace Evaluation and also Quality Assurance

Evaluation is essential after the production procedure, specifically for aerospace components, when it involves the quality control of the aerospace industry, each tiny piece must be compliant with details high-quality requirements as well as qualification. The most vital accreditation for aerospace is AS9100D. AS9100D is a requirement for high quality in the aerospace sector adopted from ISO 9000/ISO 9001 criteria.

Just how to control the high quality throughout the production? Numerous quality control approaches can be used, such as in-situ monitoring for real-time comments and also modification during the part building, when the job is completed, the part can be based on either harmful or nondestructive screening with coordinate determining devices, as well as use touch probes or lasers, X-ray or various other scanning technologies to inspect the dimensional precision. Furthermore, full traceability of each batch of product and set of components can locate the source and also using the trajectory of all products, then the troubles can be located extra conveniently.