Guide to Rapid Prototyping Approaches

There are a number of different rapid prototyping approaches you can utilize for your product stage as well as functional demands. In this article, we detail 6 leading prototyping approaches for your factor to consider right here, CNC machining, polyurethane vacuum casting, and 3 plastic 3D printing methods: SLA, FDM and also Powder Bed Fusion.

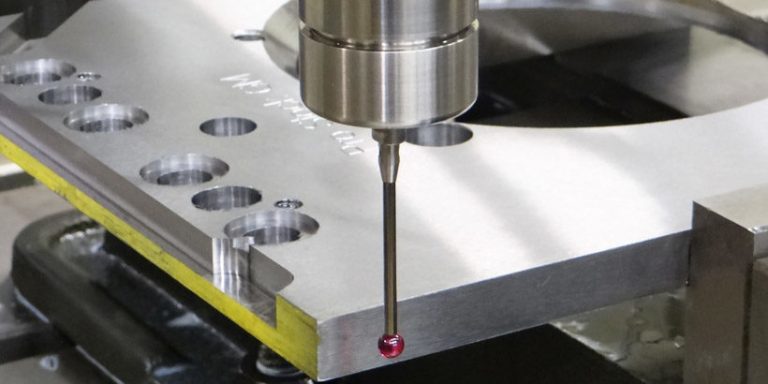

CNC Machining

Lots of people don’t realize that CNC machining is a suitable prototyping method for the ideal job. It’s rapid, very exact and very versatile since it works with virtually any kind of strong material, both plastic and metal. There are additionally no minimum amounts, so one component can be made equally as rapidly as one thousand.

You’ll want to take into consideration CNC machining if you require strong mechanical components that are totally practical and also have accurate resistances– generally, full-production high quality but in a restricted number. CNC machining is not ideal for deep tooth cavities or thin-walled boxes. For these shapes, you could intend to take into consideration thermoforming, 3D printing or vacuum cleaner casting instead.

Stereolithography or SLA

This was the extremely initial additive production procedure as well as it’s still improving constantly. It was launched readily in 1987. To make use of an SLA, you initially require to take your 3D CAD design as well as add supports to it. You after that slice that information into countless very slim layers. Utilizing a UV scanning laser, you then extract each layer one on top of an additional, curing the resin into a strong plastic 3D prototype.SLA is functional as well as rapid as well as there are lots of resins to pick from that offer various cosmetic and mechanical properties.

These are generally divided right into different qualities such as common, engineering or oral and also medical. You can even add glass fibres or aluminium powder for greater toughness. The surface coating is exceptional however bear in mind that, after printing, parts still require to be cleaned and after that treated a 2nd time to accomplish maximum toughness as well as stability. SLA components are additionally hygroscopic, which indicates they soak up moisture in time. That’s why we ought to store SLA components in sealed bags with offspring or in the dehumidification cupboards to maintain them dry.

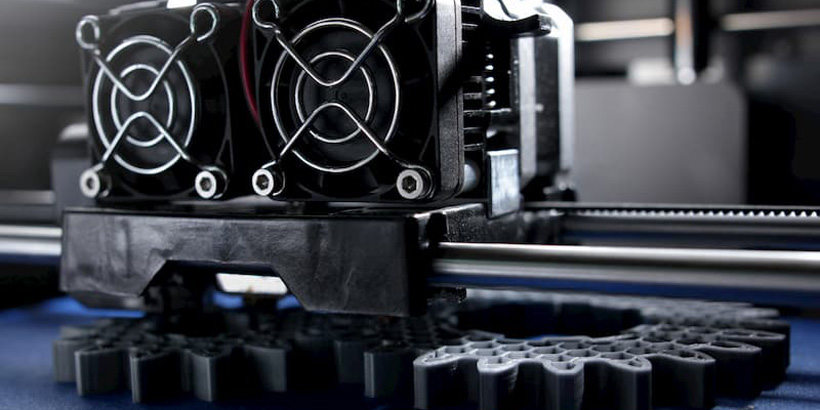

Fused Deposition Modeling or FDM

It uses filaments of common plastic like PLA or ABS or engineering resins such as PEEK and also Ultem. The filament is squeezed out through a warmed nozzle where it’s melted as well as this thaw is after that deposited layer upon layer to create the part. FDM is one of the least expensive additive production techniques and also is most prominent with residence enthusiasts and tiny bureau.

For model designers, it’s typically very easy to find a neighbourhood manufacturer room or digital printing bureau that can assist you to print out your styles promptly as well as cheaply, but be mindful that the resolution is not fantastic so your components will likely need more finishing work.

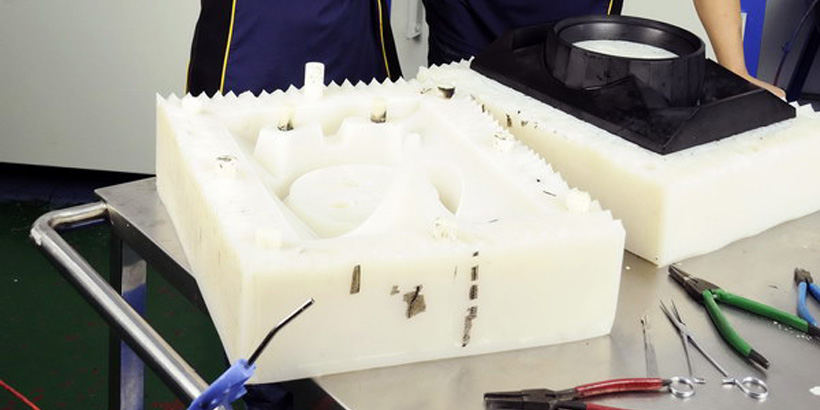

Polyurethane Vacuum Casting

Vacuum casting also called “cast urethane” in North America uses a solid master pattern to make a silicone rubber mold. The pattern can be made from any product but it’s often a plastic 3D printed component. In this procedure, the master pattern is put on hold in an empty spreading box. The package is then full of liquid silicone, and also after the silicone is treated it’s cut open as well as the pattern removed, leaving hollow dental caries that can currently be filled up with casting resin to make a duplicate of the original. If the master pattern has a gloss coating or a textured finish, this will be faithfully replicated on the surface of each spreading.

So require for second finishing oftentimes. You can additionally have clear parts or practically any kind of colour you prefer. Vacuum Casting is excellent for making near-production quality plastic components that look and also do like Plastic Injection Molding, yet without the need to invest in costly steel tools. Components can also be overmolded, as well as materials come in a variety of Shore solidities so you can make soft and also bendable items- something that you can’t do with CNC machining. The silicone molds last as much as about 20 copies approximately, making this a terrific means to produce enclosures and also various other semi-hollow kinds in small quantities, if demands are you can repaint, sand and machine them.

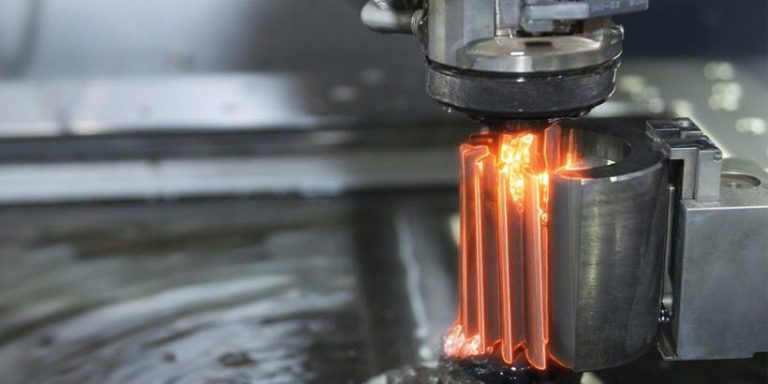

Selective Laser Melting (SLM)

SLM consists of making metal components with a high-powered laser utilized to weld and not just sinter, so producing a component that is totally thick. Nowadays, this approach is ending up being much more preferred not just for rapid prototyping, yet additionally for low volume production. High-quality lasers can make this process pricey, and also smaller sized scanning speeds can lead to longer production durations.

Powder Bed Fusion

There are two primary kinds of powder bed combination, Selecting Laser Sintering (SLS) and also Multi-Jet Fusion (MJF). They both utilize a closed chamber filled with a powdered substratum where a roller is utilized to smooth and also compress the top surface. Both systems mainly make use of Nylon. SLS integrates the Nylon with a laser, while MJF merges the Nylon with somewhat complex chemical agents as well as infrared power. At the end of the day, both systems will offer you a durable and also reasonably precise model for useful screening.

MJF often tends to be reduced price as the quantity rises and is for that reason rather better suited than SLS as a reduced quantity production process. There are several benefits to powder bed combination. There are a number of advantages to powder bed fusion. First, parts are self-supporting so additional structures are not required. Second, the whole develop volume of the chamber can be made use of for maximum effectiveness. And with SLS, approximately 75% of the powder from previous builds can be blended with virgin powder to save on basic material costs.