Guide to 5-Axis CNC Machine

With the growth of machine tools, numerous tools have been applied in modern manufacturing. To solve the issues of intricate shape processing, low efficiency as well as even more, 5-axis machining shows its benefits. Here we’ll discuss what is 5-axis CNC machine, its RTCP feature and also the distinction between 3-axis as well as 5-axis CNC machining.

What is 5-Axis CNC Machine?

To recognize just how does 5-axis CNC machining works, initially, you ought to understand the machine. In the mechanical style of a 5-axis machining facility, the device maker is constantly dedicated to creating new movement mode to satisfy greater demands.

Typical kinds of 5-axis CNC machines:

- Rotary table + pivoting spindle head

- Double rotary table

- Double pivoting spindle head

- Rotary table + table trunnion

RTCP in 5-Axis CNC Machining Center

RTCP (Rotated Tool Center Point), additionally referred to as TCPM 、 TCPC or RPCP, describes the function of keeping rotary axes at a continuous angle in-between tool and surface to be machined. In 5-axis machining, the extra activity of the tool factor is created because of the rotating activity when adhering to the device point course as well as the angle in between the device and the workpiece. The control point of the CNC system is typically not coincident with the device point, so the CNC system needs to instantly fix the control point to make certain that the tool point relocates according to the provided trajectory.

Pros of 5-Axis Machining

3-axis CNC devices are much more typical in the CNC producing industry, including upright, horizontal as well as gantry types, compared to 3-axis machining, what are the benefits of 5-axis CNC machining?

Keep the optimum reducing state of the device and enhance the cutting conditions

In the 3-axis machining, when the reducing device moves to the top or the side of the workpiece, the cutting state slowly comes to be worse. While 5-axis machine tool can likewise avoid the case as well as obtain much better surface high quality.

Avoid the cutting tool disturbance successfully

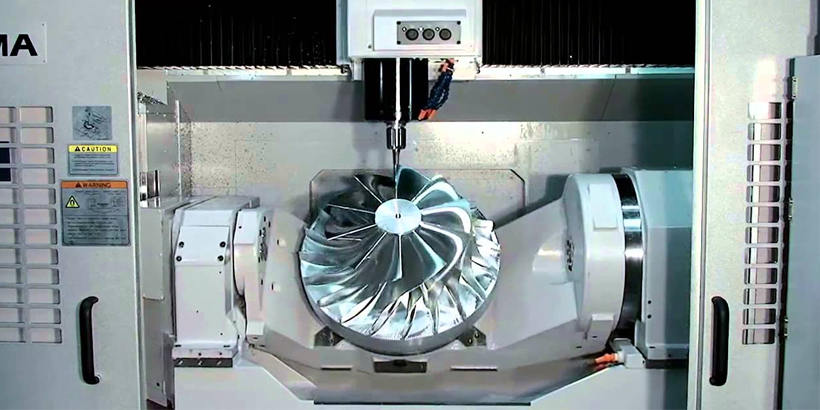

For the impeller, blade and black used in the aerospace field, the 3-axis CNC machine can not fulfil the technical requirements due to interference. The 5-axis machine tool can not only generate the preferred parts, yet additionally can make use of shorter tools for processing, improve the rigidity of the system, minimize the variety of devices, avoid the purchasing of unique tools, hence conserving the price of tools.

Decrease the quantity of clamping, total 5 side processing in one clamping

5-axis machining facility can do 5-axis side edge machining, 5-axis polyhedron handling and 5-axis pipe processing. In addition, it can decrease information conversion and enhance machining accuracy.

Enhance processing high quality and also efficiency

The five-axis machine tool can embrace the cutter side edge to cut, as well as the machining efficiency is higher. Due to the reducing of the process chain and the reduction of the tools amounts, the number of fixtures, the protected location of the workshop and also the price of devices upkeep are likewise lowered. This implies 5-axis CNC machining permits the CNC service business to provide higher efficiency of CNC machined parts with reduced cost.

Simplify production management

The 5-axis CNC machine substantially reduces the manufacturing procedure chain and also streamlines the manufacturing monitoring and organizing, specifically offers in facility parts machining.

Shorten R & D cycle of new products

In aerospace, auto and various other applications, there are some brand-new products and mould and mildews have complicated forms and high accuracy needs. The 5-axis CNC machining center with high adaptability, high accuracy, high combination as well as complete machining capacity can solve the issue, substantially shorten the R & D cycle and also boost the success opportunity of the brand-new product.