Guide to Aluminum Injection Molding

Injection molding is a manufacturing process made use of to generate models and also genuine products. It is effective and reliable as it permits the production of complicated product components with much better top quality and also yields. injection molding process widely relies on style and materials utilized in far better production. As a result, suppliers looking for less complex mold processes that allow for better items at a reduced price favour making use of aluminum injection molding.

Conventional injection molding process/steel injection molding procedure certainly creates durable items. In this short article, we will certainly go over aluminum injection molding, its drawbacks, advantages, and also its features.

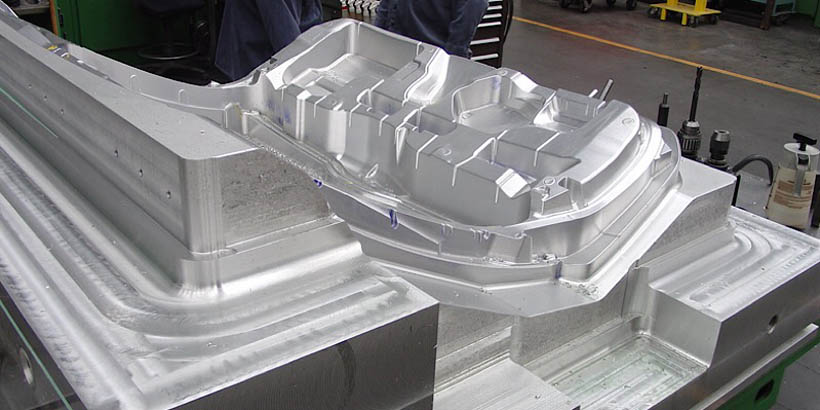

What is Aluminum Injection Molding?

Aluminum injection molding is an ingenious strategy based upon injection molding made use of to produce components (either prototypes/real items) with aluminum tooling. It is a perfect option for steel injection molding in quick prototyping and has broad fostering in automotive, aviation, and industrial processes.

Since it guarantees simple manufacturing of complicated products with marginal components, Aluminum injection molding is excellent. It ensures secure items with regular frameworks, high precision, and smooth surfaces. This arises from its buildings such as its capability to properly move warmth from the mold as well as assurance quicker product formation.

Attributes of Aluminum Tooling

Aluminum serves in tooling because of its lots of buildings, which aid in producing low-volume injection molds at a practical cost. Of its attributes, below are the crucial ones that make it ideal in lightweight aluminum injection molding and also tooling generally.

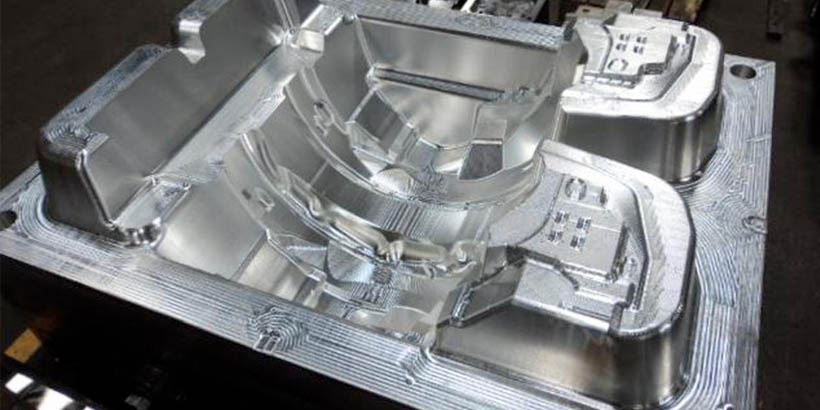

Metallic Properties

As for workpiece accuracy, a tool that has sufficient mechanical strength, as well as rigidness, is needed. Aluminum has solid metal characters, which preserves its strength and also strength to a certain level. It is likewise ductile making it the ideal material to utilize tooling.

A device needs to be strong enough throughout the manufacturing procedure. In aluminum injection molding, the proper option of reducing specifications, qualities, and geometries will likewise cause a more effective aluminum molding process. Consequently, aluminum utilized in tooling will certainly raise performance while reducing the price per element proportion.

Thermal Expansion and Cooling rate

Aluminum has a high coefficient of thermal growth. After heating to the right temperature, it can conveniently cool down which makes production fast.

This makes it a crucial product in the item manufacturing process that needs fast as well as reliable production. It additionally makes it perfect for the injection molding procedure.

Pros of Aluminum injection Molding

Lead

Aluminum injection molding guarantees a quicker path for the manufacturing of items. Steel injection molding can take months from making the mold to realizing the final product. Nevertheless, aluminum plastic injection mold and mildews only need days to produce mold, prototypes as well as make end products.

Machining Time

Aluminum plastic injection molds dissipate warm much faster than steel mold. Therefore, they can heat up as well as cool down a lot more swiftly. During injection molding, the cooling time accounts for the total cycle of the molding procedure. Consequently, choosing an aluminum molding procedure enables a shorter cycle, which converts right into the faster production of parts.

Expense

Aluminum injection mold cost is lower compared to steel in manufacturing an injection mold. The general worth and also ROI of a mold can depend dramatically on the mold usage. Nevertheless, the initial tool investment for aluminum is much less if all other elements are equal.

Great For Low Volumes

For low-volume set manufacturing of components, aluminum plastic injection molds supply much better value. This is due to their dependability in providing lower upfront price and also produces reputable components in thousands.

Better Products

One of the largest reasons for defects partly such as sink marks, spaces, as well as burn marks is non-uniform heating & cooling. The exceptional warmth dissipation characteristics of light weight aluminum plastic injection mold give an advantage of enabling the mold to warm and also cool rapidly and also evenly, therefore reducing the number of defective components and turns down.

Easy Repair and also Alteration

Because of steel’s extreme hardness, harmed or flawed steel mold might confirm extremely challenging and also expensive to fix. Usually, a brand-new mold is the only service. Aluminum plastic injection molds are from softer materials, and their design is separable and straightforward. This function makes it very easy to modify and repair in case of an error in the aluminium-plastic injection molds.

Cons of Aluminum Injection Molding

Restricted Surface Finish

Aluminum plastic injection molds provide minimal surface finishes contrasted to steel molds because of their low thickness. The high density of steel allows for numerous appearance selections and customized coatings by adding steel inserts.

Fewer Products

Aluminum injection molding can not hold up against the extreme temperature and also stress associated with injection molding processes for extensive periods. Consequently, they are not ideal for high and long-term volumes of part production.

Durability

Aluminum plastic injection molds appropriate for smaller component runs. Steel molds are more durable as they are corrosion-resistant, wear-resistant, and thermally stable. This permits the production of more items.

Engineers can replicate the same durability of steel by nickel-plating or annealing aluminum mold design. It would certainly raise aluminum injection mold cost which will negate the expense benefit connected with aluminum injection molding.

Complexity

Engineers can not enhance aluminum mold style in case of a requirement to make alterations as a result of the capability of molded parts to impact the mold. Steel molds can be toughened via heat treatment to handle developed materials of varying density.

Flash On Component

Flashing is the development of the excess product on a mold because of damaged cavities that no more fit snugly. After several thousand production cycles, aluminum plastic injection mold will wear as well as have non-conformities, resulting in flashing in the item.

The Design of Aluminum Injection Molding

The aluminum mold layout is an essential step in the item production design process. This is since it identifies the sturdiness of products and also the performance of the mold.

When making an aluminum mold design, Below are practices that a design expert must consider.

Guarantee Uniform Wall Thickness

On the one hand, thinner sections in a aluminum mold design tend to cool and also solidify initially. On the other hand, dense locations function as tanks that feed the lighter cells as they harden and cool.

Despite this, most components have varying cross-sections and also have a tendency to ice up faster than thicker parts. Feed paths must be such that they consider the solidification in both the thin and thick sections.

Doing this ensures the thickness part constant, simplifies the aluminum molding process, and also permits modern solidification to happen promptly.

Make Provision for Feasible Modifications

Throughout aluminum mold style, it is advantageous that your style consists of treatment for prospective modifications down the line. Although this may raise aluminum injection mold cost, it might confirm affordability later when improvement is required.

Making alterations without producing capabilities for such at the beginning start is possible. In most cases, it involves sacrificing the tool.

Keep In Mind of Component Details

When creating aluminum plastic injection molds, rather than sharp edges in the design, usage fillets. The existence of sharp corners in the treatment may considerably vary in shrinking of the generated component, bring about breaking or long-term defect.

Usage Inserts

Inserts of different materials and different shapes such as brass thread inserts can be included into aluminum mold style to enhance the resilience of the mold and also deal extra-hard surfaces where required.

Usage Suitable Alloys

Silicon is the most suitable component employed as an alloy in developing aluminum plastic injection molds. This results from its high specific heat ability, i.e., it maintains warm better than aluminum.

Silicon is not the only ideal alloy. Any alloy used need to have a brief freezing variety as it aids to advertise solid mechanical homes in products.

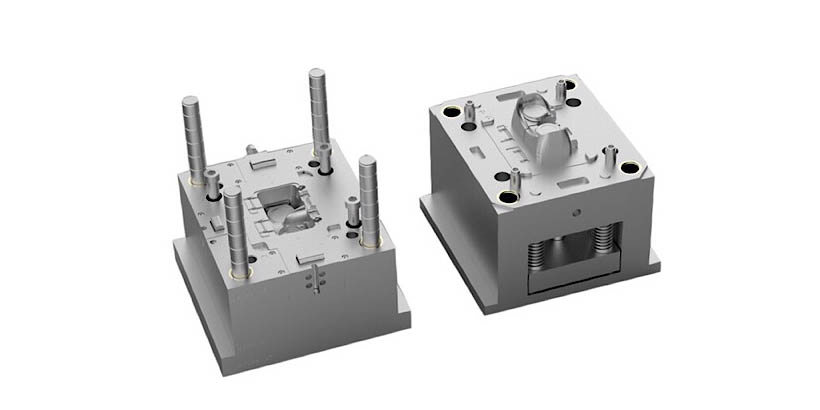

Differences between Aluminum injection Molding and Steel Injection Molding

Conventional injection molding depends on steel injection mold to produce a multitude of parts. Nonetheless, steel molding possesses specific constraints. There is a need for an alternative procedure like the aluminum molding procedure.

Based on various functions, there are lots of differences between aluminum injection mold and steel plastic injection mold. This goes above the products made use of in making them (Aluminum and also Steel) as well as is a lot more based a lot more on their applications, styles, and also attributes.

Below are a couple of considerable differences between aluminum plastic injection mold and also steel plastic injection mold:

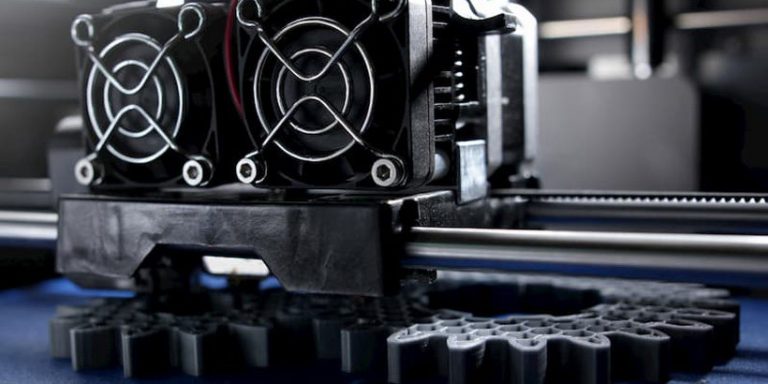

Turn-around Time

Aluminum plastic injection mold and mildews are manufactured using aluminum product by the CNC machining procedure. In some cases, producers use an Electric Discharge Machining (EDM) when cavities have to have sharp edges. A regular aluminum tooth cavity is made in concerning 10-15 days as the process calls for just mechanical techniques. There is no requirement for special production devices or thermal processing is needed.

Steel injection mold additionally comes from the exact same procedure. Due to steel’s hardness, it calls for special production devices and also goes through thermal handling to enhance its mold life.

Manufacturing Time

Manufacturing time is the time taken from the injection of polymer to the ejection of the end product. It is necessary to consider the batch item production process and it relies on the material of the mold, temperature level, and stress.

Aluminum injection mold is not solid sufficient to endure extreme pressure and temperature. As a result, the production time for aluminium-plastic injection mold is normally within 40– 70 seconds. Steel injection molds can endure high-temperature levels as well as stress far better than aluminum plastic injection molds as well as require just a couple of secs to generate parts.

Flexibility

Steel molds are not flexible as their hardness is due to the warmth therapy after the layout of important parts of the mold and mildew. Nonetheless, compared to steel injection molding, aluminum injection molding originates from softer products.

Its layout is such that it permits the creation of its mold components independently, which permits less complicated elimination to readjust models.

Mold Robustness

Mold robustness refers to the variety of components a mold can make before it becomes also corroded or worn out. This element is hugely depending on the design as well as the genetic make-up of the mold.

Steel injection mold is hard considering that their manufacturing process includes heat therapy. They also have a couple of joints, which makes them rigid and durable. Thus, steel injection molds can produce numerous components.

Nonetheless, Aluminum plastic injection mold originates from aluminum which, compared to steel, is a soft product. For that reason, it has lesser mold effectiveness than steel injection mold. Alloys made from aluminum are strong and also can guarantee a set of up to 5000 parts.

To sum up

The failing of an aluminum injection molding layout is frequently due to a poor style or poor tooling methods, alongside a damaged aluminum alloy choice. This article introduced aluminum injection molding, its characteristics, and some designing tips. Aluminum injection molding can seem frustrating. With the right company with a heightened knowledge of the process and an excellent record of handling product development, you can guarantee better product formation.

We at DEK give enhanced aluminum injection molding styles in product production. Speak with our support team for making advice. If you currently have CAD data, upload it now to get an instant quote for your design.