Guide to Injection Molding Ejector Pins

The introduction of ejector pins injection molding to producing processes has actually resulted in automated operations, boosted production speed, as well as made certain extra efficient products. It has also improved consistency in the designs of products.

In spite of the enhancement of manufacturing procedures by injection molding, there are, nevertheless, several flaws in its style that demand to be maximized. This is to guarantee much better and also a lot more efficient items.

Hence, this write-up looks at ejector pins injection molding, and how to enhance its layout to have extra reliable products.

What Are Injection Molding Ejector Pins?

Ejector pins are important in creating components. They are an integral part of the ejection system in mold, which establishes the final outcome of products in an injection molding process.

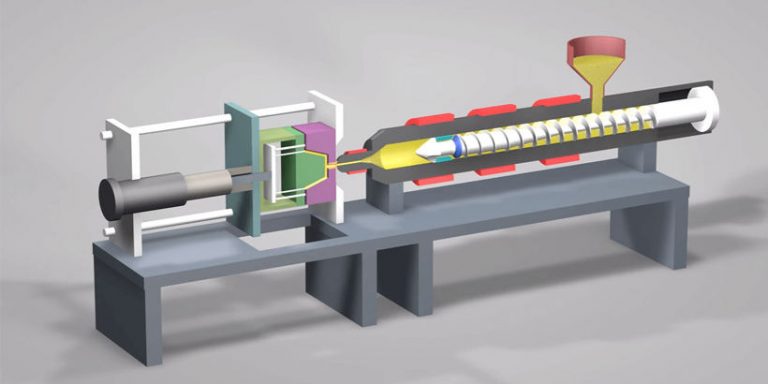

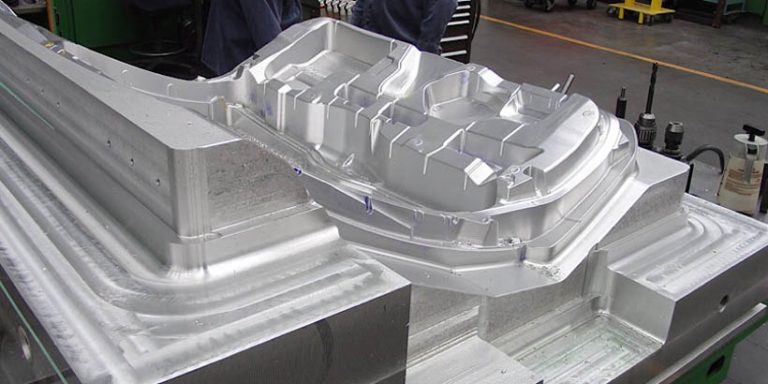

Injection molding is a manufacturing process that includes infusing liquified plastic in a steel mold to think the form of the mold. As a result, ejector pins injection molding includes the removal of finished parts from the die molds. The steel mold is made from two parts: An as well as B sides. Upon cooling of the molten material in the mold, both parts of the metal mold are separated to permit the removal of the solid plastic. Injection mold is constructed such that when they are opened, the A-side fifty per cent is lifted, leaving the created part as well as the B-side.

Ejector pins are located on the B-side half of a mold, where they press the formed dismantle of the mold. The pin mark of an ejector mold is typically imprinted on finished products as a dent.

Common Issues and Solutions

Injection molding utilizing ejector pins includes some problems. Below are the feasible problems, as well as the essential remedies.

Ejector Pin Marks

These are “damages” left on the part by ejector pins during removal from the mold. This pin mark can lead to the fracturing of the products while in use. Therefore, it is essential to develop an ejection system in mold to prevent ejector pin marks.

- Organize the ejector pins such that the force of ejection throughout the component is constant.

- Place the ejector pins on tough parts such as metal columns, ribs, and also inserts to avoid ejector pin marks flaw.

- Design the placement of the ejector pins on the flat surface area of the part rather than on inclines.

Jetting

Jetting happens as a result of tiny gateway size, or there is rapid speed injection of liquified product right into the mold resulting in a distorted form.

This can be fixed by:

- Boosting the dimension of the gate.

- Controlling the flow of the molten product to the mold.

Breaks

The major reason for the breaking of ejector pins is the distinction in the call for pressure to expel the part from the mold and the toughness of the pin.

Ejection of parts from the mold needs force. Often the needed force exceeds the toughness of the pin as a result of its need of support size, thereby bring about breaking.

The most reliable way to remedy ejector pin breaks is to employ large quantities of ejector pins with bigger diameters. In this manner, the force required has also distributed throughout various pins, thereby reducing breakage.

Kinds Of Ejector Pins

There are many sorts of ejector pins used in item production. Below are the commonest types you will locate excellent for the process.

Case Hardened Ejector Pins

They are additionally called Nitride H13 pins, are much harder pins than the through difficult pins, and also are suitable for die casting ejection system in mold. Case solidified pins are nitrated to 65– 70 HRC as well as can withstand temperatures over 200 ° C.

Through-Hard Ejector Pins

These ejector pins are heat-treated to make sure uniformity in the solidity through the diameter of the pin. Through-hard pins can stand up to working temperatures up to 200 ° C, and also it is primarily appropriate for plastic ejection system in mold.

Black Ejector Pins

Producers established these ejector pins because of the inability of the Nitride H13 pins to be used in working temperatures above 600 ° C. The black ejector pin is coated with a black surface therapy which permits it to be self-lubricating as well as stand up to heats approximately 1000 ° C. It is a costly ejector pin as well as appropriate for metal ejection system in mold for autos.

Other Kinds of Ejectors

While they might not be common with lots of machinists, there are likewise other types of ejectors. Below are some instances.

Ejector Plates

In an ejection system in mold, ejector plates work alongside the ejector pins. It holds the head of the pins to avoid them from appearing throughout the ejector pins injection molding procedure.

Ejector Sleeves

These are just hollow ejector pins. It contains a hard-surface sleeve pin with a core as well as an opening pin that suits the hole. The holes in the ejector sleeves are to safeguard the pin and direct.

Ejector Blocks

They have a lubricating hollow groove and also applied to the surface of slim items that need a high surface finish but would be ruined by an ejector pin marks flaw.

They limit ejector pin marks and also applicable for usage on the surface of items with high warpage.

Injection Molding Style Factors To Consider

An injection mold style must be such that it functions as intended. An error in the style may cause the reduction or splitting of part, which can verify too pricey or also entrusting to treat.

The need to perform a well-structured style is essential, and also there are particular elements to take into consideration.

Uniform Wall Thickness

When a liquified product is poured into a mold with uniform wall thickness, it flows openly without limitation, filling out the wall’s dental caries as well as thinking of its defined shape.

Non-uniform mold walls will certainly lead to the air conditioning of the thinner area of the molten product. As the thicker area cools, it will certainly result in the diminishing of the material, stress concentration, and eventually splitting during elimination.

If your design does not allow uniform wall surface thickness, it can be remedied by coring and adding gussets.

( Coring is a procedure of eliminating the molten plastic from the vast location to make sure uniformity along the wall. Gussets are support frameworks that you contribute to the wall surface as reinforcements to reduce the wall surface’s thickness).

Minimize Undercuts

Undercuts are extending features in the mold design that obstruct the removal of either side of the mold. Undercuts are required as well as inescapable in a mold design as they stop the part from direct ejection from the mold.

Nevertheless, undercuts can be treated by developing interlocks or latches that allow for simple elimination or setting up. As much as feasible, the design group have to keep the variety of undercuts in an ejection system in mold at a minimum.

Nature of material

The type of material utilized must depend upon the feature of the item.

Some materials are thick, some are versatile, while others are breakable or hard. The sort of material chosen would certainly determine what objective the part is for as well as its design.

While you can enlarge some materials it is also feasible to flex them right into shapes. Likewise, you need to think about these before picking the sort of material.

Create Draft Angles

Draft angle is a slant in shape that is put on both sides of an injection mold. This mild distortion in the form of the mold permits the very easy removal of the plastic from the mold.

Draft mold should be present to give resistance versus friction while eliminating the part from the mold. Allowing even more draft angles would certainly ensure the easy launch of parts from the ejection system in mold.

The absence of draft angles would result in big ejector pin marks on the component throughout removal and scratches on the wall of the mold.

Make Certain Round Edges

Having rounded corners on the inside as well as beyond the component has several benefits. It decreases the stress and anxiety focus and protects against the part from cracking.

Sharp corners limit the circulation of molten plastic in the die, and upon cooling down the plastic draws versus the sharp edges and also is hard to get rid of.

Round-edged parts are easy to generate, a lot more cost-effective, and also enable better development and also removal of items.

Gate Locations

Gates are the access factors of the molten plastic to the mold. Upon air conditioning of the part, the gate leaves a pin mark, which is most times, still visible also after dent elimination.

The style group can make use of an edge entrance to treat this, where the resulting damages would certainly be less obvious. The liquified material is likewise injectable with an expansion situated on the ejection pin.

Upon cooling the component, the ejector pin can push off the resulting pin mark from the gate throughout the removal of the part from the mold.

To sum up

Design specialists can not neglect the value of ejector pins in the injection molding process. This is due to the fact that the created item in the mold depends upon the effectiveness of the ejector pins to prevent the ejector pin marks problem.

It is essential to rely on a business with an understanding of Layout for Production, exactly how to use ejector pin and also an excellent document of dealing with ejector pins injection molding layout.

We at DEK can guarantee optimized layouts for your ejector pins injection molding procedure. Consult our assistance group for producing advice and if you currently have CAD data it stays a little action. Post it now to obtain an instant quote for your layout.