Guide to Aluminum used for machining

Aluminium is the 3rd most common component in the Earth’s crust after oxygen as well as silicon. It has excellent rust resistance and also low thickness, which makes it crucial in the transport, aerospace, electrical and structure markets. It can likewise be utilized for household things. 25% of aluminium is cast and also the other is functioned or alloy aluminium.

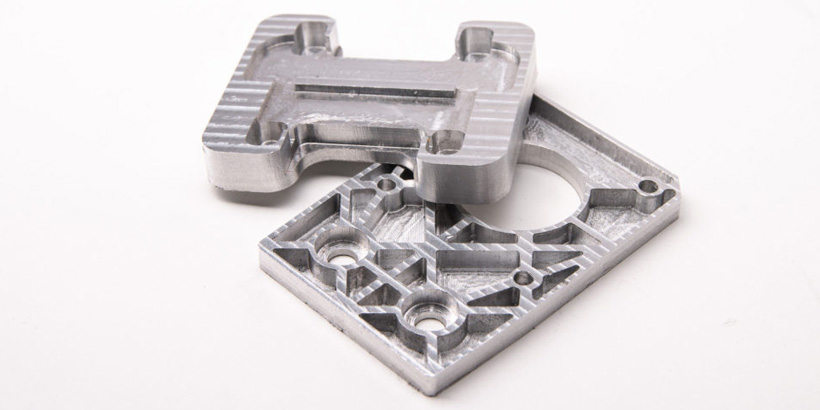

Cast Aluminum MIC6, 319, 356, 383

Aluminium 319 is used for cylinder heads as well as transmission real estates, 356 for cylindrical tube heads as well as 383 for engine blocks. Components that are made by high-pressure pass away casting don’t require heat therapy. Aluminium passes away spreading is extremely strong and also more affordable than wrought aluminium.

Pros

- Cast aluminium can conduct heat and electricity well.

- Cast aluminium can acquire lighter and stiffer styles.

- Cast aluminium can be totally reused.

- Cast aluminium has great rust resistance.

Cons

- Cast aluminium contracts and also increases even more than steel when the temperature level modifications.

- Cast aluminium does not stand up to deformation.

- Cast aluminium does not manage fatigue.

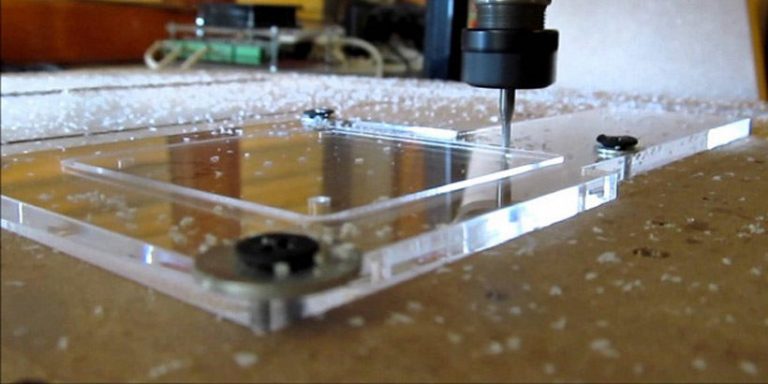

Wrought aluminium 6061, 7050, 7075

The elastic modulus of aluminium alloys has to do with 70 GPa and that is about 1/3 of steel. Aluminium alloys can have better contortion under a given lot. There are some aluminium alloys that have much better tensile stamina than those of typical steels. Usually, lighter and stiffer styles can be gotten from aluminium. Huge diameter tubes are adopted by aluminium bike frames in order to have far better toughness with lighter weight. Aluminium alloys have lower exhaustion stamina contrasted with steel.

Various sort of alloys

- Silicon is contributed to 4000 collections.

- Magnesium is included in the 5000 collections. 5000 collection are wonderful for the marine field due to their excellent deterioration resistance.

- Silicon, as well as magnesium, are included in the 6000 series, which makes the 6000 collections machinable and weldable. 6160 is probably one of the most generally used aluminium alloys.

- Zinc is included in the 7000 collections, which make it be precipitation hardened to the greatest toughness.

- Aspects in the 8000 collections are not discovered in other collection. 8000 series are commonly made use of in places like aerospace where high stamina to weight ratio is essential.

- 1000 series are virtually pure aluminium.

- Copper is included in the 2000 series. Nevertheless, the 2000 collection can quickly be influenced by tension corrosion cracking and they are replaced by 7000 collections for brand-new styles.

- Manganese is added to the 3000 series.

Pros

- Aluminium can conduct power and also warm.

- Aluminium can acquire stiffer and also lighter styles than steel.

- Aluminium can be reused.

- Aluminium has excellent rust resistance.

Cons

- Aluminium contracts and also broaden more than steels when the temperature modifications.

- Aluminium does not resist deformation.

- Aluminium does not handle fatigue.