Guide to CNC Plastic Machining

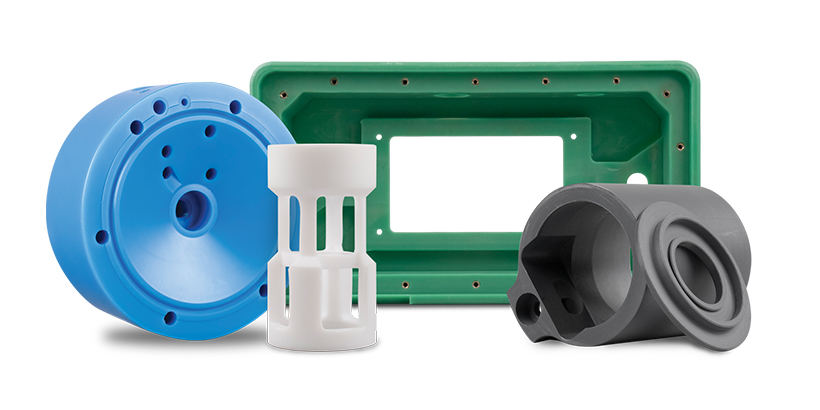

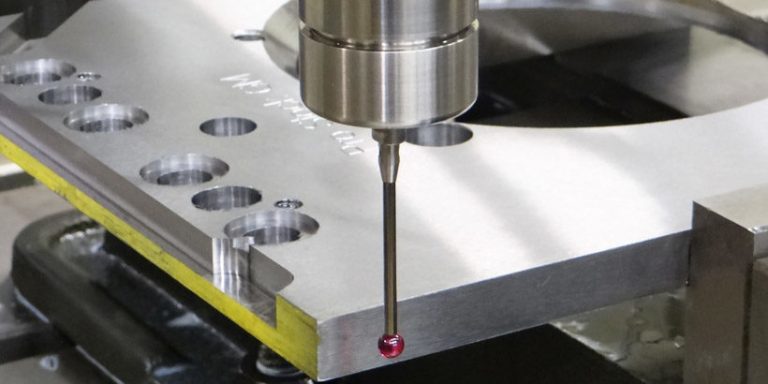

Nowadays, plastic items can be discovered in varied applications and also valuable for different industrial concerns. CNC plastic machining gives a quick, effective, and economic way for modern-day plastic components making. The selection of plastic material is based upon their properties and also applications. Here we’ll find out about the usual uses of various types of plastic products readily available in CNC machining.

What is the Plastic?

Plastic is a reasonably affordable, light-weight, as well as long-lasting product that comes in different grades of polymers. While the production procedure embraced Computer Numerical Control is much faster and easier.

Whether you need a plastic prototype, a huge batch of personalized parts, complicated geometries, or other plastic items, DEK can give precision CNC machining services that deal with a range of plastic materials. Whether your selection of products is steel or plastic, our efficient programmers, machinists, designers, and qualified operators have the ability to employ correct processes and also maker tools to achieve the preferred performance.

All kinds of plastic applications

In CNC plastic machining, there are several choices for various requirements. CNC plastic parts can be used in aerospace, medical, oil as well as gas, and a lot more industries. Allow’s take a look at the common plastic materials for CNC machining and their uses, which is a reference when you pick a material for your project.

PEEK

PEEK (Polyether ether ketone) is a semi-crystalline, opaque, high-performance engineering thermoplastic, has exceptional tensile properties, outstanding creep resistance, reduced rubbing, great dimensional stability, great insulation residential properties, resistance to fluids, and also fantastic fatigue, as well as insoluble in all usual solvents. Popular applications of PEEK plastic are automotive parts like seals, washing machines, bearings, transmission components, air-conditioning systems, aerospace engine parts, aircraft exterior parts, convoluted tubes, oral tools, endoscopes, and dialyzers, coaxial port jacks made use of in hands-free telephone packages, surface-mounted cutting potentiometers, connector pins on under-sea atmosphere control devices, etc.

PC

PC (Polycarbonate) is a highly valuable engineering thermoplastic that has high openness, high strength, good heat resistance, high effect resistance. PC plastic appropriates utilized to make bullet-proof glass, safety glasses, sunroofs in autos, control panels, headlamp lenses, bumpers, body panels, CDs, DVDs, Blue Ray discs, electric insulator, LED screens, ATM, smartphone panels, infant alcohol consumption bottles, authorities riot equipment, swimming safety glasses, and also SCUBA diving masks, and so on.

PTFE (Teflon)

PTFE (Polytetrafluoroethylene), likewise called Teflon, is a flexible ivory-white and nontransparent plastic fluoropolymer, very versatile, chemical immune, thermal resistant, non-stick, and electrically resistant, and as its reduced friction, PTFE plastic is excellent for applications consisting of a non-stick layer for pans and other kitchenware, insulation of circuitry in aerospace and computer applications, lubricant, graft material in medical treatments, catheters finish, ordinary bearings, types of equipment, slide plates, seals, gaskets, bushings. etc. PTFE machining is popular for its high machinability.

POM (Acetal)

POM (Polyoxymethylene), likewise known as acetal, polyacetal, and also polyformaldehyde, an engineering polycarbonate has high rigidity, reduced friction, excellent wear resistance, reduced wetness absorption, good electric homes, as well as exceptional dimensional security. The regular applications of POM or acetal consisting of fuel rails, fuel supply device, control valves, cars lock, safety belt insurer, HAVC control panel handles, auto clip, and much more parts in the auto industry; pipeline combinings, shower head, water filters, pumps for commercial usages; gas storage tank, caps, and also pipes in durable goods; electronic units, bushings, bearings, equipment, and so on.

Nylon (Polyamide)

Nylon is remarkably strong as well as flexible, has excellent toughness as well as abrasion resistance, excellent thermal and chemical resistance, very easy to wash, and also dye. Nylon is frequently made use of to produce plastic fasteners and also machine parts, pots and pans, and also material, in addition to parachute covers, auto components, mechanical components, food, and also beverage sector.

ABS

ABS (Acrylonitrile Butadiene Styrene), different elements in ABS make it has excellent strength as well as stamina, likewise providing chemical and also thermal stability and shiny finish. Typical applications for ABS plastic are refrigeration elements, 3D structure materials, pipes & fittings, vacuum building and construction, key-board tricks, digital housing, lego playthings, customer products, parts of nebulizers, compressors, songs instruments, sports equipment, mixer, control board, and so on. Even more information for CNC ABS machining is offered on DEK.