Guide to Comparison of Stainless Steel

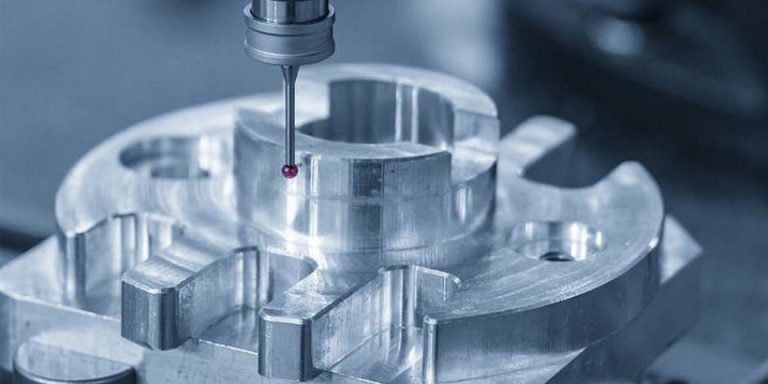

As a usual general-purpose metal, 304 stainless-steel is simple to be seen in our life as well as the manufacturing market. In this short article, we’ll compare the difference between stainless-steel 304 and other grades in composition, properties, expense, applications, and much more elements, want to assist you to comprehend more kinds of stainless-steel alloys and also essentials for machining 304 stainless steel.

What is 304 Stainless Steel?

304 Stainless steel is a usual sort of austenitic stainless-steel, additionally referred to as 18/8 stainless-steel. 304 stainless steel structure: at least 50% iron, have a maximum carbon content of 0.08%, and also includes approximately 18% chromium as well as 8% nickel. SS304 is widely used to make equipment and components needing good extensive performance (rust resistance and also formability), like market, car parts, home items, furnishings decor, agriculture, food, as well as the medical industry. The thickness of stainless steel 304 is 7.93 g/cm ³. Stainless steel CNC machining services on DEK associates with a wide variety of stainless steel qualities to make completed stainless-steel products with the finest quality.

Type 304 Stainless Steel Properties

The uses and also applications of stainless-steel machining components are often established by its homes and characteristics, which likewise influences the metalworking process on it.

- Great corrosion resistance, heat resistance, low-temperature stamina and mechanical properties

- Excellent stamping and also bending properties

- High machinability and also weldability

- Non-hardenable by heat therapy

- Resistance to 800 ℃ high temperature, as well as high toughness

- 304 stainless-steel modulus of elasticity: 193-200 GPa or 28000– 29000 ksi

- Thermal conductivity of stainless steel 304: 16.2 W/m-K or 112 BTU-in/hr-ft ²- ° F.

- A food quality stainless-steel, suitable for food processing, transport and storage space.

Stainless Steel Comparison

Comprehend the 304 stainless steel properties, we can roughly know what settings as well as applications it can be utilized in, while when you intend to choose the best product from all the stainless-steel qualities, you need to figure out what are the distinctions between them. Here we’ll compare SS304 with 316, 303, 201, 310, 430, 409 and also more, describing the structure, homes, cost and also utilizes. Select the right CNC machining stainless-steel material according to your requirements.

What is the difference between 304 and 316 Stainless-steel?

- Structure: 304 consists of 17.5% -19.5% chromium and 8% -10.5% nickel while 316 contains 16.5% -18.5% chromium, 10% -13% nickel and 2% -2.5% molybdenum.

- Properties: the greater molybdenum content leads to quality 316 obtaining increased corrosion resistance. Stainless steel 316 has a higher resistance to chemical attack and also oxidations than 304. 304 has higher formability than 316.

- Price: 304 steel is more affordable than 316.

What is the difference between 303 and also 304 Stainless-steel?

- Structure: stainless steel 303 has a minimal 17% Chromium, 8% nickel, and also 0.15% Sulfur/Selenium, while 304 stainless steel contains a minimum of 18% chromium and 8% nickel.

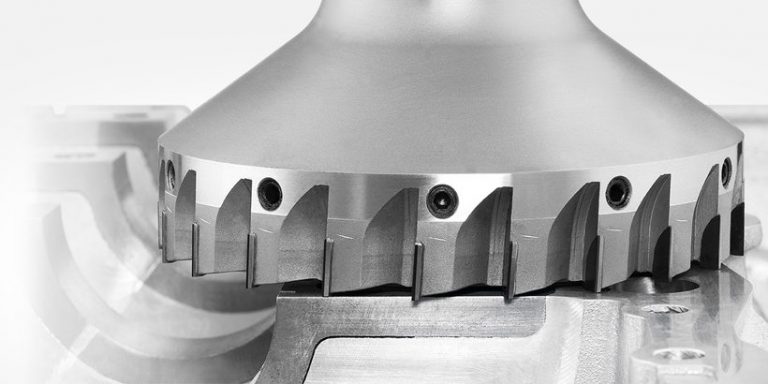

- Properties: the addition of sulfur a little lowers corrosion resistance yet raises machinability of 303 stainless-steel, it’s a free-machining quality of ss304. So 303 is a lot more machinable than 304, while 304 is extra weldable and has higher corrosion resistance.

- Cost: acquiring stainless steel 303 is a bit a lot more pricey.

- Application: 303-grade stainless-steel is better to be utilized for producing nuts, screws, aircraft gears, fittings, bushings, and so on 304-grade stainless steel is better for applications where aesthetic appeals, as well as tidiness, are vital, including architecture, food processing, piping, product packaging, etc.

What is the difference between 304 and 18/8 stainless steel?

304 stainless steel is part of the 18-8 household. What is an 18-8 stainless steel? 18/8 stainless steel, also called 18-8 stainless-steel as well as 18 8 stainless steel, refers to the 300 collections of stainless steel with 18% chromium and also 8% nickel material. The typical classifications include 301, 302, and also 304 stainless steel.

What is the distinction Between 304 and also 201 Stainless steel?

304 stainless-steel consists of more chromium, which provides it outstanding corrosion resistance. While Stainless steel kind 201 has a greater level of manganese. Stainless steel 201 is preferable for sectors that need higher durability at a lower expense as well as not fret about exposure to corrosive elements.

- 304 steel has higher corrosion as well as stamping efficiency than 201.

- SS304 has better strength.

- 201 grade is much easier to rust.

- Stainless steel 201 is less costly than 304.

- 201 stainless-steel looks darker than 304.

What is the Difference Between 310 Stainless Steel and 304 Stainless Steel?

- Structure: 310 kind has a higher chromium material (24-26%) vs 304 (10-20%), as well as nickel content( 19-22%) vs 304 (8-10.5%).

- 304 steel is mosting likely to be pretty ductile, and 310 is a bit harder.

- Stainless steel 310 has higher wear, hardenability and deterioration resistance than 304.

- Grade 310/310S is generally utilized in kilns, glowing tubes, tube hangers for oil refining and vapour boilers, coal gasifier interior elements, lead pots, thermowells, refractory anchor bolts, heaters, and so on.

What is the Difference Between 304H as well as 304L in Stainless Steel?

The primary difference between 304H as well as 304L is the per cent of carbon. The greater the carbon web content, the worse the rust resistance of the stainless steel quality, likewise differ in prices.

- 304L is ultra-low carbon steel stainless steel with carbon material around 0.03% or much less, while 304H includes carbon web content that is not less than 0.04%.

- The corrosion resistance of 304L is better than 304H theoretically. 304H is a lot more immune to sensitization than its 304L counterpart.

- 304H satisfy the high-temperature demands and also provides improved heat stamina when exposed to temperature levels exceeding 800 degrees Fahrenheit.

- The distinction in 304 stainless-steel yield strength and also 304L is a little higher, with SS304 having a 0.2% yield stamina of 42ksi (289 MPa) and also 304L having a 0.2% return strength of 35ksi (241 MPa).

What is the Difference In Between 430 Stainless Steel vs 304?

- Structure: stainless steel 430 contains no nickel, while 304 has an 8% to 10.5% nickel material.

- 430 stainless steel is magnetic and 304 is not.

- 304 stainless steel is more flexible and also weldable.

- SS304 sets during cold-working, while 430 does not.

- 430 quality stainless is a lot more machinable.

- The cost of 304 stainless-steel is more than 430.

- 304 has a lot more rust-resistant quality than 430.

- 304 is a lot easier to press and also draw.

What is the Difference In between 304 vs 409 Stainless-steel?

- Structure: 409 stainless-steel includes 10.5% -11.75% chromium and also 0.5% nickel, while 304 stainless steel has a chromium content of 18% -20% as well as nickel web content of 8% -10%. 409 stainless steel can be almost 90% iron. 304 stainless steel has a much lower concentration of iron.

- Because of the make-up difference, surface rust on 409 stainless-steel machined component is quicker, 304 is much more rust-resistant than 409 as well as has a much longer life span.

- 409-grade stainless steel does not polish along with 304.

- 409 steel is more suitable for bending and heat cycling. 304 stainless-steel hardness is more than 409.

- The expense of stainless steel 409 is lower.