Tips for Check & Investigate Precision Machined Parts

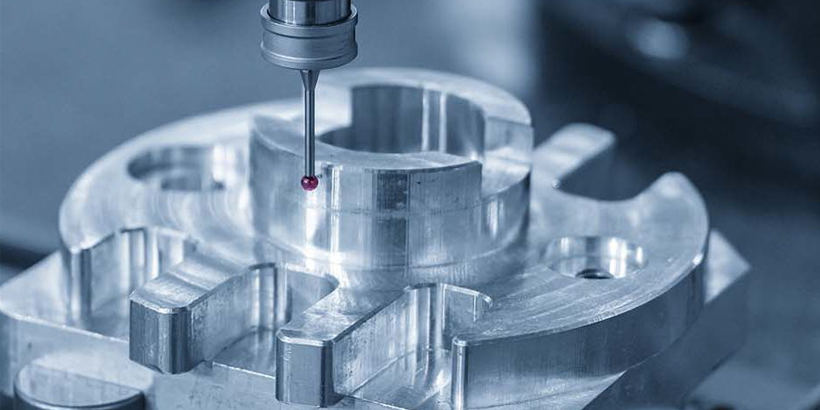

The precision machined parts should be evaluated after manufacturing, to take a look at if they are certified and precise. The precision components commonly have an intricate framework as well as special forms, which need to be gauged in several actions. DEK will introduce exactly how to evaluate and also check out the elements as well as precision CNC machining services.

7 Tips for Inspect Precision Machined Parts

- For huge quantity production, a simple limitation gauge can be utilized for assessment.

- For tiny batch manufacturing, make use of the micrometer to evaluate the dimensional accuracy of the CNC machined parts.

- For accurate components with big size and also high precision, we can utilize comparators.

- If there are high needs for the surface roughness, utilize the optical microscopes or shape chart. It is able to in addition use micrometers with V form iron somewhat.

- It is able to in addition use micrometers with V form iron somewhat.

- About the inconsistency from cylindrical forms, we can use a micrometer to measure the distinction between the max and minutes size of the identical axial phase.

- The evaluation of shared positional accuracy of one of the most important shaft always makes use of the facility opening on both ends of the shaft as information recommendation, gauging with micrometer scale on each bearing magazine.

DEK Accuracy CNC Machining

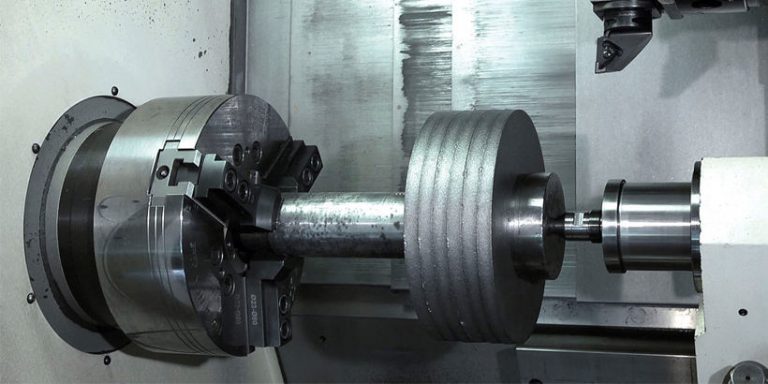

Accuracy element handling is a machining approach with high accuracy, high requirements of manufacturing machinery, and also process. In order to make certain the machining precision of the components, it’s far better to divide the rough machining and also ending up. DEK is a professional China precision components producer that supplies CNC machining services, CNC milling services, CNC turning services, and CNC milling-turning services.

We can collaborate with a choice of metal and plastic materials in various sectors with accuracy CNC machining, our software application assistance Car CAD, JPEG, PDF, STP, IGS, and most other documents formats, plus the advanced electronic system and also machines, skilled workers, as well as skilled engineering for examination, every one of these benefits allows us to able to take care of high quantity precision parts manufacturing of practically any kind of types based on the customized designs. Each detail will be inspected and verified strictly.

Precision Components Procedure Needs

- Establish a collection of reliable and also sensible operation rules and instructions in the usage and monitoring of CNC machine devices.

- In order to expand the service life of CNC devices, it’s essential to avoid direct sunlight and also various other radiant heat, as well moist area, and also area with excessive dirt as well as corrosive gas. The precision tools must be away from the gadgets with huge resonance, such as creating and cleaning tools.

- Operators need to have expert procedure abilities, consisting of experience with the equipment, understanding of precision machining, and knowledge with the qualities of machining materials, and so on