Guide to Yield Strength of Aluminum

Performance and also buildings are important recommendations when picking materials for an application, such as yield strength and tensile strength. The mechanical properties of aluminium alloys vary based on their mood, in this short article, we’ll introduce the yield strength interpretation and also contrast it with tensile strength.

What is the Yield Strength of Aluminum?

The yield strength is defined as the stress and anxiety at which an established amount of long-term contortion happens. When subjected to tension, a material undertakes contortion, yield strength explains the optimum quantity of stress and anxiety required to elastically flaw the product in a provided loading arrangement like tension and also compression.

This indicates the anxiety past yield strength, the deformation is recoverable and also any type of contortion that takes place because of the anxiety greater than the yield strength is irreversible. Yield strength is determined in N/m ² or pascals. Pressure hardening, stress rate, the temperature of the steel as well as hydrostatic pressure will impact the worth of yield strength.

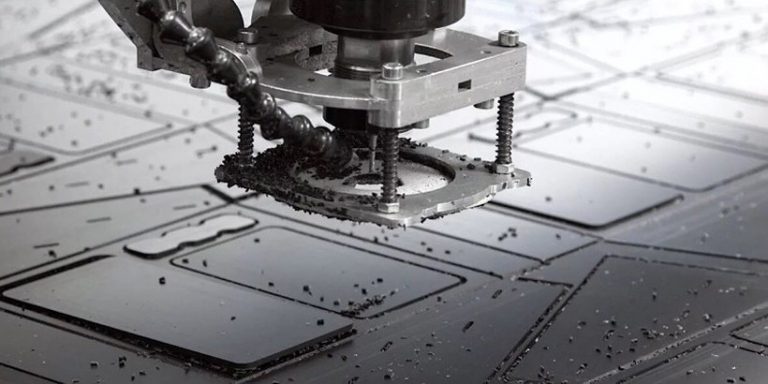

In other words, for example, with little force, the aluminium flaws plastically firstly, when you launch the anxiety, it can return to the initial shape; after that with more pressure, it deforms plastically, this is yield strength when you release the stress and anxiety, its form is permanently transformed; last, with a much greater force, it damages, this is best tensile strength. In CNC machining of aluminium, we must have a standard understanding of which problem the aluminium product can hold up against to ensure the procedure goes smoothly.

Distinction Between Yield Strength and Tensile Strength

Tensile strength, additionally referred to as supreme tensile strength, is specified as the maximum tensile tons a material can stand up to prior to crack. Tensile strength and yield strength are both vital mechanical properties when reviewing an aluminium alloy as well as can be established utilizing a tensile examination, what’s the primary distinction between yield toughness and tensile toughness?

- Yield strength is measured at the point of plastic contortion, while tensile strength is gauged at the point of fracture.

- Yield strength is normally used for pliable products, while tensile strength used for brittle materials.

- The yield strength is normally gotten to earlier than tensile strength. That is, for the very same material, yield strength is lower than tensile strength.

- The tensile strength of a product can be established properly, while yield strength needs to be estimated for many materials.