Guide to Plain Milling Machine

In this short article, we’ll find out about the plain milling machine representation and also the working concept of mills. As a key machining process, CNC milling can create various functions. From the introduction to every part of the milling machine, learn more about just how it’s working as well as what it is made up of.

Plain Milling

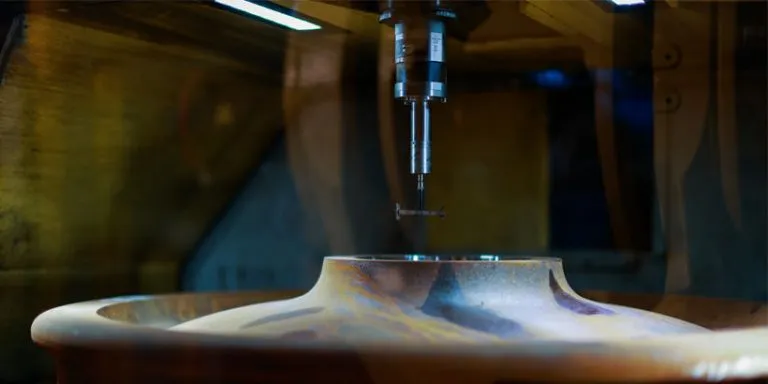

Plain milling, additionally called piece milling or surface milling, the process of milling a flat surface area with the axis of the cutting device parallel to the surface being machined. The rotating milling cutter does not provide a continual cut yet actions from one end of the workpiece to one more end.

The Basic Design of a Milling Machine

The building is the basis of learning about using a CNC milling machine. Plain milling is a typical kind of milling operation. Right here we bring the ordinary milling machine layout with the maker components and features, to aid newbies to enter into the working of milling machines.

- Base: serves as the foundation of the entire maker, supplies support and rigidness, in some cases made use of as a storage tank for the cutting fluids

- Column: the major supporting framework placed vertically on the base, includes all the driving mechanisms for the spindle and table feed, as well as overview methods to move the knee backward and forwards.

- Knee: an inflexible spreading placed on the front face of the column, slide along the guideways backward and forwards by elevating screw, which enables distance change in between the cutter and also parts, made use of to support the saddle, table, work surface, and clamping devices.

- Saddle: the intermediate component in between the knee as well as table, mounted on the guideway of the knee to sustain as well as carry the table, relocates transversely.

- Table: located on guideways in the saddle, with t-slots and also accurately finished leading surface to secure the workpiece as well as hold. It can move in 3 instructions: upright (up and down), cross (in or out), longitudinal (to and fro).

- Overarm: placed on the top of the column, acts as the assistance for the arbor.

- Arbor: can be fitted at any kind of location of the overarm, the expansion of the equipment pin, to hold and drive the milling cutters.

- Spindle: situated in the top part of the column, mounted with the milling cutter.

- Elevating screw: used to move the knee and also table up or down automatically or by hand.

The Functioning Principle of Milling Machine

There are several kinds of milling machines made use of in manufacturing, like horizontal milling machines, universal milling machines, vertical milling machines, planar milling machines, simplex milling machines, and also extra options for unique functions. Milling machines whose motion is computerized managed are CNC milling machines. The working of the general milling machine took on the subtractive manufacturing method of material removal.

The workpiece or space is fixed on the worktable of the milling machine, the relocating table regulates the workpiece feed versus the multi teeth cutter, which is mounted on a spindle and also rotating at broadband. When the cutting device is turning, with the motion of the milling part, the workpiece slowly approaches the cutter, after that the product will be removed from the surface area of the element to be machined up until the preferred shape is produced.