Nylon 6 and Nylon 66, Which one is better?

Nylon 6 and nylon 66 are some of the most usual nylon polyamide qualities that are commonly utilized in fabric as well as plastic sectors. As the variations of polyamide, they have many exact same qualities, however, the kind and also quantity of polymer chains in their chemical structure bring the distinction. In order to simplify the selection of these 2 plastic materials in design applications, here we offer the contrast between nylon 6 and nylon 66, to reveal the difference between PA 6 as well as PA 66.

Nylon 66

Nylon 66, also referred to as nylon 6-6, nylon 6/6, or nylon 6,6. Nylon 66 is an amorphous solid that has excellent abrasion resistance, high melting point, high tensile stamina, high dimensional security, high lubricity, resistance to hydrocarbons, as well as picture degradation, along with exceptionally balanced strength, ductility, and heat resistance. It is very resistant, water-proof in nature, and also slightly soluble in boiling water, difficult to color but possesses high colorfastness as well as not easy to fade.

Nylon 6

Nylon 6 or polycaprolactam is a semicrystalline polyamide, not like various other nylon plastics, it is not a condensation polymer. Nylon 6 fibers are basic in white, can be dyed to other shades, hard, wrinkle-proof as well as highly resistant to abrasion and chemicals, have high tensile toughness and also influence toughness, machinability, great flexibility, as well as appeal. It additionally supplies outstanding wear as well as abrasion resistance, long-term heat resistance, high flame-resistant grades (UL 94VO), as well as a high water absorption rate.

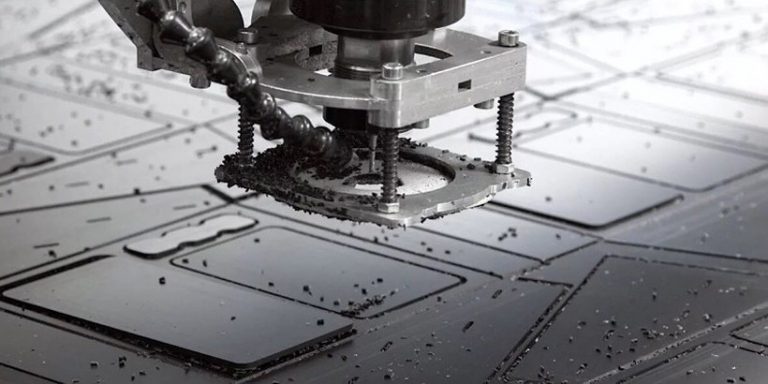

CNC Nylon Machining Providers

Nylon is a preferred engineering plastic product due to its adaptability, light-weight, resilience, and various other benefits. DEK is concentrated on CNC nylon machining based on innovative strategies (turning, milling, boring, completing, etc.) for different variants, consisting of nylon 6 machining as well as nylon 66 machining, to match for uses in various markets, such as house appliances, food handling tools, automotive, general objectives and more.