The Reason For Make Use Of Plastic CNC Machining

CNC machining is among one of the most efficient machining procedures, and also the reasons for this are not unlikely. Among such reasons is its capability to machine a wide variety of materials. An instance of such products is plastic. While plastic CNC machining may feel like a poor choice for machining, it is actually among the best choices.

This post is a must-read if you’ll like to understand how you can use plastic CNC machining in the production of numerous parts.

Benefits of Plastics in CNC Machining

Here are some benefits of using plastic CNC machining for your parts manufacturing:

Economical Process

For various other procedures like shot molding, you have to create mold and mildews that normally take up several resources as well as time. Plastic CNC machining does not involve such. The quantity spent for part production is somewhat less expensive than various other procedures.

Greater resistance to corrosion as well as chemicals

CNC machined plastic products have this advantage over steel components. Contrasted to steel components which can easily rust after expanded use, plastic components are a lot more immune.

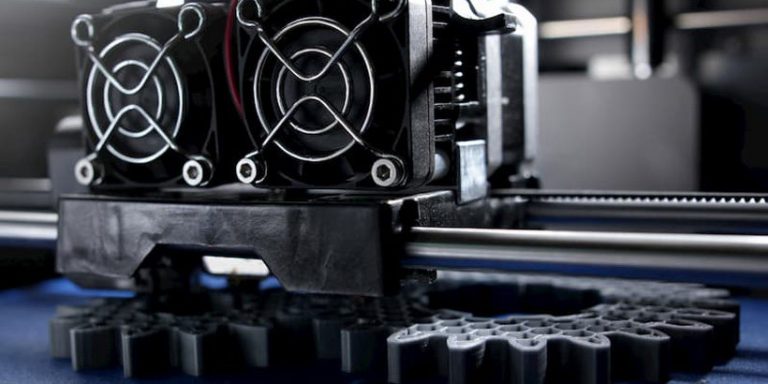

Fast Prototype Turn-around

Plastic CNC models are the most effective choice for anyone who needs a model to be made quickly. This is due to the fact that there’s no demand to make a mold. The procedure is reasonably faster, as well as the model will certainly have a shorter cycle time.

Hold Tighter Tolerances

For parts that require high resistance dimensions, plastic CNC machining is an outstanding selection for manufacturing. Due to the fact that it can suit tight tolerance measurements, this is. This is extremely essential for parts that will be utilized in high-precision industries.

Applications of Plastics in CNC Machining

Aerospace Industry

CNC plastic models are an exceptional way to examine if these parts fit for addition right into the aeroplane. Apart from plastic prototyping, aircraft components such as the tails, bodies, ventilation air ducts, etc, additionally, utilize plastics.

Electronic Industry

Plastic CNC machining has virtually infinite applications in the digital market. Because the industry includes a lot of items that involve the use of plastics, this is. Machinists make use of plastics in products like switches, electric insulation materials, mobile phones, etc.

Automotive Industry

With the machining of various high-performance plastics, the usage of plastics in cars has actually considerably boosted. Ranging from the auto’s outside to the framework, machinists use different plastics in making parts of automobiles. Plastic is a great source for prototyping new auto parts to be incorporated into vehicles.

Medical Industry

Using plastics for components manufacturing in numerous markets is a piece of cake for both machinists and customers alike. From its relatively inexpensive rate to reduce machining, plastic is a favourite for application in industries such as:

Because of the special buildings certain plastics possess, they are better suited for medical applications where safety and security and sterilization are critical. Some CNC plastics materials are an ideal fit for this process as they can withstand autoclaving numerous times without deterioration.

Military and Defense Industry

Plastic CNC machining also has a lot of applications in the army industry. Ranging from its usage in their communication tools to parts of their transportation lorries, plastic CNC machining is a vital process to the armed forces as well as the protection industry.

When to Take Into Consideration Plastic Machining for Manufacturing

Selecting the best production method could be an uphill struggle for clients sometimes. If you drop into any of these classifications, utilizing plastic CNC machining is a superb choice to make.

- When you have a tight budget plan.

- If you have a low manufacturing quantity.

- When you need a rapid item or model turn-around.

- If you just wish to make prototypes (that do not always need one more type of material).

You might also speak with your machining company concerning the compatibility of CNC plastic machining for your component production. At DEK, we offer professional opinions to our clients about exactly how their parts manufacturing can be enhanced.

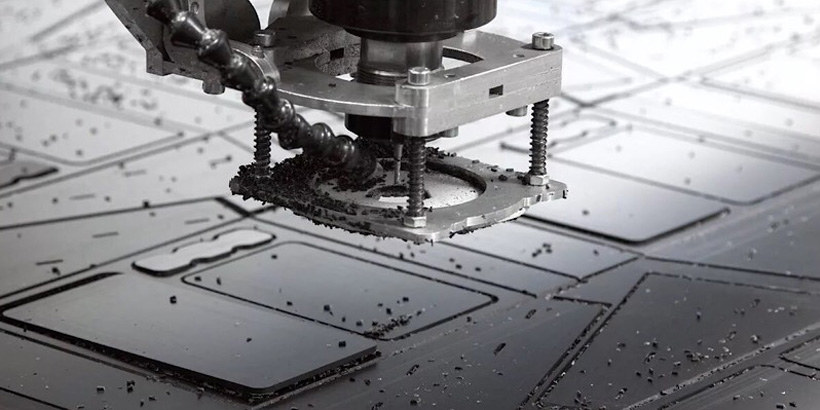

Just how to Create a Plastic Model with CNC Machining

The plastic prototyping process includes making use of plastics to make models. Prior to machinists began using CNC machining for prototype manufacturing, the steel used to be the best product for procedures. This is due to the fact that injection molding used to be the major plastic machining process before.

With injection molding, you’ll have to invest rather than the sum to make the mold. The machinist also has to be very cautious while making the mold. Because mistakes in the procedure can lead to additional fees that also include the job’s quantity.

Below are the procedures and pointers for plastic CNC machining:

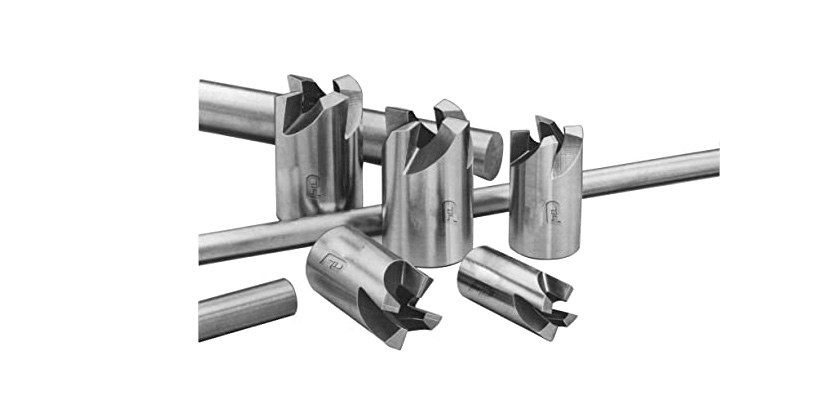

Tool selecting

Although plastic has actually various buildings contrasted to steel, the type of tools utilized on both coincide. It is only the force of cutting that varies. Instances of plastic machining devices used for plastic CNC models include:

- End Mills: They are one of the most preferred kinds of milling cutters, and also they are quite similar to drills as a result of their ability to reduce products axially. There are different variants of the CNC maker tool. They vary in the variety of grooves and also the various kinds of noses they have. Some might have up to eight flutes or even more. The types of noses consist of:

Flat: The flat-faced end mills is the general-purpose variant suitable for removing 2D features.

Ball nose: The ball-nose end mill appropriates for jobs like 3D shapes and contours.

Bull nose: This version has a level end and rounded sides and also is best for filleting and roughing.

- Ball Cutters: You can swiftly identify ball cutters due to their hemispherical cutting suggestion, which the cutter uses in making corner spans on perpendicular faces.

- Hollow Mills: This mill has a pipe shape and looks inverted in kind. Machinists use hollow mills to produce shapes like full points and develop span as a result of the mill’s cutting side, which you can discover on the internal part of the mill.

Material Selection

Machinists utilize different plastics in plastic CNC machining. Nevertheless, there are a few of them known for their outstanding qualities in plastic prototype machining. Examples consist of:

- ABS(Acrylonitrile Butadiene Styrene) includes different components which offer it preferable properties. It is a popular selection for machining amongst machinists as a result of its chemical as well as thermal stability to its great sturdiness and stamina. Machinists use ABS to create parts such as control board, pipelines, refrigeration elements, keyboard keys, and so on.

- PC (Polycarbonate) is an additional plastic that machinists utilize for plastic prototyping due to its properties. It is an extremely hard plastic that can hold up against hefty effect as well as high degrees of heat. Machinists use it for parts such as baby drinking containers, Blu Ray discs, swimming goggles, etc.

- POM (Polyoxymethylene), additionally known as Delrin, polyacetal, or acetal, is a design polycarbonate distinguished for its low dampness level of sensitivity, high resistance to chemicals, great electric conductivity, high toughness and toughness. Machinists make use of POM in the manufacturing of parts such as auto locks, auto clips, seatbelt adjuster, etc.

- Nylon (additionally understood as polyamide) is a general-purpose engineering material that has different grades. Machinists utilize it to make parts such as kitchenware, parachute canopies, automobile components, etc.

Surface Finishes

While metal has a wide array of surface finishes selections, the same can not be stated concerning plastics. If the machining is done appropriately, the usage of surface area coatings could not be needed. Examples of prominent CNC plastic surfaces include:

- Bead blasting entails utilizing pressed air to blast an abrasive material against the surface of a plastic material.

- Paint includes spraying paint onto the surface of the plastic component. It helps to improve the visual charm of a plastic part. It additionally offers protection to the plastic surface.

Machine Setup

In plastic model machining, establishing the devices intended for use is equally as vital as choosing the devices. This is because plastic is softer than steel, and also it is easier to leave a mark on its surface area. To prevent this as well as a few other mistakes throughout manufacturing, right here a couple of tips to keep in mind when establishing plastic machining devices:

- There should be a soft pad between the products as well as the reducing tool prior to machining beginnings. This will certainly help to minimize the force with which the equipment clamps down on the material. In this manner, you can decrease the incidence of cutting marks on the material.

- This is since the boring place always attempts to draw the part up throughout the machining process. If the drilling location is much from the fixtures, the drill will easily draw up the material.

- Last but not least, the machinist ought to have a coolant positioned straight at the point of the reducing tool. This will help cool down the temperature of the plastic throughout reducing and stop melting.

To Sum Up

Machining plastics is a popular machining process that has various applications in different markets across the world. Utilizing this machining process calls for a specialist factory’s solutions to help make your job a success. Making use of DEK is an outstanding choice you can make for your plastic machining tasks.