Summary of CNC Machining for Aerospace

CNC machining modern technology can not just ensure the precision and also the quality of aviation parts, but likewise boost the efficiency, which is conducive to the production of a range of an average and tiny set of CNC aerospace parts get rid of high performance. What are the attributes of aircraft components created with CNC machines? What issues at the same time as well as just how to resolve them?

CNC Aerospace parts Machining Characteristics

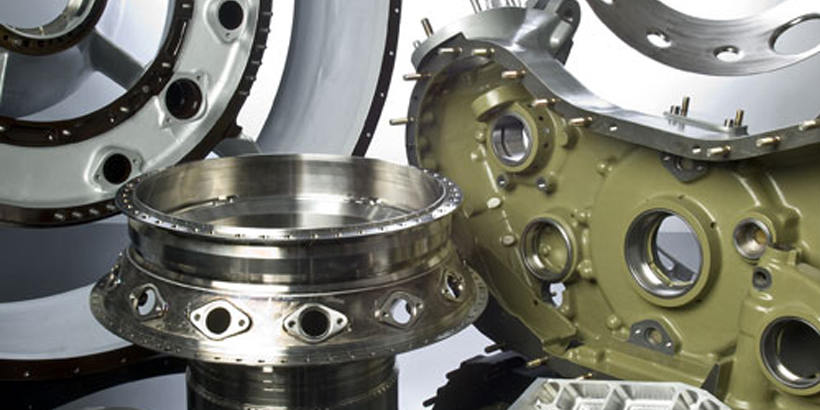

Compared with other sectors, aerospace parts have some amazing features. Aerospace parts made in elegant structure, high machining precision, steady and dependable top quality, so a multitude of monotonous machines, machining facilities, as well as other processing equipment with high machining precision and low surface roughness are utilized. DEK processes aerospace CNC machined parts in stringent conformity with the given requirements, and also the processing, as well as evaluation of each part, are taped thoroughly to make the parts traceable.

Top-quality requirements

Security is of vital importance throughout the flight, so strict quality assurance of aerospace parts is required.

Numerous materials

In order to lower the structural mass of the aircraft, in addition to using sensible frameworks, the most reliable approach is to pick materials with high stamina, high rigidity, and also lightweight. Secondly, according to different trip conditions as well as working environments, the products are called for to have particular high/low-temperature resistance, corrosion resistance, and also more performance. The frequently used aerospace materials are lightweight aluminum alloy, magnesium alloy, alloy steel, titanium alloy, composite product, and so on.

The large material removal rate

In a lot of cases, the material removal rate of an aircraft part is more than 90%, the reducing efficiency has a fantastic impact on the production cycle and cost.

Integrated framework

The design of aeronautics parts often tends to be a lot more complicated as well as incorporated with the development of contemporary aerospace and also CNC innovation, which streamlines the assembly and boosts the architectural performance, which likewise makes the CNC machining process harder.

Thin-wall and plus size

In order to regulate the weight of the airplane, an impressive function of the parts are thin-walled, furthermore, lots of parts of large aircraft are in plus size, the deformation must be purely managed during the manufacturing procedure.

Complex, small-batch, and also varied types

As a result of the complexity as well as a range of modern airplane parts, it is difficult to make use of large-scale production line manufacturing to boost effectiveness and also lower costs, the CNC machining aerospace parts also adjust to small set manufacturing.

Troubles in CNC Machining for Aerospace Components

- In the process of CNC machining, program adjustment, fixture prep work, device prep work, and components detection take up more time, as well as the machining effectiveness is decreased. The cutting efficiency is not high as well as the high-speed cutting application takes a low percentage.

- Mixed assembly line, reduced level of expertise and also integration, unreasonable format, cross manufacturing of numerous sorts of products, significantly limits the renovation of manufacturing performance.

- The advancement cost, as well as the danger, are high.

- A low degree of detail limits the effective procedure of production and research study.

- Deformation control of large frameworks is still an issue.

Exactly how to Address the Aerospace Parts Machining Issues

- Style the fixture appropriately and reduce the preparation as well as securing time off the work surface, boosts the performance and dependability.

- Based upon the item characteristics and also kinds split the manufacturing system into a specific assembly line.

- Apply CNC machining simulation innovation.

- Understand the info management and ideal arrangement of tools.

- Spend funds to broaden the tools scale, especially the big high-speed milling machines.