The Reason Why Small Dimensions Are A Big Deal in Manufacturing

Precision manufacturing indicates regularly producing parts that have measurements with extremely fine tolerances, normally gauged in microns or 10-6 meters. This is entirely possible when using good CAD/CAM digital tools and also modern-day, high-speed cutting tools.

However, there are some other useful factors to consider on the tiny range that surpass the equipment made use of because all materials normally expand and also acquire as a result of modifications in the atmosphere. So controlling resistances in the micron range can be extremely challenging. And also this is true for all major production procedures, not only CNC machining however additionally injection molding, pressure die spreading and 3D printing.

To understand far better the impact of tiny measurements on your completed components, allow’s very first take a look at exactly how small a micron actually is. Once we recognize that, it becomes much more clear that they look forever tighter measurements in manufactured items is not just pricey and unwise yet likewise unfavourable in the large bulk of cases.

Just how Little is a Micron?

To get a sense of the dimension of a micron it aids to imagine it in comparison to various other all-natural phenomena making use of powers of 10.

The above is from an impressive tool called the Range of deep space. It’s an interactive online application that begins with a human-sized object as an acquainted reference factor, and a meter as the initial dimension value.

A meter is a great starting location because we can then use powers of 10 to get down to a millimetre and also, from there, a micron. These are the measurements that are the most relevant for accurate manufacturing.

Reducing three powers often brings us to a millimetre, which is on the exact same scale as a big bacteria or a grain of salt. The majority of us can see a millimetre when it’s etched right into a finely finished direct scale.

But can you see one-tenth of a millimetre? That would be 10-4, which is currently at the limit of alone vision. And this number, tiny though it might seem, is still one hundred times larger than a micron at 10-6.

It’s important to note this not only because it’s trendy (it is), yet also to highlight that dimension dimensions and also producing on this range begin to bump up against certain physical limits. In this instance, thermal development and also a contraction of the workpiece, as well as resonance in the cutting tool, has an outsized influence on the completed item.

One more means this comes to be even more clear is to compare the micron with other all-natural phenomena. It is smaller sized, for instance than a wavelength of microwave radiation, and in the same range as a violet light. This is essential since it shows that at that range, min variations in energy produce visible changes in physical measurement.

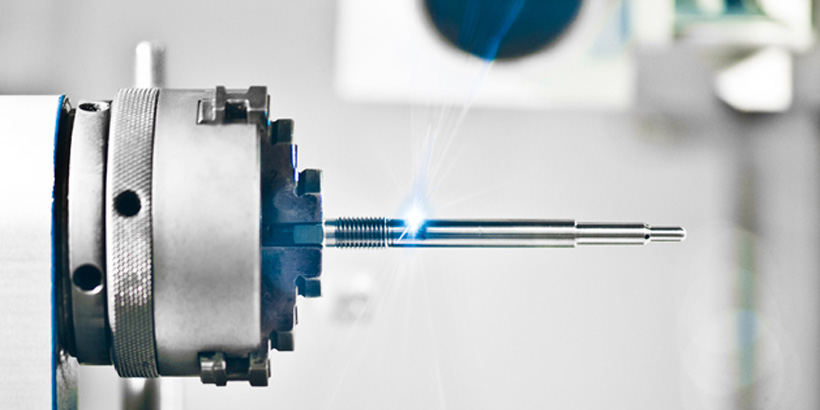

When a manufacturer is able to make a CNC turned component with a tolerance of +/- 10 microns, which we at Celebrity Rapid regularly do, they are effectively slicing a human hair into 20 or even more layers. Do you actually require this level of refinement for every job?

Why Tiny Dimensions Can Trigger Huge Issues

To maintain dimensions like these calls forever before more cautious craftsmanship and stiff environmental controls. This, in turn, significantly increases prices and production time. Paradoxically, exacting tolerances can hinder performance in numerous applications.

They need to otherwise glide previous one another, spin this method and that, open and also close, as well as be qualified of fitting with various other parts. If something is too specific it will certainly seize and also bind up. It will be unrelenting of friction as well as will instantly be “out-of-spec” the minute it’s exposed to heat, chilly, dirt– also fingerprints or water vapour!

Going after exactitude in one location of a part triggers you to shed it in another. This is because parts need to be clamped in holding components as they are machined, which certainly misshapes some dimensions. This exact same caution puts on cast or injection formed components that must have free space in order to be launched from their dies.

Suggestion

In general, 10 microns is good enough for precision bearings, shafts and other rotational parts. CNC milling of metals provides 20 ~ 50 microns easily, enough for rooms as well as structural parts. Plastic injection molded components are much more flexible of these resistances. We can provide you with even more certain guidance and a complete review that will certainly conserve your time and money when you contact us for a cost-free quotation.